Boom Aerial Work Vehicle Steering Hydraulic Cylinder

The Boom Aerial Work Vehicle Steering Hydraulic Cylinder is a crucial component designed to enhance the maneuverability and control of aerial work platforms. This hydraulic cylinder provides precise steering capabilities, enabling operators to navigate easily in tight spaces and position the lift accurately during various applications.

Key Features:

- Smooth Steering Control: The hydraulic cylinder ensures responsive and smooth steering, allowing for accurate adjustments and superior handling when navigating complex work environments.

- Durable Construction: Made from high-strength materials, this steering hydraulic cylinder is built to withstand the rigors of demanding operational conditions, ensuring long-lasting performance and reliability.

- Efficient Hydraulic System: The advanced hydraulic design maximizes performance while minimizing energy loss, contributing to cost-effective operation and enhanced overall efficiency.

- Safety Enhancements: Equipped with safety features that prevent oversteering and ensure stability, the cylinder helps maintain control during operation, reducing the risk of accidents.

- Versatile Applications: Suitable for various tasks in construction, maintenance, and utility sectors, this steering hydraulic cylinder is essential for maximizing the effectiveness of boom aerial work vehicles.

The Boom Aerial Work Vehicle Steering Hydraulic Cylinder is designed to improve maneuverability, safety, and overall performance, making it an indispensable tool for operators in diverse industries requiring elevated access solutions.

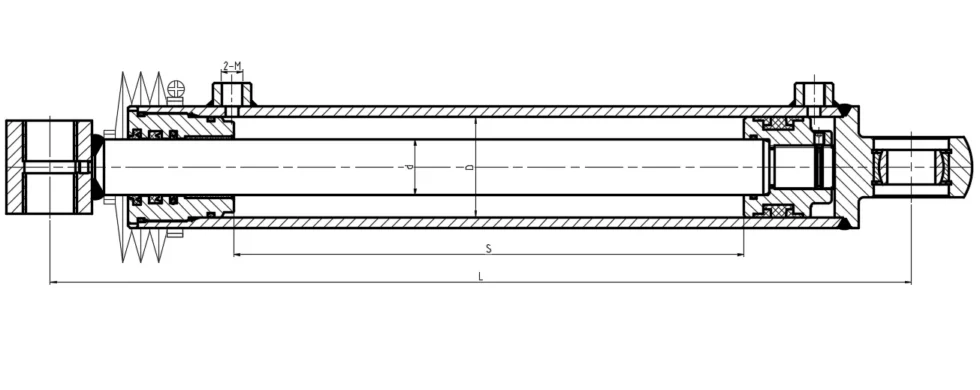

Boom Aerial Work Vehicle Steering Hydraulic Cylinder Dimensions:

|

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Steering cylinder | GTHZ210C-620100-000 | Φ63 | Φ35 | 320 | 540 | 21MPa | 2-M14*1.5 | 13kg |

Boom Aerial Work Vehicle Steering Hydraulic Cylinder Parameter:

| Item | Description |

| Product Name | Steering Hydraulic Cylinder |

| Application | Boom Aerial Work Vehicle |

| Material | 20#/45#, Q345B, 40Cr Steel |

| Acting type | Double Acting Single Acting |

| Core Components | Piston rod, Piston |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | FMP or customer’s logo |

| Service | OEM & ODM |

| Seal brand | Parker, NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Hydraulic Cylinder Available Brand & Models:

| KOMATSU (PC) | PC30,PC40,PC50,PC56,PC60,PC78,PC100,PC110,PC120,PC130,PC160,PC200-3/5/6/7/8/8MO,PC210,PC220-5/6/7/8/8MO,PC240,PC300/350/360-5/6/7/8/8MO,PC400/450-5/6/7/8/8MO,PC800,PC850 |

| CATERPILLAR (E) | E301.5,E302,E305.5,E306,E307V1/V2/B/C/D/E/F,E308B/C,E120B,E312V1/V2/B/C/D,E313D2,E312D2,E315D, E200B,E320V1/V2/A/B/C/D,E324D,E325C/D,E329D,E330/336C/D,E345C,E349D,E365C,E374,E390 |

| KOBELCO (SK) | SK60-3/5/8,SK75-8/SR, SK100 ,SK120-3/5, SK135-8/SR, SK140-8, SK200-3/5/6/6E, SK210-3/5/6/6E, SK230/250-6E,SK250-8,SK260-8,SK350-8/S8,SK460/480-8 |

| HYUNDAI (R) | R55-5/7, R60-5/7, R80, R110,R130, R200-5, R210-5, R215-5/7,R220-5/7/9, R225-5/7/9, R250,R260,R265,R290,R305,R445,R485, R505 |

| HITACHI (EX.ZX) | EX60,EX100-1/2/3,EX120-1/3/5/6,EX200-1/3/5,EX230-5,EX300-1,EX400 ZAX60,ZAX70,ZA120-6,ZAX200/210-1/3/5/5K,ZAX240,ZAX250,ZAX260,ZAX330-3/5/6,ZAX450/470,ZAX650/670,ZAX850/870 |

|

DOOSAN (DH/DX)

|

DH55, DH60, DH80,DH150, DH215-5/7,DH220-5,DH225-5/7,DH258,DH300-5/7, DH370,DH420,DH500

DX55,DX60,DX75,DX130,DX225-9,DX300,DX380,DX420,DX500 |

|

VOLVO (EC)

|

EC55 ,EC60,EC75,EC80,EC140 ,EC210B/D,EC220D,EC240 ,EC250,EC290,EC300, EC360 EC380,EC460,EC480,EC700,EC750,EC950

|

|

KATO (HD)

|

HD307/308,HD450,HD512,HD700-5/7,HD820-1/2/3/5/R,HD1023-1/3,HD1430-1/3

|

|

OTHER BRAND

|

XCMG,LIUGONG,KUBOTA,CASE,YANMAR,SUNWARD,ZOOMLION,LISHIDE,LIEHERR

|

Principle of Boom Aerial Work Vehicle Steering Hydraulic Cylinder

The Boom Aerial Work Vehicle Steering Hydraulic Cylinder operates based on the principles of hydraulics, utilizing fluid pressure to generate movement and force for steering the vehicle. Here’s a breakdown of how it works:

1. Hydraulic Fluid Dynamics

The cylinder contains hydraulic fluid, typically oil, which is used to transmit power. When the operator engages the steering control, a pump directs hydraulic fluid into the cylinder.

2. Piston Movement

Inside the cylinder, a piston is positioned that divides the cylinder into two chambers. As hydraulic fluid enters one chamber, it pushes the piston, causing it to move. This movement translates into the steering action of the vehicle.

3. Fluid Pressure Regulation

The amount of hydraulic fluid and its pressure are regulated to control the speed and force of the piston movement. By adjusting the flow of fluid, the operator can achieve precise steering responses, allowing for smooth and accurate maneuvering.

4. Return Mechanism

Once the desired steering angle is achieved, the hydraulic fluid is redirected back to the reservoir, allowing the piston to return to its original position. This return action is essential for resetting the steering mechanism and preparing for the next maneuver.

5. Safety Features

Many steering hydraulic cylinders include safety mechanisms, such as pressure relief valves, which prevent overloading and ensure stable operation. These features help maintain control and prevent accidents while operating the vehicle.

The steering hydraulic cylinder’s efficient use of hydraulic principles allows for precise control and maneuverability of boom aerial work vehicles. By converting hydraulic pressure into linear motion, it enables operators to navigate complex environments safely and effectively, making it an essential component in aerial work applications.

About FMP

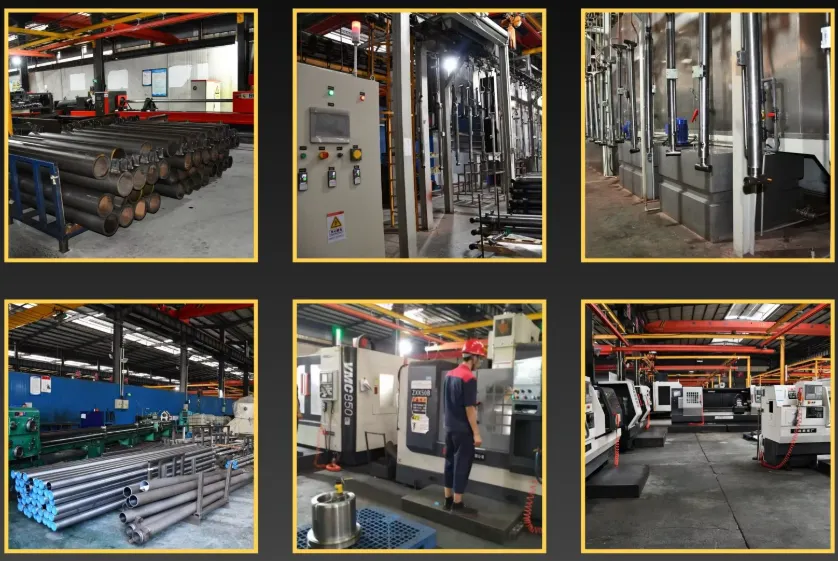

FMP is a specialized manufacturer of hydraulic cylinders, renowned for its strong emphasis on research and production excellence. Since its inception, the company has dedicated itself to the continuous development of hydraulic cylinder technology. Initially, FMP produced a diverse range of products for harvesting and construction machinery; however, it has since honed its focus specifically on components for agricultural tractors.

With over a decade of manufacturing expertise, FMP combines extensive management experience with advanced production technologies to ensure the highest quality standards in its products. The company has established a comprehensive machining production line, assembly line, and coating line, enabling it to deliver reliable and efficient manufacturing processes.

FMP’s growth has been supported by a dedicated team comprising experienced management personnel, skilled mechanical designers, and highly trained technicians. This collaborative approach ensures consistent product quality and effectively manages process continuity, enhancing overall production efficiency.

At the core of FMP’s philosophy are the values of “Technological Innovation Driving Progress,” “Quality Creating Brands,” “Craftsmanship Ensuring Quality,” and “Building Long-Term Win-Win Relationships.” The company is committed to providing high-quality products while delivering exceptional customer service. FMP continuously strives to adapt to the evolving needs of the market, positioning itself as a trusted partner in the agricultural machinery industry. Through its dedication to innovation and quality, FMP aims to contribute significantly to the advancement of hydraulic technology in the agricultural sector.

Author: CX