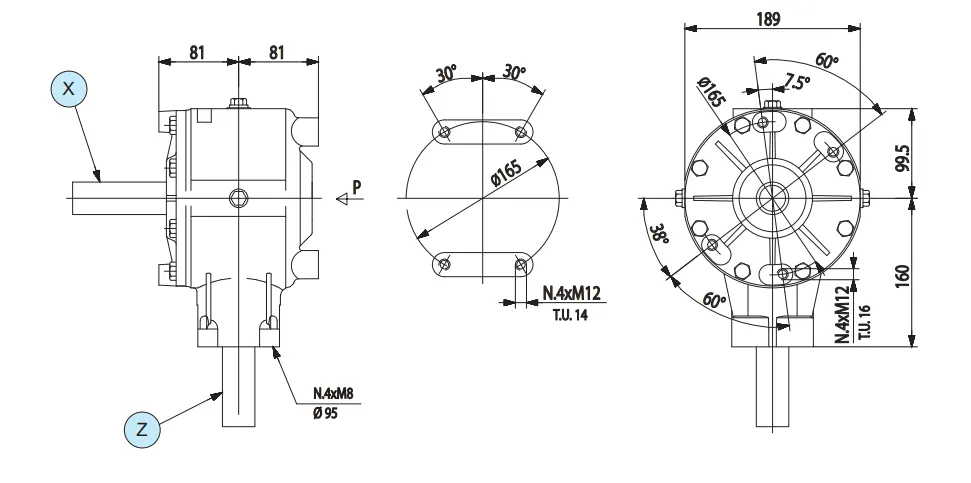

Specifications of Corn Header Gearbox T-304A

| Product details |

|

|---|---|

| Application range |

|

| Consists of |

|

Characteristics of Corn Header Gearboxes

- High Torque Capacity

Corn header gearboxes are designed to handle high torque loads, ensuring efficient power transmission from the tractor to the header mechanism. This is especially important for harvesting corn, as the gearbox needs to withstand the mechanical stress of cutting and gathering the crop. - Durable Construction

Built with robust materials such as high-grade steel or cast iron, corn header gearboxes are engineered for durability and longevity. These gearboxes are capable of performing in demanding agricultural environments, withstanding harsh weather conditions and prolonged operational hours. - Precision Engineering

Corn header gearboxes are designed with precision to ensure smooth and reliable operation. The gears within the gearbox are manufactured to tight tolerances, reducing friction and increasing efficiency, which in turn improves the performance of the entire harvesting system. - Compact and Efficient Design

These gearboxes are compact, yet powerful, making them ideal for integration into corn harvesting machinery where space is limited. Despite their small size, they are designed to handle significant power loads while maintaining operational efficiency. - Gear Ratios

Corn header gearboxes typically feature specific gear ratios optimized for the needs of corn harvesting. The right ratio ensures the right speed and power output to suit the cutting and gathering operations, improving the overall productivity and performance of the header.

In summary, PTO shafts are essential components that connect the tractor to the corn header gearbox, enabling efficient power transmission for the harvesting process. The right PTO shaft ensures reliable, safe, and efficient operation, contributing to higher productivity and reduced downtime during the harvest.

PTO Shafts for Corn Header Gearbox

PTO (Power Take-Off) shafts are critical components used to transfer mechanical power from the tractor’s engine to the corn header gearbox. The PTO shaft connects the tractor’s PTO output to the gearbox of the corn header, allowing power to be transmitted efficiently to drive the cutting and gathering mechanisms. Here’s an overview of the characteristics and considerations when selecting PTO shafts for corn header gearboxes:

- High Torque Transmission

PTO shafts for corn header gearboxes are designed to handle high torque loads that are required for operating the corn header’s cutting, gathering, and threshing mechanisms. The shaft must transfer substantial power from the tractor to the gearbox while maintaining smooth operation. - Durability and Strength

Built from high-quality materials such as high-strength steel or alloy metals, these PTO shafts are engineered for long-lasting durability. They are designed to resist wear and tear under the heavy-duty demands of agricultural machinery, ensuring a prolonged service life. - Universal Compatibility

PTO shafts for corn header gearboxes are often designed with universal joints, allowing them to be compatible with a variety of tractor models and corn header brands. This adaptability ensures that the PTO shaft can be easily integrated into different machines and operational setups. - Flexibility and Adjustability

PTO shafts are often equipped with telescoping sections, providing flexibility and ease of adjustment. This feature allows operators to adjust the length of the shaft to suit different tractor-to-header distances, facilitating proper alignment and reducing stress on the shaft and gearbox. - Efficient Power Transfer

These shafts are engineered to minimize energy loss during power transfer. A well-designed PTO shaft ensures that maximum power from the tractor engine is efficiently transmitted to the corn header gearbox, improving the overall efficiency of the harvesting process.

In summary, PTO shafts are essential components that connect the tractor to the corn header gearbox, enabling efficient power transmission for the harvesting process. The right PTO shaft ensures reliable, safe, and efficient operation, contributing to higher productivity and reduced downtime during the harvest.

About FMP

Headquartered in Italy, FMP is a prominent manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, with a primary focus on the agricultural machinery sector. Renowned for its precision engineering, innovative solutions, and consistent reliability, FMP has established a strong reputation as a trusted partner in both agricultural and industrial markets. Our diverse portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of other critical components, each meticulously designed to meet the specific demands of various applications.

At FMP, we recognize that every client faces unique challenges. This understanding drives our commitment to delivering tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only meets their specific needs but also optimizes performance and maximizes value. Our dedication to timely, professional responses and expert guidance ensures that every inquiry is handled with precision, consistently delivering optimal results.

We place a strong emphasis on transparent, ongoing communication throughout the entire product development cycle. Our dedicated team collaborates closely with clients to fully understand their requirements and provide valuable insights and recommendations to achieve the best outcomes. Whether designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to exceed client expectations, providing exceptional service and results with every project.

At the core of FMP’s operations is a steadfast commitment to quality. We adhere to the highest manufacturing standards and implement stringent quality control processes to ensure that each product not only meets but exceeds industry benchmarks. This unwavering focus on excellence, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

At FMP, we are always eager to foster global partnerships by offering expert advice and customized solutions that address the ever-evolving needs of our clients. We strive to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you are looking for innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you overcome technical challenges and ensure your continued success.

Author: CX