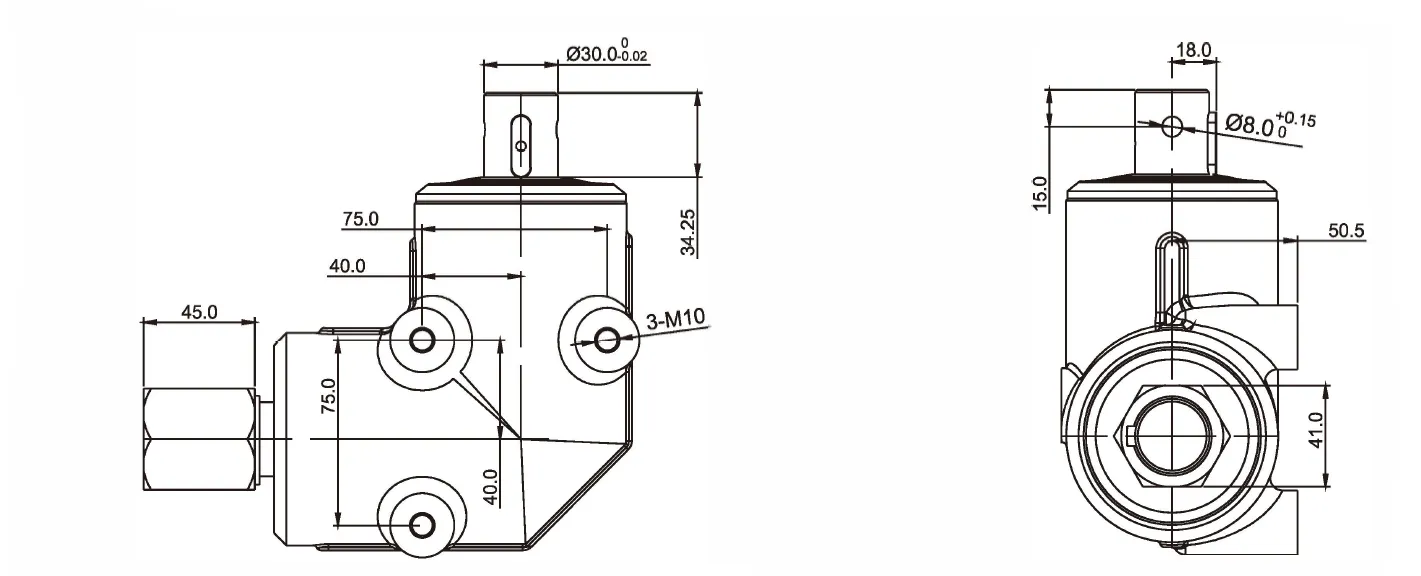

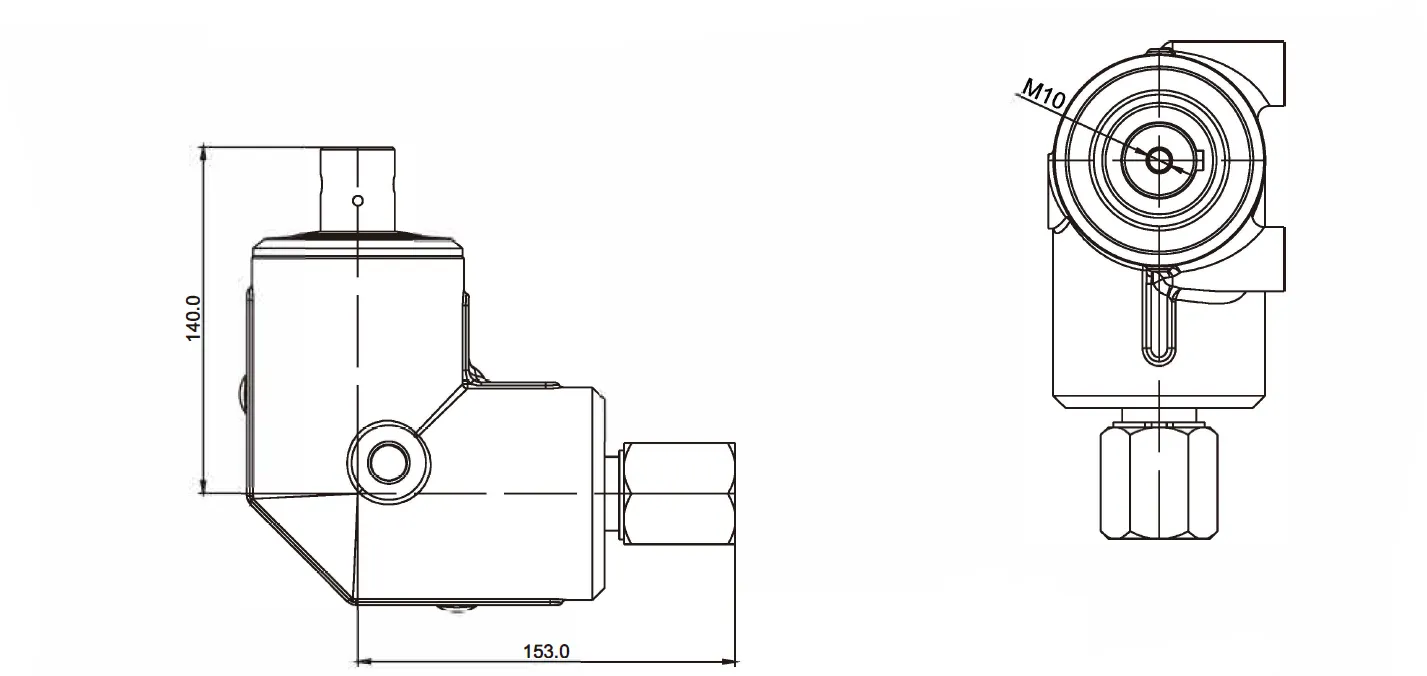

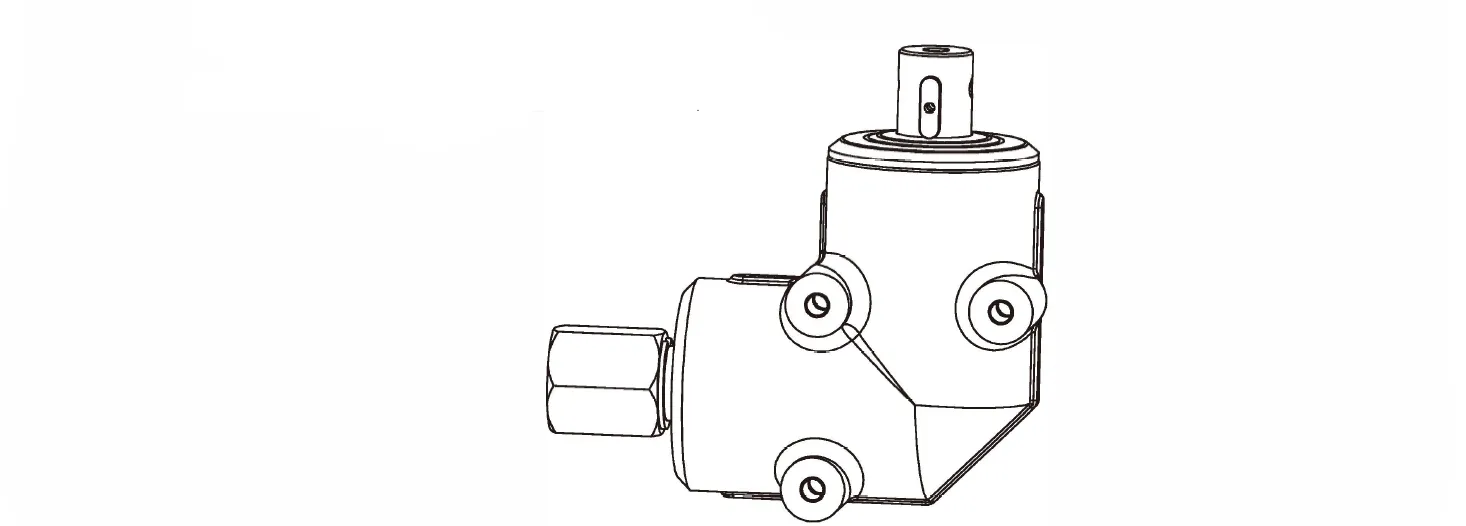

Double Disc Fertilizer Spreader Gearbox FMP-SF10 Dimensions

Double Disc Fertilizer Spreader Gearbox FMP-SF10 Technical Data

| i | Suitable | Rpm input | Rpm output | Power | Toothing | ||

| r/min | r/min | Kw | Hp | ||||

| left/right box | 1 :1.33 | Fertilizer spreader, etc | 540 | 406 | 15 | 20 | Gleason Helical Teeth |

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

Double Disc Fertilizer Spreader Gearbox FMP-SF10 Working Principle

The Double Disc Fertilizer Spreader Gearbox FMP-SF10 is a key component in fertilizer spreaders, particularly those used for broadcasting granular fertilizers in agricultural fields. Its working principle involves efficient power transmission from the tractor’s PTO (Power Take-Off) system to the rotating discs, which distribute fertilizer uniformly across the soil. Below is an overview of the working principle of the FMP-SF10 gearbox:

1. Power Transmission from PTO

- Input Power: The gearbox receives power from the tractor’s PTO shaft, which drives the gearbox to initiate the fertilizer spreading mechanism.

- Power Flow: The gearbox transfers the mechanical energy received from the PTO to the various moving parts of the spreader, ensuring efficient operation.

2. Gearbox Functionality

- Reduction Gear Mechanism: The gearbox contains a series of reduction gears that reduce the speed of the input power coming from the PTO, converting it to the optimal speed for the fertilizer spreader. This ensures that the rotation of the discs is controlled, which is essential for accurate fertilizer distribution.

- Speed Control: Depending on the requirements of the spreader, the gearbox can adjust the rotation speed of the discs. This speed adjustment allows for fine-tuning of the spreader’s fertilizer output, ensuring uniform coverage and avoiding over- or under-spreading.

3. Driving the Spreading Discs

- Disc Rotation: The power from the gearbox drives two spinning discs, which are positioned at the rear of the spreader. The discs rotate at high speeds and propel the fertilizer outward.

- Fertilizer Distribution: The fertilizer is spread across the field as the discs spin, with the gearbox ensuring consistent and even rotation. The centrifugal force generated by the discs pushes the fertilizer outward in a controlled manner, allowing for uniform coverage over a wide area.

4. Precision Control

- Adjustable Output: The FMP-SF10 gearbox enables operators to adjust the flow rate of fertilizer being distributed by modifying the speed of the discs or altering the settings of the gearbox. This control is crucial for applying the correct amount of fertilizer based on the field size, crop requirements, and soil conditions.

5. Robust Construction

- Durability: The gearbox is designed for heavy-duty operation in harsh agricultural environments. It is built to withstand the stresses of continuous operation and to provide reliable service across a wide range of operating conditions.

The FMP-SF10 gearbox functions as the driving force behind the uniform spreading of fertilizer in double disc fertilizer spreaders. By efficiently transmitting and reducing the speed of power from the PTO, it drives the spinning discs that broadcast fertilizer evenly across large areas. This ensures accurate fertilizer application, maximizing crop productivity and minimizing resource waste. The ability to control speed and flow rate further enhances its versatility, making it an essential component for modern agricultural operations.

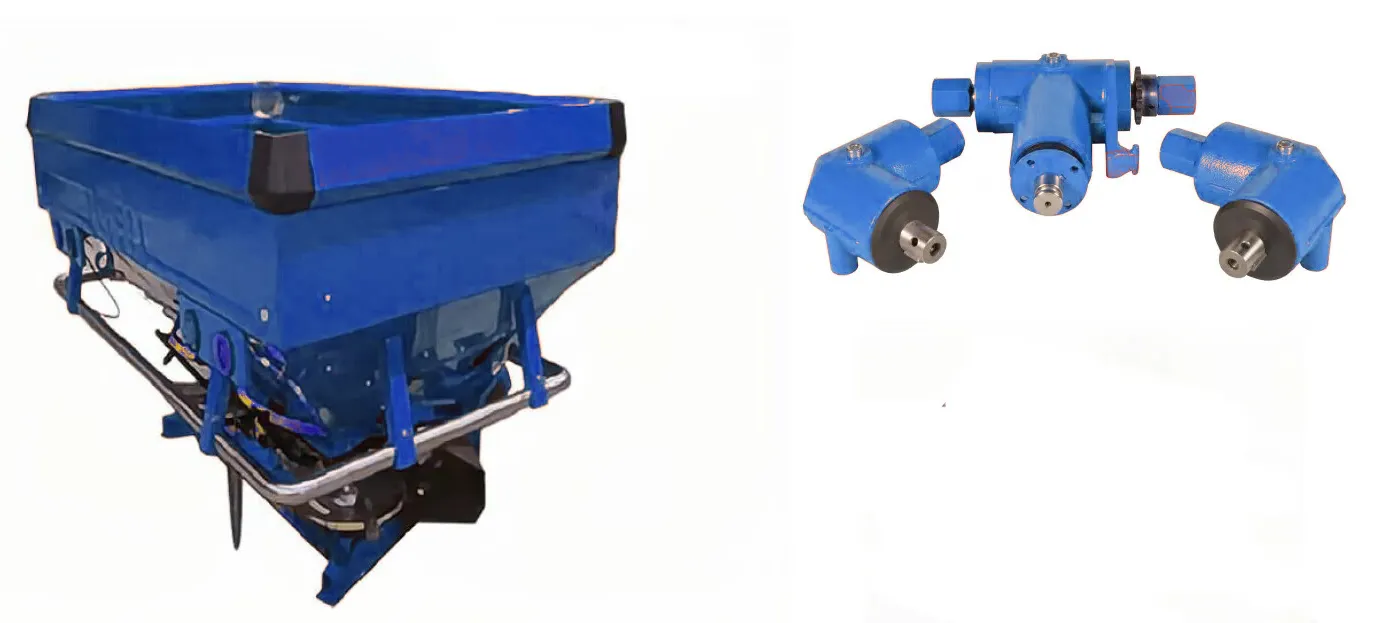

- Broadcaster Fertilizer Spreaders: The FMP-SF10 gearbox is primarily used in double-disc fertilizer spreaders, which are commonly employed in large-scale farming operations. It ensures uniform distribution of fertilizers over the field, enhancing crop growth and productivity.

- Granular Fertilizer Distribution: The gearbox drives the spreading discs to broadcast granular fertilizers across broad areas, ensuring even coverage for optimal nutrient distribution.

2. Precision Agriculture

- Variable Rate Application: The FMP-SF10 gearbox, with its precise control of disc rotation speed, is used in modern farming systems that require variable rate fertilizer application. It allows for accurate control over the amount of fertilizer spread, optimizing the efficiency of nutrient use based on soil conditions, crop type, and field variations.

- Efficient Fertilizer Management: With its adjustable output, the gearbox helps achieve consistent results in precision agriculture, where precise control over fertilizer usage is essential for reducing costs and environmental impact.

3. Lawn and Turf Management

- Sports Fields and Golf Courses: The gearbox is used in fertilizer spreaders that treat lawns, sports fields, and golf courses. The uniform distribution ensures that these areas receive the appropriate nutrient levels for healthy, even grass growth.

- Turf Care: The FMP-SF10 is a reliable choice for turf care equipment, where precise and efficient fertilizer spreading is necessary for maintaining high-quality green spaces.

4. Horticulture and Orchard Management

- Tree and Orchard Fertilization: In orchards, vineyards, and other horticultural settings, the gearbox drives the discs of specialized spreaders to deliver fertilizers efficiently between rows of trees or plants. It ensures consistent nutrient application, which is essential for healthy plant growth and fruit production.

- Row Crops: The gearbox can also be used in spreaders for row crops, helping to maintain a consistent and uniform fertilization process in crop production fields.

5. Landscaping and Turf Maintenance

- Landscape Fertilizer Spreaders: The FMP-SF10 gearbox is also applied in landscaping equipment for residential, commercial, and municipal projects. It powers the spreading discs, making it ideal for fertilizer applications in public spaces, parks, and large estates.

- Public Parks and Green Spaces: Urban landscaping and public green space management often use spreaders powered by gearboxes like the FMP-SF10 to maintain optimal soil health.

The FMP-SF10 Double Disc Fertilizer Spreader Gearbox is ideal for a variety of agricultural applications, including large-scale farming, precision agriculture, turf and lawn care, horticulture, landscaping, and soil management. It provides consistent, efficient, and controlled fertilizer distribution, contributing to improved crop yield, soil health, and overall agricultural productivity.

|

|

About FMP

Headquartered in Italy, FMP is a premier manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, with a special focus on the agricultural machinery sector. Known for precision engineering, innovative solutions, and steadfast reliability, FMP has established itself as a trusted partner in both the agricultural and industrial markets. Our broad product portfolio includes custom-designed gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously crafted to meet the diverse needs of various applications.

At FMP, we understand that each client faces unique challenges. That’s why we specialize in delivering tailored solutions, whether for individual components or fully integrated systems. Through close collaboration with our clients, we ensure that every solution not only meets their specific needs but also optimizes performance and maximizes value. Our commitment to prompt, professional responses and expert guidance ensures each inquiry is handled with precision, delivering the best possible outcomes.

We prioritize clear, ongoing communication throughout the entire product development cycle. Our dedicated team works directly with clients to fully understand their requirements and offer valuable insights and recommendations for achieving optimal results. Whether we’re designing state-of-the-art products or fulfilling routine orders, FMP is committed to providing high-quality, precision-engineered solutions on time, every time. Our mission is to consistently exceed client expectations, delivering exceptional service and results with each project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards and implement stringent quality control processes to ensure each product not only meets but exceeds industry benchmarks. This dedication to excellence, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to foster global partnerships, offering expert advice and customized solutions that address the evolving needs of our clients. We aim to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you’re seeking innovative solutions for a new initiative or require ongoing support for an existing system, FMP is ready to help you tackle your technical challenges and ensure your continued success.

Author: CX