Crane Boom Anti Tilt Hydraulic Cylinder

The Crane Boom Anti-Tilt Hydraulic Cylinder is an essential component designed to enhance the stability and safety of crane operations by preventing boom tilt during lifting. This hydraulic cylinder provides precise control over the boom’s angle, ensuring that it remains level even when handling heavy loads.

Key Features:

- Durable Construction: Made from high-strength materials, this hydraulic cylinder is engineered to withstand the demanding conditions of construction and industrial environments, ensuring long-lasting durability and reliability.

- Enhanced Stability: By preventing the tilting of the crane boom, this cylinder helps maintain optimal balance, reducing the risk of accidents and improving overall safety for operators and site personnel.

- Smooth Hydraulic Operation: The advanced hydraulic system allows for fluid and controlled movements, enabling quick adjustments to the boom’s position without compromising stability.

- Versatile Application: Suitable for a wide range of cranes, including tower cranes and mobile cranes, the anti-tilt hydraulic cylinder can be easily integrated into various lifting systems, making it a versatile solution.

- Low Maintenance Requirements: Designed for efficiency and durability, this hydraulic cylinder requires minimal maintenance, contributing to reduced downtime and increased productivity.

In summary, the Crane Boom Anti-Tilt Hydraulic Cylinder is a vital component that enhances crane performance and safety by ensuring stability during lifting operations, making it indispensable for effective and reliable lifting applications.

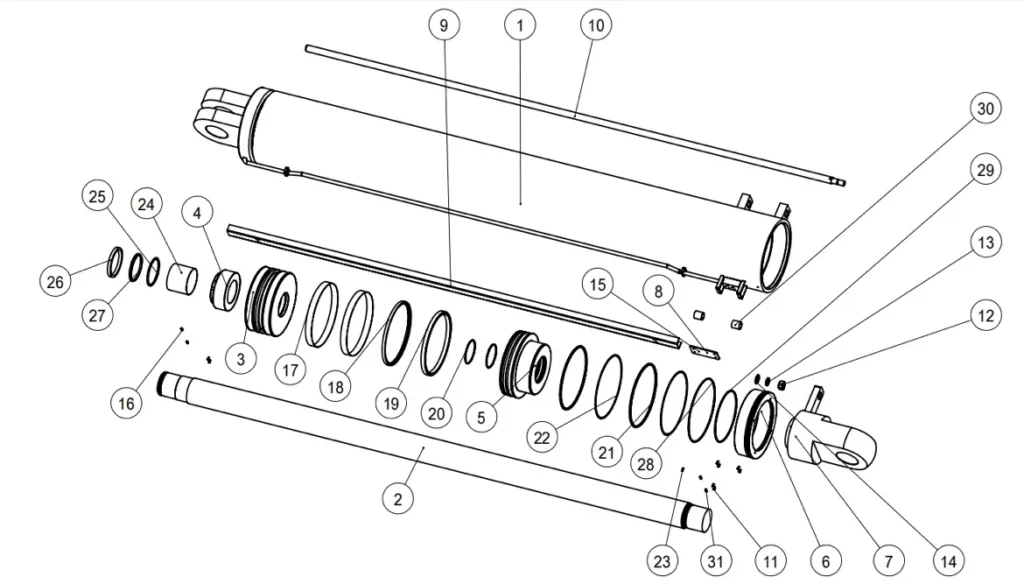

Crane Boom Anti Tilt Hydraulic Cylinder Parts:

|

1

|

Cylinder Housing assy

|

12

|

Nut

|

23

|

Set Screws

|

|

2

|

Piston Rod

|

13

|

Spring Washers

|

24

|

Du Bush

|

|

3

|

Piston

|

14

|

Flat Washers

|

25

|

Rod Seal

|

|

4

|

Lock Nut

|

15

|

Valve Cover

|

26

|

U-Ring

|

|

5

|

Guide Bush

|

16

|

Set Screws

|

27

|

Dust Wiper

|

|

6

|

Gland

|

17

|

Wear-Ring

|

28

|

O-Ring

|

|

7

|

Clevis

|

18

|

Hole Seal

|

29

|

O-Ring

|

|

8

|

Dust Cover

|

19

|

U-Ring

|

30

|

Du Bush

|

|

9

|

Oil Pipe Cover

|

20

|

O-Ring

|

31

|

Set Screws

|

|

10

|

Guide rod

|

21

|

O-Ring

|

||

|

11

|

Bolt

|

22

|

Back-Ring

|

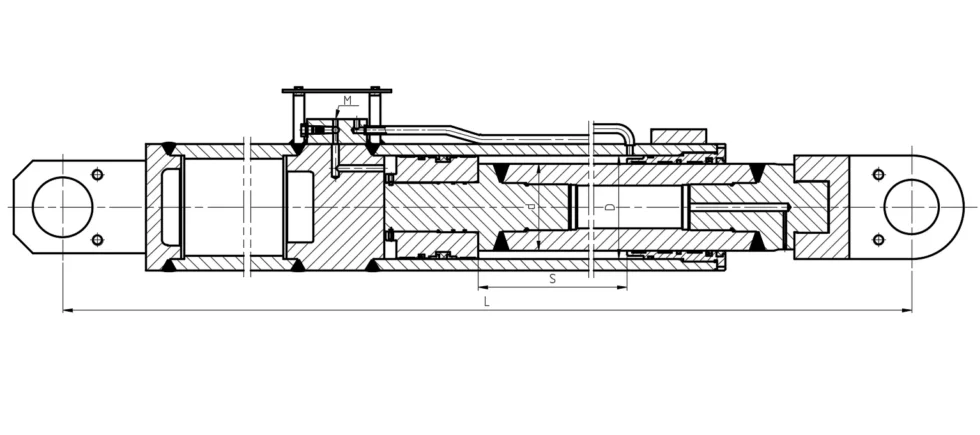

Crane Boom Anti Tilt Hydraulic Cylinder Dimensions:

|

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Boom anti-tilt hydraulic cylinder | ZXYG17.04-00 | Φ190 | Φ160 | 1400 | 4300 | 31.5MPa | G1/4;2-Φ9 | 820kg |

Hydraulic Cylinder Available Brand & Models:

| KOMATSU (PC) | PC30,PC40,PC50,PC56,PC60,PC78,PC100,PC110,PC120,PC130,PC160,PC200-3/5/6/7/8/8MO,PC210,PC220-5/6/7/8/8MO,PC240,PC300/350/360-5/6/7/8/8MO,PC400/450-5/6/7/8/8MO,PC800,PC850 |

| CATERPILLAR (E) | E301.5,E302,E305.5,E306,E307V1/V2/B/C/D/E/F,E308B/C,E120B,E312V1/V2/B/C/D,E313D2,E312D2,E315D, E200B,E320V1/V2/A/B/C/D,E324D,E325C/D,E329D,E330/336C/D,E345C,E349D,E365C,E374,E390 |

| KOBELCO (SK) | SK60-3/5/8,SK75-8/SR, SK100 ,SK120-3/5, SK135-8/SR, SK140-8, SK200-3/5/6/6E, SK210-3/5/6/6E, SK230/250-6E,SK250-8,SK260-8,SK350-8/S8,SK460/480-8 |

| HYUNDAI (R) | R55-5/7, R60-5/7, R80, R110,R130, R200-5, R210-5, R215-5/7,R220-5/7/9, R225-5/7/9, R250,R260,R265,R290,R305,R445,R485, R505 |

| HITACHI (EX.ZX) | EX60,EX100-1/2/3,EX120-1/3/5/6,EX200-1/3/5,EX230-5,EX300-1,EX400 ZAX60,ZAX70,ZA120-6,ZAX200/210-1/3/5/5K,ZAX240,ZAX250,ZAX260,ZAX330-3/5/6,ZAX450/470,ZAX650/670,ZAX850/870 |

|

DOOSAN (DH/DX)

|

DH55, DH60, DH80,DH150, DH215-5/7,DH220-5,DH225-5/7,DH258,DH300-5/7, DH370,DH420,DH500

DX55,DX60,DX75,DX130,DX225-9,DX300,DX380,DX420,DX500 |

|

VOLVO (EC)

|

EC55 ,EC60,EC75,EC80,EC140 ,EC210B/D,EC220D,EC240 ,EC250,EC290,EC300, EC360 EC380,EC460,EC480,EC700,EC750,EC950

|

|

KATO (HD)

|

HD307/308,HD450,HD512,HD700-5/7,HD820-1/2/3/5/R,HD1023-1/3,HD1430-1/3

|

|

OTHER BRAND

|

XCMG,LIUGONG,KUBOTA,CASE,YANMAR,SUNWARD,ZOOMLION,LISHIDE,LIEHERR

|

Advantages of Crane Boom Anti-Tilt Hydraulic Cylinder

1. Enhanced Stability

The Crane Boom Anti-Tilt Hydraulic Cylinder is specifically designed to prevent the tilting of the boom during lifting operations. This stability is crucial for safely handling heavy loads and reduces the risk of accidents on the job site.

2. Improved Safety

By maintaining the crane boom in a level position, this hydraulic cylinder enhances overall safety for operators and personnel nearby. It minimizes the chances of boom failure or unintended movements, safeguarding both equipment and workers.

3. Precise Control

The cylinder provides accurate control over the boom’s angle, allowing operators to make smooth adjustments. This precision is essential for navigating complex lifting tasks and optimizing performance in tight spaces.

4. Durable Construction

Built from high-strength materials, the anti-tilt hydraulic cylinder is designed to withstand the harsh conditions of construction and industrial environments. Its robust construction ensures long-lasting durability and reliability.

5. Versatile Application

This hydraulic cylinder is compatible with a variety of crane types, including tower cranes and mobile cranes. Its versatility makes it suitable for different lifting applications across various industries.

6. Low Maintenance Requirements

The design of the anti-tilt hydraulic cylinder minimizes wear and tear, resulting in lower maintenance needs. This leads to reduced downtime and operational costs, contributing to greater efficiency.

7. Energy Efficiency

The hydraulic system is optimized for energy use, reducing power consumption during operation. This efficiency not only lowers operational costs but also supports more sustainable practices in crane operations.

The Crane Boom Anti-Tilt Hydraulic Cylinder offers numerous advantages, including enhanced stability, improved safety, and precise control, making it an indispensable component for effective and reliable crane operations across various applications.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX