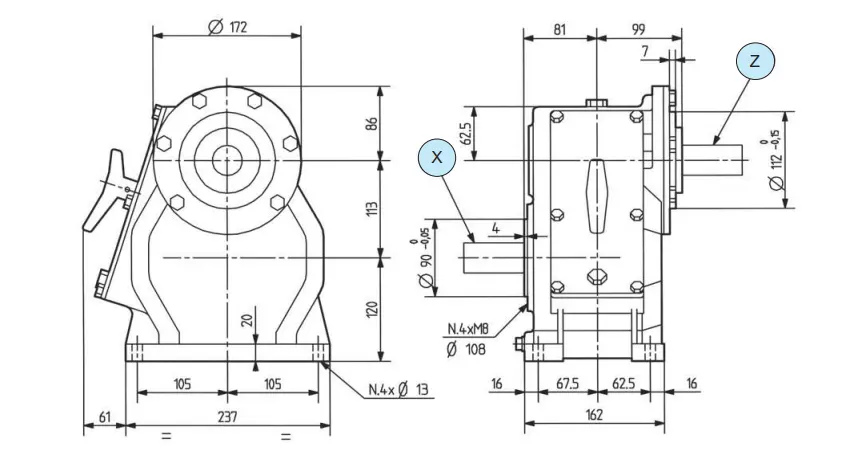

Specifications of Agricultural Sprayer Gearbox D21A

D21A

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X |

Z |

|||||

| 6.95 7.45 |

540 | 26.5 | – | 1” 3/8 Z6 | L108 35 | X |

| 3.90 4.90 |

540 | 40.5 | – | 1” 3/8 Z6 | L271.5 30 | X |

| 3.60 4.50 |

540 | 40.5 | – | 1” 3/8 Z6 | L273 40 | X |

| 3.60 4.50 |

540 | 40.5 | – | 1” 3/8 Z6 | L270 35 | X |

| 3.60 4.50 |

540 | 47.8 | – | 1” 3/8 Z6 | L100 35 | X |

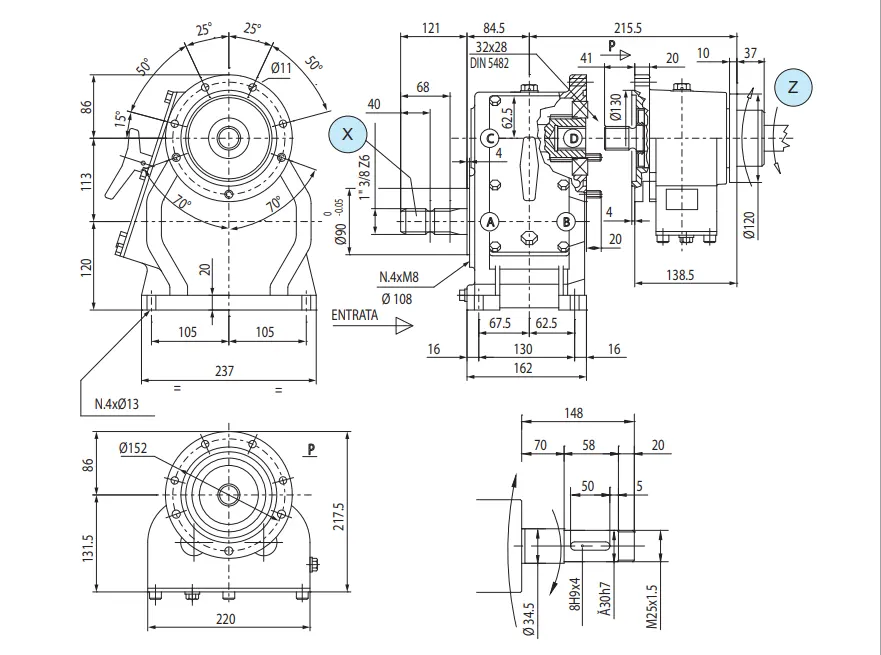

D21A Double Output

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X |

Z |

|||||

| 3.60 4.93 |

540 | 40.5 | – | 1” 3/8 Z6 | L360 35 Φ30 |

X |

Characteristics of Agricultural Sprayer Gearbox

- Durability and Robust Construction

Agricultural sprayer gearboxes are designed to withstand the demanding conditions of agricultural environments. These gearboxes are constructed from high-strength materials such as alloy steel, ensuring they can endure heavy-duty use and resist wear and tear from exposure to dirt, moisture, and vibrations. This robustness ensures that the gearbox operates reliably over an extended period, even under tough working conditions, which is crucial for agricultural applications where equipment often operates in challenging environments. - High Power Transmission Efficiency

Agricultural sprayer gearboxes are engineered to efficiently transmit the mechanical power from the tractor’s PTO system to the sprayer pump. The gearbox converts the rotational energy supplied by the tractor’s engine into the required power for the sprayer’s various components, ensuring smooth and uniform spraying of chemicals or fertilizers. This efficient power transmission is essential for optimal spray pressure, flow rates, and overall performance, making the gearbox a critical component in maximizing productivity. - Compact and Space-Efficient Design

Agricultural sprayer gearboxes are often designed to be compact and space-efficient, allowing them to be easily mounted on various sprayer systems without taking up excessive space. This design characteristic is particularly important for maintaining the balance and maneuverability of the sprayer. A compact gearbox ensures that it does not interfere with other sprayer components, such as the tank or spray nozzles, while also keeping the system lightweight and easy to handle. - Versatility and Adaptability

These gearboxes are highly adaptable and can be used with a wide range of agricultural sprayers, including both small and large-scale models. Whether used on tractor-mounted sprayers or self-propelled units, agricultural sprayer gearboxes are designed for versatility and can handle varying power requirements. Their compatibility with different sprayer configurations and operating conditions makes them a reliable solution for diverse agricultural operations, from crop protection to fertilization. - Easy Maintenance and Longevity

Agricultural sprayer gearboxes are designed with ease of maintenance in mind. They often feature user-friendly designs that allow easy access to internal components for lubrication and inspection. Routine maintenance, such as checking oil levels, applying grease, and replacing seals or filters, is simple and can extend the life of the gearbox. The longevity of the gearbox is enhanced by its durable design, ensuring consistent performance over multiple growing seasons, which is a critical factor for farmers who rely on equipment that performs reliably year after year. - Built-in Safety Features

Many agricultural sprayer gearboxes are equipped with safety features that protect both the gearbox and connected components. These features may include overload protection systems such as shear pins or clutches, which prevent damage to the gearbox in the event of sudden mechanical stress or obstruction. When excessive force is detected, these safety mechanisms disengage or limit power transmission, preventing breakdowns and reducing the risk of costly repairs or downtime.

Agricultural sprayer gearboxes are characterized by their durability, power transmission efficiency, compact design, and ease of maintenance. These features make them essential for reliable, long-lasting performance in demanding agricultural environments. With their versatility, built-in safety mechanisms, and consistent operation, agricultural sprayer gearboxes play a pivotal role in ensuring efficient and effective spraying systems for a wide range of agricultural applications.

Applications for the Agricultural Sprayer Gearbox

- Tractor-Mounted Sprayers

Agricultural sprayer gearboxes are widely used in tractor-mounted sprayers, where they are responsible for transferring power from the tractor’s PTO system to the sprayer pump. These gearboxes enable the sprayer to distribute fertilizers, pesticides, and herbicides evenly across crops. Tractor-mounted sprayers are used for a variety of applications, from large-scale commercial farming to smaller orchards or vineyards, making the gearbox essential for ensuring consistent spray patterns and efficient chemical application. - Self-Propelled Sprayers

In self-propelled sprayers, the gearbox plays a crucial role in powering the sprayer system independently of a tractor. These sprayers are commonly used for large-acreage applications and are equipped with their own engines and transmission systems. The gearbox in self-propelled sprayers helps control the sprayer’s pump speed, ensuring accurate and efficient chemical distribution. It also facilitates easy adjustments to spraying rates, providing flexibility for different crop types and field conditions. - Boom Sprayers

Agricultural sprayer gearboxes are integral to boom sprayers, which are used to apply liquids across large swaths of land, such as fields of cereals, vegetables, or other crops. The gearbox is responsible for driving the pumps that power the spray nozzles on the boom. It ensures that the spraying is uniform and that the liquid is delivered with precise control over the area being sprayed. These systems are often used in precision agriculture, where consistent application is critical to minimizing waste and optimizing crop protection. - Fertilizer Spreader Units

Many fertilizer spreaders are integrated with sprayer systems for dual applications, such as simultaneous fertilizing and spraying. The gearbox in these systems is responsible for providing the power needed to operate the spreader’s rotating mechanisms while ensuring the sprayer is functioning properly. This application is especially useful in fields where both fertilizer and crop protection products need to be applied together in one operation, streamlining the process and reducing equipment passes. - Field Crop Protection

Sprayer gearboxes are commonly used in field crop protection, where they power sprayers used to apply pesticides and herbicides to large fields of crops such as grains, corn, and soybeans. The gearbox ensures that the spraying system is operating at the correct pressure and flow rate, which is crucial for effective pest control and weed management. By ensuring uniform application, the gearbox helps reduce the overuse of chemicals, improving environmental sustainability and reducing input costs for farmers. - Orchard and Vineyard Spraying

In orchards and vineyards, sprayer gearboxes are used in specialized sprayers designed to navigate tight rows of trees or vines. These sprayers often use smaller, more compact gearboxes tailored to the unique needs of fruit tree cultivation. The gearbox is responsible for driving the spray pumps that distribute water, fertilizers, or pesticides. By providing consistent spray pressure, the gearbox helps ensure that these delicate crops receive optimal treatment without damaging the plants.

Agricultural sprayer gearboxes play a vital role in various applications, from large-scale field crop protection to specialized sprayers in orchards and greenhouses. Their primary function is to efficiently transmit power from the tractor or self-propelled unit to the sprayer pump, ensuring consistent and precise application of chemicals. Whether for pesticides, fertilizers, or herbicides, the gearbox ensures that spraying systems operate effectively across a wide range of agricultural operations, contributing to improved crop management, sustainability, and productivity.

About FMP

Based in Italy, FMP is a leading manufacturer specializing in the design, development, and production of high-performance gearboxes, primarily for the agricultural machinery sector. Known for precision engineering, innovation, and reliability, FMP has built a strong reputation for delivering superior products that meet the evolving needs of both agricultural and industrial markets. Our extensive product range includes specialized gearboxes for lawn mowers, PTO shafts, and other key components, all designed to provide customized solutions across a variety of applications.

We understand that every client has unique requirements, which is why we offer tailored solutions, whether through individual components or complete integrated systems. By working closely with our customers, we ensure that every solution is both effective and efficient. Our commitment to prompt, professional responses and expert guidance ensures that every inquiry is handled with care and precision, delivering optimal results.

Open communication is a cornerstone of our approach, particularly in product development. Our team works directly with clients to fully understand their needs, providing valuable insights that lead to the best solutions. Whether designing innovative products or fulfilling orders, FMP is dedicated to delivering high-quality, precision-engineered solutions on time, every time.

Quality is at the heart of FMP’s operations. We adhere to the highest manufacturing standards and implement rigorous quality control measures to ensure that every product exceeds industry expectations. This focus on quality, combined with our core values of integrity, teamwork, and perseverance, has helped us establish long-lasting relationships with customers in nearly 30 countries worldwide.

FMP is committed to building global partnerships, offering expert advice and tailored solutions to meet diverse client needs. We go beyond product delivery, aiming to build enduring relationships that drive the success of every project. Whether seeking innovative solutions for a new venture or ongoing support for an existing system, FMP is dedicated to addressing your technical challenges and ensuring your continued success.

Author: CX