Crane Pin Hydraulic Cylinder

The Crane Pin Hydraulic Cylinder is an essential component designed to facilitate the precise movement and secure locking of pins in various crane applications. This hydraulic cylinder provides reliable force to engage and disengage pins that connect different crane components, ensuring stability and safety during lifting operations.

Key Features:

- Durable Construction: Made from high-strength materials, the crane pin hydraulic cylinder is built to withstand the demanding conditions of construction and heavy lifting environments, ensuring long-lasting durability and reliability.

- Smooth Operation: The advanced hydraulic system allows for fluid and controlled movements, enabling quick and efficient engagement and disengagement of pins, which enhances the overall functionality of the crane.

- Enhanced Safety: By ensuring secure pin engagement, this hydraulic cylinder helps maintain the stability of crane components during operation, reducing the risk of accidents and improving safety for operators and site personnel.

- Versatile Application: Suitable for a wide range of cranes and lifting equipment, the pin hydraulic cylinder can be easily integrated into existing systems, making it a versatile solution for various lifting and construction tasks.

- Low Maintenance Requirements: Designed for efficiency and durability, this hydraulic cylinder requires minimal maintenance, contributing to reduced downtime and increased productivity.

The Crane Pin Hydraulic Cylinder is a crucial component that enhances the performance, safety, and reliability of cranes, making it indispensable for effective lifting operations in diverse applications.

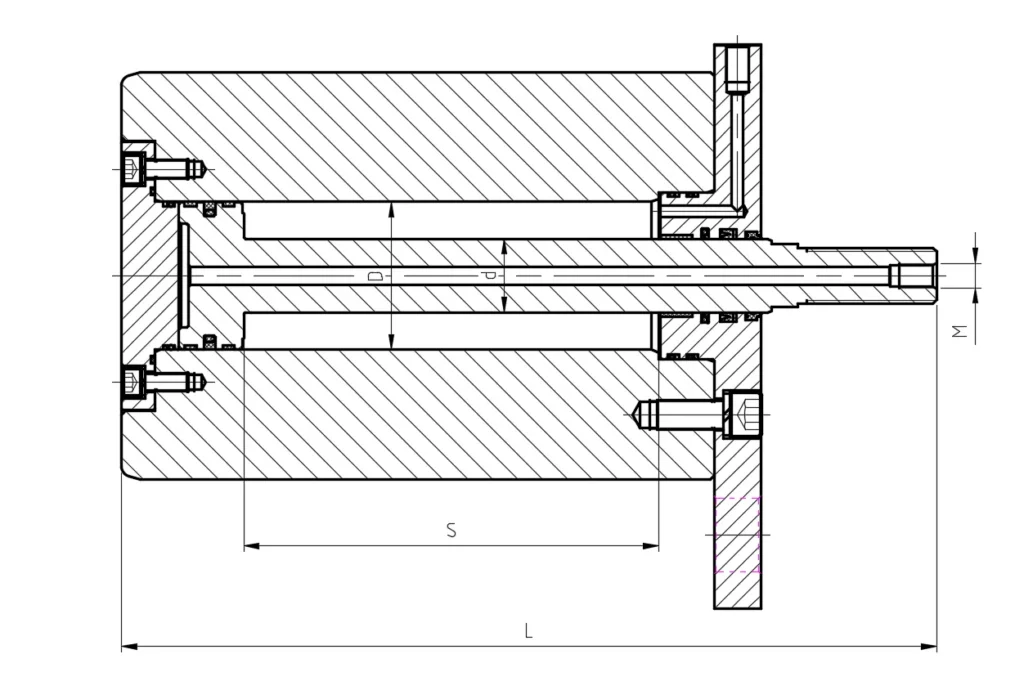

Crane Pin Hydraulic Cylinder Dimensions:

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Pin hydraulic cylinder | ZXYG14.01-00 | Φ80 | Φ40 | 225 | 440 | 25MPa | G1/4 | 97.8kg |

Crane Pin Hydraulic Cylinder Parameter:

| Item | Description |

| Product Name | Custom-made hydraulic Cylinder |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | FMP or customer’s logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Hydraulic Cylinder Available Brand & Models:

| KOMATSU (PC) | PC30,PC40,PC50,PC56,PC60,PC78,PC100,PC110,PC120,PC130,PC160,PC200-3/5/6/7/8/8MO,PC210,PC220-5/6/7/8/8MO,PC240,PC300/350/360-5/6/7/8/8MO,PC400/450-5/6/7/8/8MO,PC800,PC850 |

| CATERPILLAR (E) | E301.5,E302,E305.5,E306,E307V1/V2/B/C/D/E/F,E308B/C,E120B,E312V1/V2/B/C/D,E313D2,E312D2,E315D, E200B,E320V1/V2/A/B/C/D,E324D,E325C/D,E329D,E330/336C/D,E345C,E349D,E365C,E374,E390 |

| KOBELCO (SK) | SK60-3/5/8,SK75-8/SR, SK100 ,SK120-3/5, SK135-8/SR, SK140-8, SK200-3/5/6/6E, SK210-3/5/6/6E, SK230/250-6E,SK250-8,SK260-8,SK350-8/S8,SK460/480-8 |

| HYUNDAI (R) | R55-5/7, R60-5/7, R80, R110,R130, R200-5, R210-5, R215-5/7,R220-5/7/9, R225-5/7/9, R250,R260,R265,R290,R305,R445,R485, R505 |

| HITACHI (EX.ZX) | EX60,EX100-1/2/3,EX120-1/3/5/6,EX200-1/3/5,EX230-5,EX300-1,EX400 ZAX60,ZAX70,ZA120-6,ZAX200/210-1/3/5/5K,ZAX240,ZAX250,ZAX260,ZAX330-3/5/6,ZAX450/470,ZAX650/670,ZAX850/870 |

|

DOOSAN (DH/DX)

|

DH55, DH60, DH80,DH150, DH215-5/7,DH220-5,DH225-5/7,DH258,DH300-5/7, DH370,DH420,DH500

DX55,DX60,DX75,DX130,DX225-9,DX300,DX380,DX420,DX500 |

|

VOLVO (EC)

|

EC55 ,EC60,EC75,EC80,EC140 ,EC210B/D,EC220D,EC240 ,EC250,EC290,EC300, EC360 EC380,EC460,EC480,EC700,EC750,EC950

|

|

KATO (HD)

|

HD307/308,HD450,HD512,HD700-5/7,HD820-1/2/3/5/R,HD1023-1/3,HD1430-1/3

|

|

OTHER BRAND

|

XCMG,LIUGONG,KUBOTA,CASE,YANMAR,SUNWARD,ZOOMLION,LISHIDE,LIEHERR

|

Advantages of Crane Pin Hydraulic Cylinder

1. Precise Engagement and Disengagement

The Crane Pin Hydraulic Cylinder allows for accurate control over the engagement and disengagement of pins, ensuring that crane components are securely locked during operation. This precision enhances safety and operational efficiency.

2. Enhanced Stability

By providing reliable locking mechanisms, this hydraulic cylinder ensures that crane components remain stable during lifting operations. This stability reduces the risk of accidents and improves overall safety for operators and surrounding personnel.

3. Durable Construction

Constructed from high-strength materials, the crane pin hydraulic cylinder is designed to withstand the demanding conditions of construction and heavy lifting. Its robust design ensures long-lasting durability and reliability in harsh environments.

4. Smooth Operation

The advanced hydraulic system facilitates smooth and controlled movements, allowing for quick adjustments. This efficiency enhances the crane’s performance and enables faster cycle times during operations.

5. Versatile Application

This hydraulic cylinder is suitable for a wide range of crane types and lifting equipment, making it a versatile solution for various applications in construction, maintenance, and industrial settings.

6. Low Maintenance Needs

The design minimizes wear and tear, leading to reduced maintenance requirements. This results in lower operational costs and less downtime, contributing to overall productivity.

7. Energy Efficiency

The hydraulic system is optimized for energy use, reducing power consumption during operation. This efficiency not only lowers operational costs but also supports environmentally friendly practices in lifting operations.

The Crane Pin Hydraulic Cylinder offers numerous advantages, including precise control, enhanced stability, and durability, making it an indispensable component for effective and reliable crane operations in various applications.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX