|

|

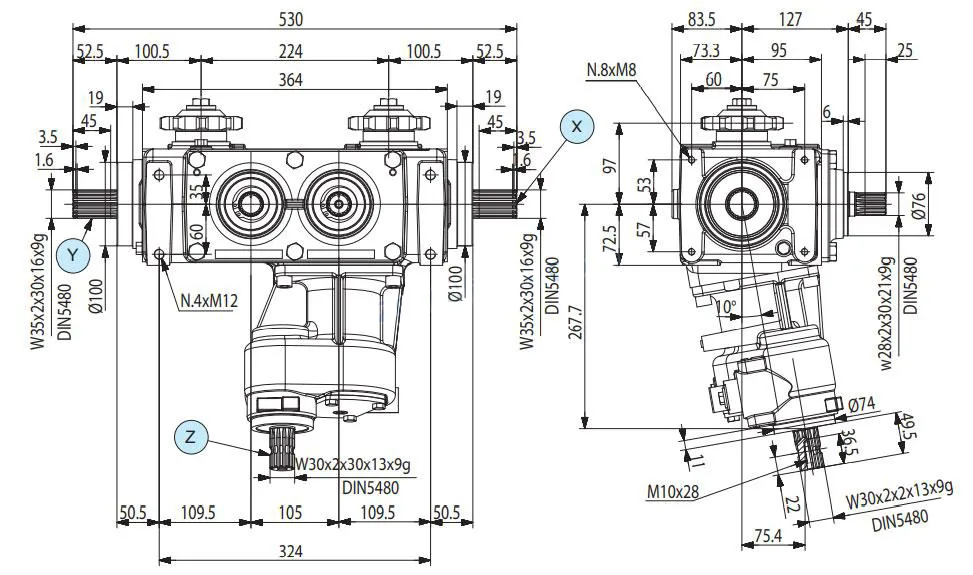

Specification of Corn Headers Gearbox

|

|

|

Features of Corn Header Gearbox

The corn header gearbox is a crucial component in the harvesting machinery used to efficiently harvest corn crops. It provides the necessary power and mechanical advantage to operate the header system, ensuring optimal performance and productivity. Here are some of the key features of a corn header gearbox:

1. High Torque Transmission

- The gearbox is designed to transmit high torque from the tractor’s PTO to the corn header. This ensures that the various moving parts of the header, such as the gathering chains and stripper plates, operate smoothly even under heavy load conditions.

2. Precision Engineering

- Corn header gearboxes are engineered with precision to ensure smooth operation and durability. The components are designed to minimize wear and tear, ensuring longevity and consistent performance.

3. Durability and Strength

- These gearboxes are built to withstand harsh field conditions, including exposure to dust, moisture, and extreme temperatures. High-quality materials are used to ensure that the gearbox can handle the high demands of continuous use during harvest seasons.

4. Efficient Power Transfer

- Corn header gearboxes are designed to efficiently transfer power from the tractor’s PTO shaft to the header components, minimizing energy loss and enhancing the efficiency of the harvesting process.

5. Compact and Robust Design

- The gearboxes are typically compact, making them easy to integrate into the header system without adding excessive weight or bulk. The robust design ensures that the gearbox can handle the constant wear and tear of agricultural use.

In conclusion, the corn header gearbox is engineered to deliver power, precision, and durability under tough conditions, enhancing the overall efficiency and reliability of the corn harvesting process.

PTO Shafts for Corn Headers Gearbox

The PTO (Power Take-Off) shaft is an essential component in connecting the tractor’s power system to the corn header gearbox. It transmits mechanical power from the tractor’s engine to the gearbox, enabling the corn header’s various mechanisms to function effectively during harvesting. Here are the key aspects of PTO shafts for corn header gearboxes:

1. Power Transfer

- The PTO shaft is designed to transfer mechanical power from the tractor’s PTO to the corn header gearbox. This power is then distributed to the header components such as gathering chains, augers, and other moving parts that assist in harvesting corn.

2. High Torque Capacity

- PTO shafts for corn header gearboxes are built to withstand high torque loads. Corn harvesting is a high-intensity operation, so the PTO shaft needs to handle substantial power without failure. The shaft is made from high-strength materials to ensure efficient power transfer even under heavy loads.

3. Universal Joint Design

- The PTO shaft is equipped with universal joints at both ends, allowing it to transmit power even when there is a slight angle or misalignment between the tractor’s PTO output and the corn header gearbox. This flexibility ensures smooth and uninterrupted operation while reducing the risk of wear.

4. Durability and Longevity

- These PTO shafts are designed to be robust and durable, as they are subject to harsh field conditions like dirt, moisture, and mechanical stress. The shafts are made from high-quality steel and often feature corrosion-resistant coatings to extend their lifespan.

5. Adjustable Length

- PTO shafts can be adjusted in length to accommodate different equipment sizes and configurations. This adjustability is particularly useful when attaching the PTO shaft from the tractor to various models of corn headers, as the connection length can vary.

PTO shafts for corn header gearboxes are vital components that facilitate the efficient transfer of power from the tractor to the header. They are designed to be durable, safe, and versatile, ensuring reliable performance and reducing downtime in demanding field conditions.

About FMP

Headquartered in Italy, FMP is a prominent manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a primary focus on agricultural machinery. Known for our precision engineering, innovative solutions, and unwavering reliability, FMP has earned a trusted reputation in both the agricultural and industrial sectors. Our extensive product portfolio includes custom-designed gearboxes for lawn mowers, PTO shafts, and a variety of essential components, all carefully engineered to meet the specific needs of diverse applications.

At FMP, we recognize that each client faces unique challenges. That’s why we specialize in delivering tailored solutions—whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only addresses their needs but also enhances performance and maximizes value. Our commitment to providing timely, professional responses and expert guidance ensures that every inquiry is handled with precision, consistently delivering optimal results.

We emphasize clear, continuous communication throughout the entire product development cycle. Our dedicated team works collaboratively with clients to fully understand their requirements and offer valuable insights and recommendations for achieving the best possible outcomes. Whether designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions, on time and with consistency. Our goal is to consistently exceed client expectations, providing exceptional service and results in every project.

Quality is the foundation of everything we do at FMP. We adhere to the highest manufacturing standards and implement stringent quality control processes to ensure that each product not only meets, but exceeds, industry standards. This commitment to excellence, combined with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always eager to forge global partnerships, offering expert advice and customized solutions that address the evolving needs of our clients. We aim to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you are seeking innovative solutions for a new initiative or require ongoing support for an existing system, FMP is ready to help you navigate technical challenges and ensure your continued success.

Author: CX