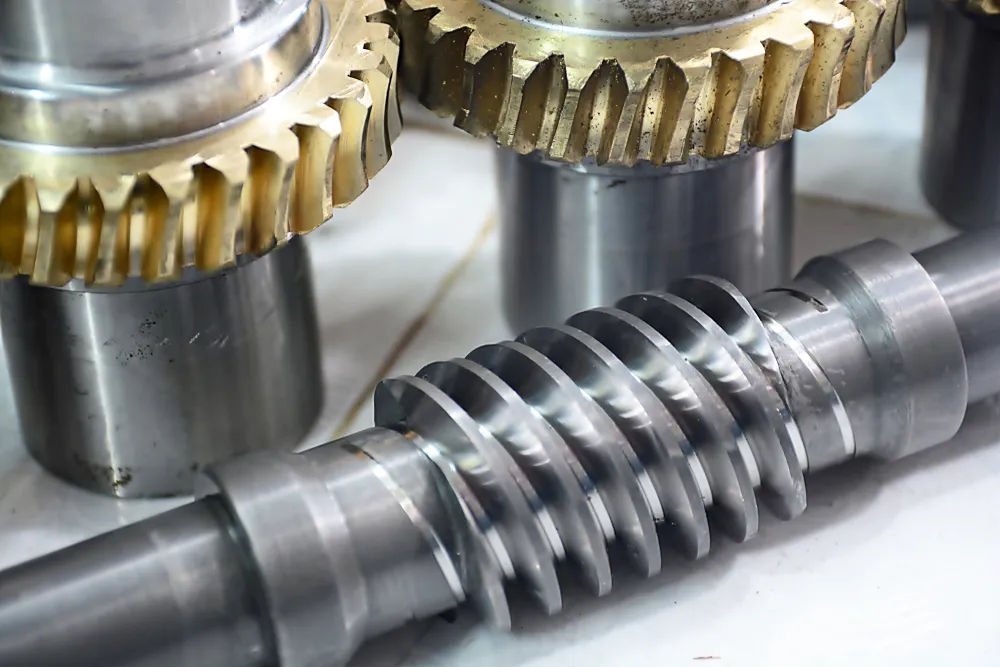

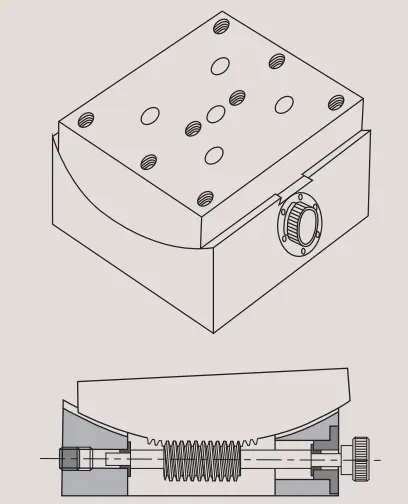

Custom worm gear sets

Custom worm gear sets are produced in various designs and materials according to customer specifications.

FMP offers custom gear sets with axial distances from 17 to 210 mm and a maximum worm wheel diameter of 300 mm. If necessary, FMP calculates the tooth profile data, defines the material and surface treatment, and provides consultation on lubrication and torque loads.

FMP has many years of experience in manufacturing worm gear sets, which means that our customers rely mainly on existing gear cutting tools, especially when dealing with short delivery times and small unit quantities. Therefore, the procedure must be checked on a case-by-case basis. To this end, you can contact us personally or use the request form.

|

|

|

|

Our Product

| Worm Gear Set | Center Distance (mm) | Gear Ratio | Output Torque (In lbs) |

|---|---|---|---|

| A17 | 17 | 2.25 – 80:1 | 8.85 – 24.78 |

| A22 | 22 | 3 – 40:1 | 19.47 – 51.33 |

| A25 | 25 | 4 – 50:1 | 45.14 – 82.3 |

| A31 | 31 | 2.5 – 100:1 | 89.39 – 122.94 |

| A33 | 33 | 3.5 – 75:1 | 89.39 – 188.52 |

| A35 | 35 | 2.78 – 90:1 | 58.4 – 226.58 |

| A40 | 40 | 6.75 – 90:1 | 223.004 – 411.56 |

| A50 | 50 | 4.25 – 69:1 | 300.9 – 1039.2 |

| A53 | 53 | 4.75 – 75:1 | 398.28 – 1247.9 |

| A63 | 63 | 6.1 – 70:1 | 787.7 – 2283.5 |

| A65 | 65 | 6.25 – 75:1 | 893.9 – 2549 |

| A80 | 80 | 6.75 – 80:1 | 1327.6 – 4620 |

| Gear Types | spur gear, helical gear, internal spur gear, ring gear, straight/spiral bevel gear, hypoid gear,

crown wheel & pinion, gear shaft, worm gear & worm shaft, spline shaft & bushing, etc. |

| Gear Material | carbon steel, alloy steel, stainless steel, brass, bronze, cast iron, nylon, etc.

{ GB Steel: C45, 40Cr, 20CrMo, 20CrMoTi, 17CrNiMo6, 20CrMnTi, 42CrMo, etc. } |

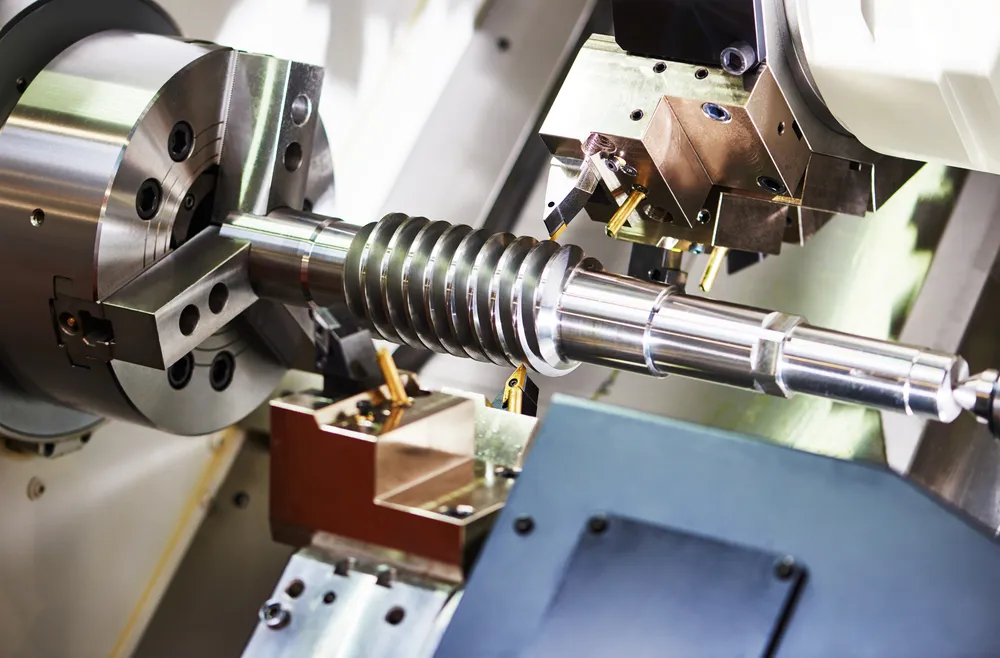

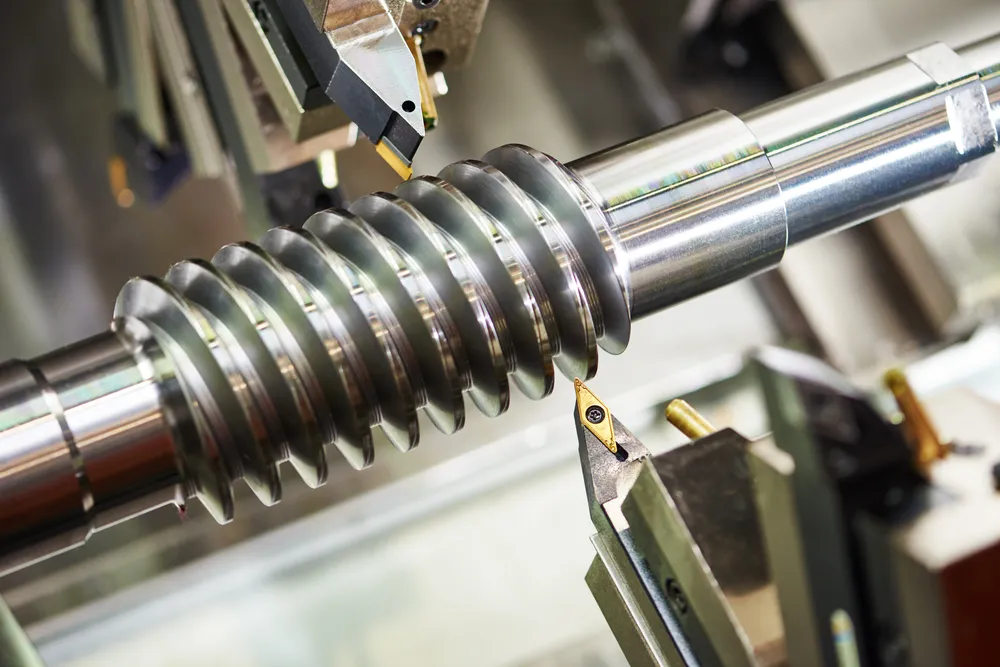

| Processing | gear blank turning, gear hobbing, gear milling, gear shaping, gear shaving, tooth grinding,

broaching, etc. |

| Heat Treating | quenching, carburizing, nitriding, carbon-nitriding, salt bath quenching, etc. |

| Application | Automotive, Agricultural, Electronic, Industrial, Medical, Defense, Off-highway, etc. |

Features of worm gear sets

|

|

|

| Smooth surface, no burr, no sharp corners | Strong and durable, large rotation ratio, small transmission power | The tooth surface of worm gear is linear contact and the bearing capacity is large |

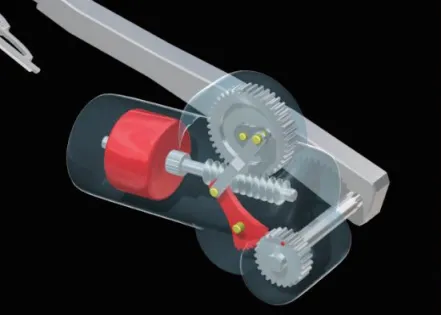

Application

| Wiper Drive Device | |

|

|

| Worm gear used for the oscillating mechanism of wipers | Worm gear used for the oscillating mechanism of wipers |

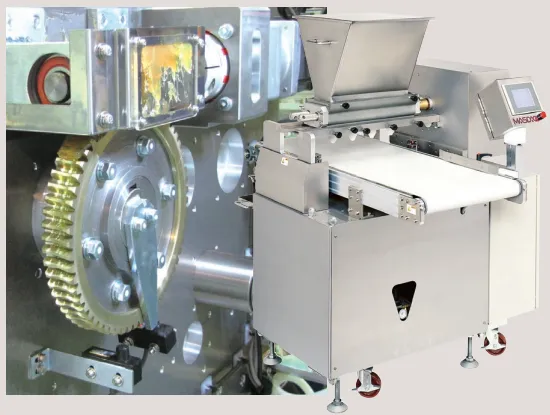

| Steam Kettle | Food Filling Device |

|

|

| worm and worm wheel used for rotating large pans | worm gear used for indexing and driving, for accurate filling of a fixed amount of ingredients |

| Stage Design Example | Fabric Feeding Device |

|

|

| Worm gear used for rotating tables (design example) | worm and worm wheel used for adjusting height |