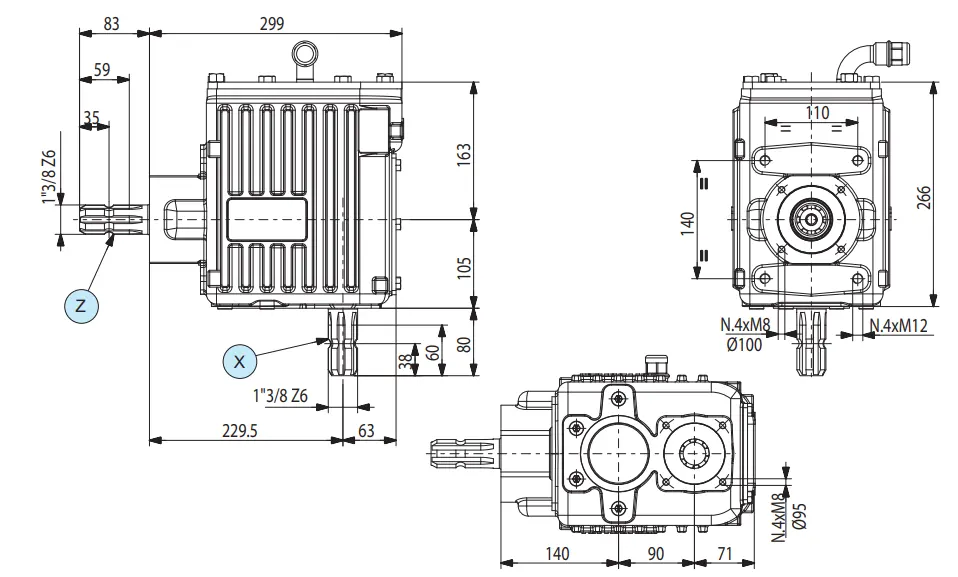

Corn Header Gearbox M-767A Specifications

| i | 1.6 |

| N1[rpm] | 540 |

| P1[kW] | 44.1 |

| M2[Nm] | 473 |

| Shaft Type X | 1” 3/8 Z6 |

| Shaft Type Z | 1” 3/8 Z6 |

| Input | Z |

Maintenance of Corn Header Gearbox

Proper maintenance of the corn header gearbox is essential to ensure the equipment operates efficiently and lasts for many seasons. A well-maintained gearbox improves the performance of the corn header, reduces the likelihood of breakdowns, and extends the overall lifespan of the machine. Below are key maintenance practices for keeping the corn header gearbox in optimal working condition.

1. Regular Lubrication and Oil Changes

- Lubrication: Corn header gearboxes rely on proper lubrication to reduce friction and prevent wear between the internal gears and bearings. Regularly check the oil levels and ensure the gearbox is well-lubricated.

- Check Oil Level: Periodically check the oil level in the gearbox and top it up as necessary.

- Oil Quality: Replace the oil if it becomes contaminated with debris or if it shows signs of degradation. Over time, oil can lose its effectiveness, leading to increased friction and wear.

- Use the Correct Oil: Always use the manufacturer-recommended lubricant to ensure proper performance. The wrong type of oil can cause overheating or failure of components.

- Oil Changes: Follow the manufacturer’s recommended oil change intervals, typically after every 100-200 hours of use. Draining the old oil and replacing it with fresh oil will help maintain proper lubrication and extend gearbox life.

2. Inspect and Maintain PTO Shaft Connection

The PTO (Power Take-Off) shaft is responsible for transmitting power from the tractor to the corn header gearbox. A malfunctioning PTO shaft can cause damage to the gearbox, so it’s crucial to inspect it regularly.

- Check for Wear and Tear: Inspect the PTO shaft for any signs of wear or damage, including cracks, bends, or broken components. Replace any damaged parts immediately.

- Lubricate the PTO Shaft: Grease the PTO shaft regularly to ensure smooth operation and prevent rust or corrosion. Pay attention to the U-joints and sliding sections.

- Proper Alignment: Ensure the PTO shaft is properly aligned with the gearbox input shaft. Misalignment can cause excessive strain on the gearbox and PTO shaft, leading to premature wear.

3. Clean the Gearbox and External Components

Dirt, debris, and crop residues can accumulate on the exterior of the gearbox and surrounding components, leading to overheating or blockage of ventilation areas.

- Clean Gearbox: Regularly clean the gearbox housing to remove any dust, dirt, or crop residues. Use compressed air or a soft brush to clean hard-to-reach areas.

- Check Vents and Cooling Fins: Ensure that any cooling vents and fins are free from blockages to maintain proper airflow. Overheating can lead to gearbox failure.

- Avoid Water Entry: After cleaning, ensure that no water enters the gearbox. Water contamination can cause corrosion and reduce the lubrication efficiency.

4. Monitor Gearbox Temperature

Overheating is a common cause of gearbox failure. Always monitor the temperature of the gearbox during operation, especially in high-load conditions.

- Excessive Heat: If the gearbox becomes unusually hot, it could indicate low oil levels, poor lubrication, or excessive load. Address the issue promptly to prevent damage.

- Cooling Systems: Some corn header gearboxes are equipped with cooling systems. Ensure these are functioning properly, and check for any blockages or leaks in the cooling lines.

5. Check and Tighten Bolts and Fasteners

Gearbox components can loosen over time due to the vibrations and forces experienced during operation. Loose bolts or fasteners can lead to misalignment, excessive wear, or even complete gearbox failure.

- Inspect Bolts: Regularly inspect all the bolts and fasteners on the gearbox, especially around the input and output shafts.

- Tighten as Necessary: Tighten any loose bolts and fasteners to ensure all parts are securely in place. This also helps prevent unnecessary vibrations that can cause damage over time.

Regular maintenance of the corn header gearbox is essential for maximizing its lifespan, performance, and efficiency. By adhering to proper lubrication schedules, performing visual inspections, and addressing any potential issues promptly, you can ensure that your gearbox operates smoothly throughout the harvesting season. Proper care and attention to the gearbox and PTO shaft will also reduce the likelihood of costly repairs and minimize downtime, allowing you to focus on maximizing productivity during harvest.

About FMP

Headquartered in Italy, FMP is a leading manufacturer specializing in the design, development, and production of high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for precision engineering, innovative solutions, and consistent reliability, FMP has built a strong reputation as a trusted partner in both the agricultural and industrial markets. Our comprehensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and other essential components, all designed to meet the specific demands of diverse applications.

At FMP, we understand that each client faces unique challenges. This drives our focus on delivering tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution meets their needs while optimizing performance and maximizing value. Our commitment to timely, professional responses and expert guidance ensures that every inquiry is handled with precision, delivering optimal results.

We prioritize transparent, ongoing communication throughout the entire product development process. Our dedicated team collaborates closely with clients to fully understand their requirements, offering valuable insights and recommendations to achieve the best outcomes. Whether designing innovative products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to exceed client expectations and provide exceptional service with every project.

At the heart of FMP’s operations lies an unwavering commitment to quality. We adhere to the highest manufacturing standards and rigorous quality control processes to ensure that each product exceeds industry benchmarks. This commitment to excellence, combined with our values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is committed to fostering global partnerships by offering expert advice and customized solutions that meet the evolving needs of our clients. We aim to build long-term, mutually beneficial relationships that contribute to the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to help you overcome technical challenges and ensure your continued success.

Author: CX