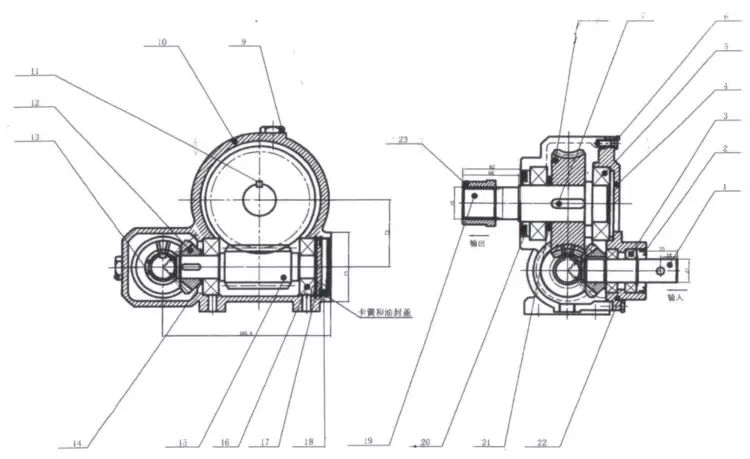

Structure Diagram of 2810 Gearbox

| Component Number | Component Name | Component Number | Component Name | Component Number | Component Name |

|---|---|---|---|---|---|

| 1 | Input Shaft | 2 | Oil Seal | 3 | Deep Groove Ball Bearing |

| 4 | Door Cover | 5 | Deep Groove Ball Bearing | 6 | Hexagonal Head Bolt |

| 7 | Flat Key | 8 | Worm Gear | 9 | Oil Plug Screw |

| 10 | Box | 11 | Flat Key | 12 | Bevel Gear |

| 13 | Circlip | 14 | Shim | 15 | Worm |

| 16 | Deep Groove Ball Bearing | 17 | Circlip | 18 | Oil Seal |

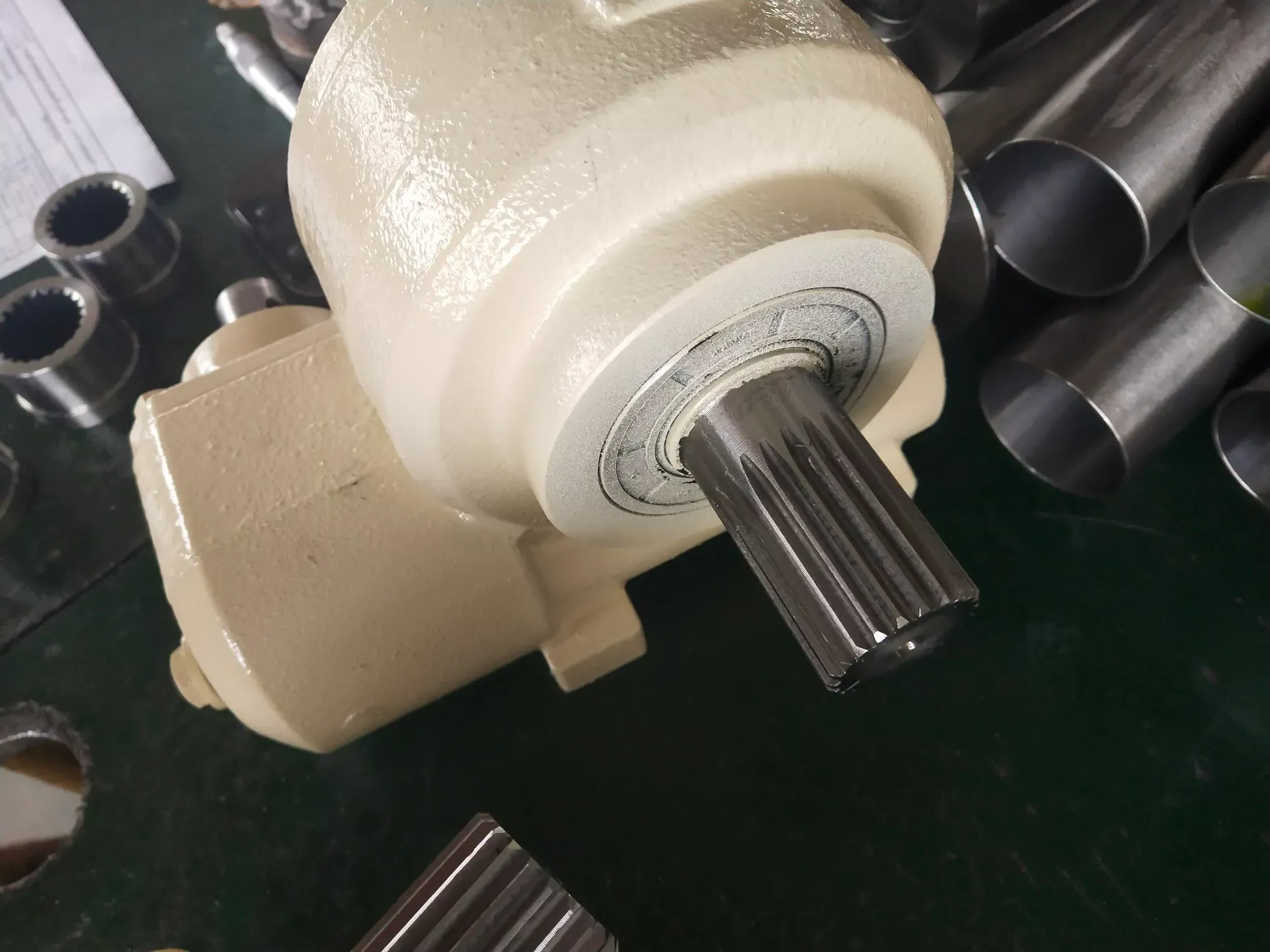

| 19 | Spline Shaft | 20 | Oil Seal | 21 | Retaining Ring |

| 22 | Door Cover | 23 | Spline Sleeve |

Notes:

1. All parts must be cleaned before assembly.

2. During assembly, the bearing must be tightly against the shoulder of the shaft

3. Use WA460 lubricating oil or select the corresponding oil according to the ambient temperature.

4. Conduct a no-load test, and the operation should be flexible and free. After running for 1 hour, the temperature rise should be ≤ 45 ℃

How does the gearbox work in concrete mixer?

The gearbox in a concrete mixer plays a crucial role in transferring power from the motor to the mixing drum, enabling the mixing process. Here’s an overview of how the gearbox works in a concrete mixer:

- Power Transfer: The gearbox is connected to the motor, which provides the power for the mixer’s operation. The motor typically operates at high speed, but the mixing drum requires a slower, controlled speed with higher torque to properly mix the concrete. The gearbox reduces the motor’s high-speed rotation to a slower, more suitable speed for the drum’s rotation.

- Speed Reduction: The gearbox uses a system of gears—often planetary gears or helical gears—to achieve the necessary speed reduction. This ensures that the mixing drum turns at a slower, controlled speed, which is essential for uniform mixing without overworking the motor or damaging the equipment.

- Torque Amplification: Along with reducing speed, the gearbox also amplifies torque, providing the extra force needed to rotate the heavy drum and mix the concrete efficiently. The increased torque ensures that the drum rotates smoothly even when carrying a full load of heavy concrete ingredients.

- Efficient Power Distribution: The gearbox ensures that power is efficiently distributed to the mixing drum and sometimes to other components, such as the augers or paddles, if the mixer has those features. It ensures that the mixing operation is stable, reducing energy loss and maintaining the desired performance.

- Durability and Reliability: The gearbox in a concrete mixer is designed to withstand the heavy, continuous operation in demanding environments. It is made of high-strength materials to handle the stress of frequent start-stop cycles, heavy loads, and exposure to harsh conditions like dust and moisture.

- Maintenance and Longevity: The gearbox is also designed to be easy to maintain, with features like oil lubrication and sealed bearings to ensure smooth operation over time. Regular maintenance ensures that the gearbox continues to operate efficiently, reducing downtime and extending the mixer’s lifespan.

In summary, the gearbox in a concrete mixer is essential for transforming the motor’s high-speed power into low-speed, high-torque motion, ensuring effective and reliable mixing performance. Its role is vital for ensuring uniform mixing, reducing wear and tear on components, and providing the durability needed for long-term use in demanding environments.

|

|

About FMP

FMP is a professional gearbox production factory with a strong reputation for excellence. We are proud to offer a range of core advantages that make us a trusted partner in the gearbox manufacturing industry:

- Excellent Manufacturing Process:

We utilize advanced international production equipment and precision manufacturing technology, ensuring that each gearbox meets the highest industry standards. We strictly adhere to ISO quality management system standards to guarantee precision, strength, and durability. - Diversified Product Line:

Our extensive product line serves a variety of industries, including industrial equipment, agricultural machinery, construction equipment, ship power systems, and new energy transmission systems. We offer both standard and custom solutions tailored to your specific needs, no matter the specifications or requirements. - Innovative R&D Strength:

With a skilled and innovative R&D team, we continuously improve our technology and design to develop new, efficient, energy-saving, low-noise, and high-performance gearboxes. We stay ahead of market trends to meet the latest technological demands. - Selected Raw Materials and Accessories:

We prioritize quality by using high-grade steel and other durable materials. All supporting components, such as bearings and seals, are sourced from reputable domestic and international brands to ensure stable and reliable performance. - Strict Quality Control System:

We maintain rigorous quality checks throughout the production process. From the entry of raw materials to the delivery of finished products, each gearbox undergoes comprehensive testing using advanced equipment to ensure zero defects before shipment. - Full Service Guarantee:

We are committed to providing not only high-quality products but also comprehensive after-sales support. Our services include installation guidance, maintenance, fault diagnosis, and spare parts supply to ensure our customers’ complete satisfaction and peace of mind. - Rich Industry Experience and Good Reputation:

With decades of expertise in gearbox manufacturing, we have gained invaluable experience and a strong technical foundation. Our reputation for quality and reliability has earned the trust of customers worldwide.

Custom Solutions:

At FMP, we are also happy to support custom designs based on your specific needs. If you have a drawing or design in mind, simply email it to us, and our expert team will review it and provide a quotation within 24 hours. We are dedicated to offering fast, efficient, and tailored solutions to help bring your projects to life.