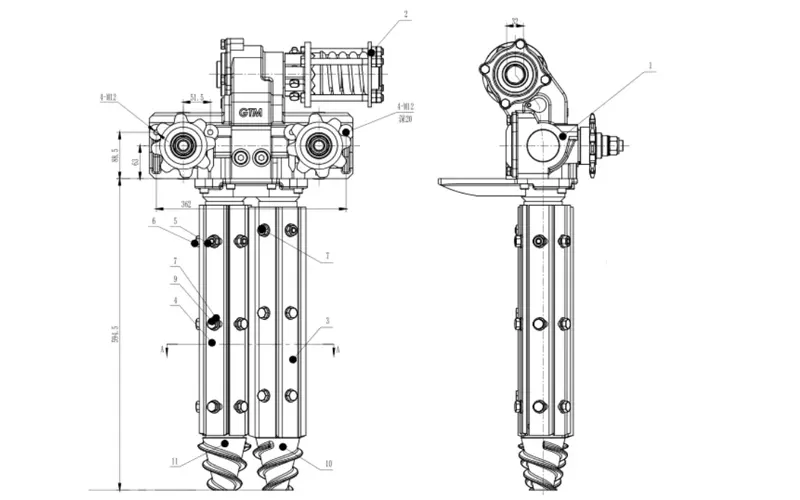

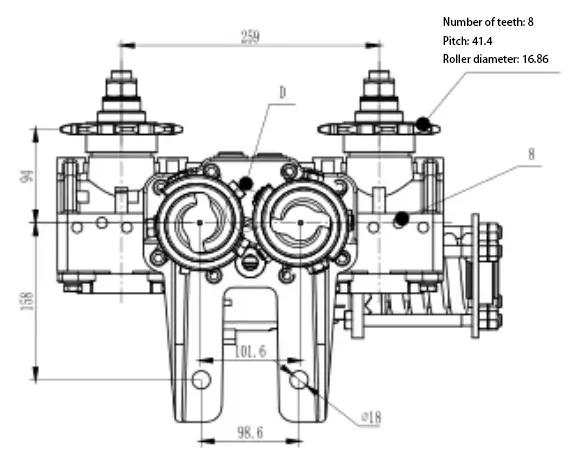

Details of Corn Header Gearbox

| Product name: | Corn header gearbox |

| Gearing Arrangement: | Bevel / Miter |

| Output Torque: | as drawing |

| Input Speed: | 1000rpm |

| Output Speed: | as drawing |

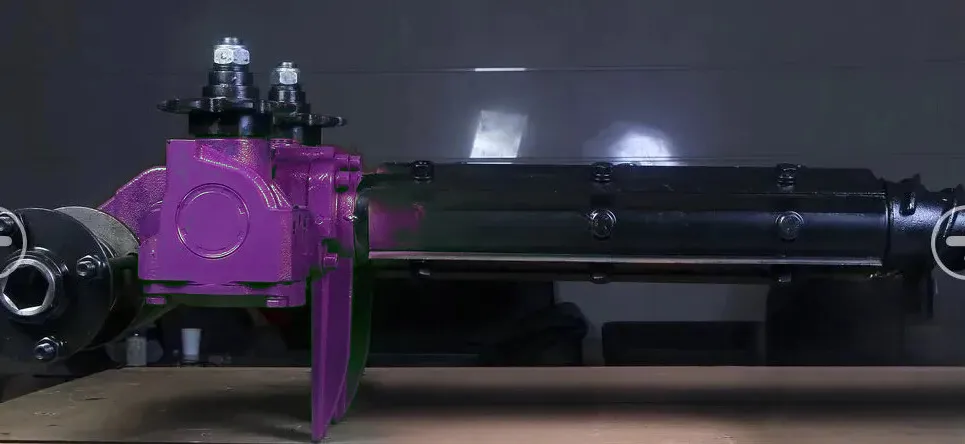

| Color: | Customer Requests |

| Weight: | 82kg |

| Chain wheel ratio: | 1.91:1 |

| Stalk pulled roller ratio: | 1:1.2 |

| Noise: | Less than 92db at 1-meter distance in front of the gearbox |

| Application: | Corn harvester |

| Place of Origin: | Italy |

Specifications of Corn Header Gearbox

The corn header gearbox is a critical component in modern harvesting equipment, responsible for transferring power to various mechanisms of the corn header, such as the gathering chains, augers, and knives. The design and functionality of the gearbox are integral to the efficiency and reliability of the corn harvesting process. Here are the key features of a corn header gearbox:

1. Power Transmission

- The primary function of the corn header gearbox is to transfer mechanical power from the tractor’s PTO shaft to the corn header’s operational components. The gearbox is designed to handle high torque loads, enabling smooth operation of the header’s cutting and gathering mechanisms.

2. High Torque Capacity

- Corn harvesting is a power-intensive task, and the gearbox must be capable of handling high torque forces without failure. Gearboxes for corn headers are specifically engineered to withstand these heavy loads while ensuring efficient power distribution to all necessary parts.

3. Multiple Gear Ratios

- Variable gear ratios are a key feature of the corn header gearbox. These ratios enable operators to adjust the speed and power of the header’s components based on the type of terrain, crop conditions, and operational requirements. The ability to fine-tune these ratios helps optimize performance.

4. Durability and Robust Construction

- Corn header gearboxes are built to endure the harsh environments found in agricultural fields. They are constructed with high-strength materials such as hardened steel and often feature corrosion-resistant coatings. This ensures they maintain durability and operational efficiency even in demanding conditions.

5. Compact and Space-Saving Design

- The gearbox is typically compact and lightweight, allowing for easier integration into the corn header while saving space. This efficient design helps reduce the overall weight of the machine, enhancing its maneuverability and reducing fuel consumption during operation.

In summary, the corn header gearbox is an essential component that enables the smooth, efficient, and reliable operation of the corn header. With its high torque capacity, durability, ease of integration, and low-maintenance design, the gearbox ensures optimal performance during harvesting, reducing downtime and enhancing productivity for farmers.

|

|

About FMP

Headquartered in Italy, FMP is a premier manufacturer known for its expertise in the design, development, and production of high-performance gearboxes, specializing in the agricultural machinery sector. Renowned for precision engineering, innovative solutions, and unwavering reliability, FMP has built a reputation as a trusted partner across both agricultural and industrial markets. Our diverse portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of essential components, all meticulously crafted to meet the unique demands of various applications.

At FMP, we recognize that each client faces distinct challenges. This is why we excel in providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only addresses their specific needs but also optimizes performance and enhances overall value. Our commitment to responsive, professional service and expert guidance ensures that every inquiry is handled with precision, leading to the best possible outcomes.

We place a strong emphasis on transparent, ongoing communication throughout the entire product development process. Our dedicated team works hand-in-hand with clients to fully understand their requirements, providing insightful recommendations to achieve optimal results. Whether we’re developing cutting-edge products or fulfilling routine orders, FMP is dedicated to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to consistently surpass client expectations by providing exceptional service and outstanding results with every project.

At the core of FMP’s operations lies a commitment to quality. We adhere to the highest manufacturing standards and implement rigorous quality control measures to ensure each product not only meets but exceeds industry benchmarks. This dedication to excellence, combined with our core values of integrity, teamwork, and perseverance, has allowed us to build long-term, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to foster global partnerships, offering expert advice and tailored solutions that meet the evolving needs of our clients. We are dedicated to building lasting, mutually beneficial relationships that contribute to the success of every project. Whether you’re seeking innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to help you overcome technical challenges and ensure your continued success.

Author: CX