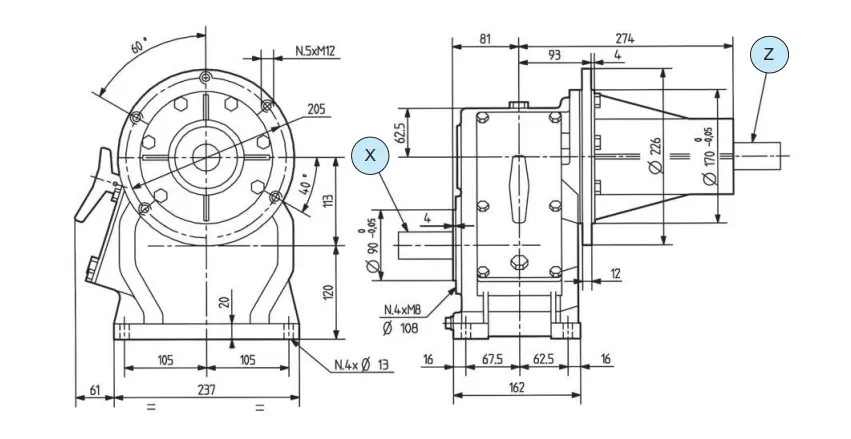

Specifications of Agricultural Sprayer Gearbox D21B/D21F

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X |

Z |

|||||

| 3.90 4.90 |

540 | 38.9 | – | 1” 3/8 Z6 | L270 35 | X |

| 3.60 4.50 |

540 | 40.5 | – | 1” 3/8 Z6 | L165 40 | X |

| 3.60 4.50 |

540 | 47.8 | – | 1” 3/8 Z6 | L286 40 | X |

| 2.90 3.90 |

540 | 41.2 | – | 1” 3/8 Z6 | L221 35 | X |

Key Components of Agricultural Sprayer Gearbox

The key components of an agricultural sprayer gearbox are critical for its function, durability, and efficiency in spraying operations. These components ensure the smooth transmission of power and facilitate optimal performance in agricultural tasks. The main components typically include:

- Input Shaft: The input shaft connects the gearbox to the power source, usually a tractor’s PTO (Power Take-Off). It transmits rotational power from the tractor to the gearbox, enabling the gearbox to operate.

- Gear Set (Helical or Spur Gears): The gear set is essential for transmitting rotational power from the input shaft to the output shaft. The gears are designed to provide the necessary speed and torque adjustments required for the sprayer’s pump or other associated mechanisms.

- Output Shaft: The output shaft transmits power to the sprayer components, such as the pump or spray arms. It is connected to the parts that control the application of the spray, driving them in a coordinated manner.

- Bearings and Seals: Bearings are used to reduce friction between moving parts, ensuring smooth rotation and preventing wear. Seals are critical for preventing oil leakage, contamination, and the entry of moisture, thereby extending the life of the gearbox.

- Housing: The gearbox housing encloses all internal components and provides structural integrity. It is designed to withstand high pressures, environmental conditions, and the mechanical stresses generated during operation.

- Lubrication System: The lubrication system ensures that the moving parts within the gearbox operate smoothly, reducing friction and preventing overheating. Proper lubrication is essential for extending the lifespan and efficiency of the gearbox.

- Overload Protection: Some agricultural sprayer gearboxes are equipped with overload protection features, such as shear pins or clutch mechanisms, to prevent damage to the gearbox in the event of unexpected resistance or operational stress.

These key components work together to ensure the gearbox efficiently transfers power, manages speed and torque, and supports the sprayer’s functionality. Regular maintenance and inspection of these components are crucial for optimal performance and durability.

Agricultural Applications of the Sprayer Gearbox

Agricultural sprayer gearboxes play a crucial role in various agricultural applications by ensuring efficient and precise spraying of fertilizers, pesticides, herbicides, and other chemicals. Here are some key agricultural applications where sprayer gearboxes are widely used:

- Crop Protection: Sprayer gearboxes are integral to the operation of sprayers used for crop protection. They enable the efficient application of pesticides, herbicides, fungicides, and insecticides. These gearboxes help maintain consistent pressure and flow, ensuring that the chemicals are evenly distributed across large fields, protecting crops from pests and diseases.

- Fertilization: Gearboxes in fertilizer spreader sprayers help control the flow and distribution of liquid fertilizers over farmland. They ensure that fertilizers are applied uniformly, which is essential for promoting healthy crop growth and optimizing yield. These systems are designed to handle various types of liquid fertilizers, providing precise application across different soil conditions.

- Weed Control: Agricultural sprayer gearboxes are used in sprayers designed for weed management. By delivering herbicides efficiently, these gearboxes enable the targeted control of weeds, reducing competition for nutrients and water in crops. This application is essential for improving crop productivity and reducing the need for manual labor.

- Post-Harvest Applications: Sprayer gearboxes are also employed in post-harvest treatments for crops. After harvest, sprayers may be used to apply protective coatings or preservatives to fruits, vegetables, and grains, enhancing their shelf life and preventing spoilage during transportation and storage.

- Field Irrigation and Chemical Mixing: Some sprayer gearboxes are part of irrigation systems, where they help mix and distribute chemicals such as growth regulators or fungicides along with water. These gearboxes ensure a uniform and controlled distribution of the solution over the crops, ensuring optimal growth conditions.

- Orchard and Vineyard Spraying: In specialized applications like orchards and vineyards, sprayer gearboxes are essential for applying treatments that protect crops from pests, diseases, and environmental stress. The gearboxes provide consistent power to the sprayer, ensuring accurate coverage of plants and trees in rows and varying terrains.

- Soil Treatment: In certain agricultural systems, sprayer gearboxes are used for soil treatment purposes, such as applying soil conditioners or pre-planting chemicals. These gearboxes ensure precise and even distribution of soil treatments, improving soil health and supporting better crop yields.

These diverse agricultural applications demonstrate the critical role of sprayer gearboxes in ensuring effective and efficient spraying processes. By delivering consistent power, accurate control, and reliable performance, sprayer gearboxes contribute to higher crop yields, improved pest and disease management, and better overall farm productivity.

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unwavering reliability, FMP has established itself as a trusted partner in meeting the evolving demands of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all designed to provide effective, customized solutions across a wide range of applications.

At FMP, we understand that every client has unique needs and challenges. This is why we specialize in offering tailored solutions, whether through individual components or fully integrated systems. We take a collaborative approach, working closely with our customers to ensure that each solution is not only effective but also efficient. Our commitment to fast, professional responses and expert guidance guarantees that every inquiry is handled with the utmost care and precision, ensuring the best outcomes for our clients.

We place a strong emphasis on open and ongoing communication, particularly in the development of new products. Our dedicated team works directly with clients to fully understand their requirements, offering valuable insights and recommendations that lead to optimal solutions. Whether we are designing innovative products or fulfilling existing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time, ensuring that our clients receive the best service and results.

At the core of FMP’s operations is our relentless focus on quality. We adhere to the highest manufacturing standards, employing stringent quality control measures to ensure that every product not only meets but exceeds industry expectations. This commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trusting relationships with customers in nearly 30 countries around the world.

FMP is always eager to build global partnerships and remains dedicated to providing expert guidance and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely delivering products; we aim to cultivate long-term relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and help ensure your sustained success.

Author: CX