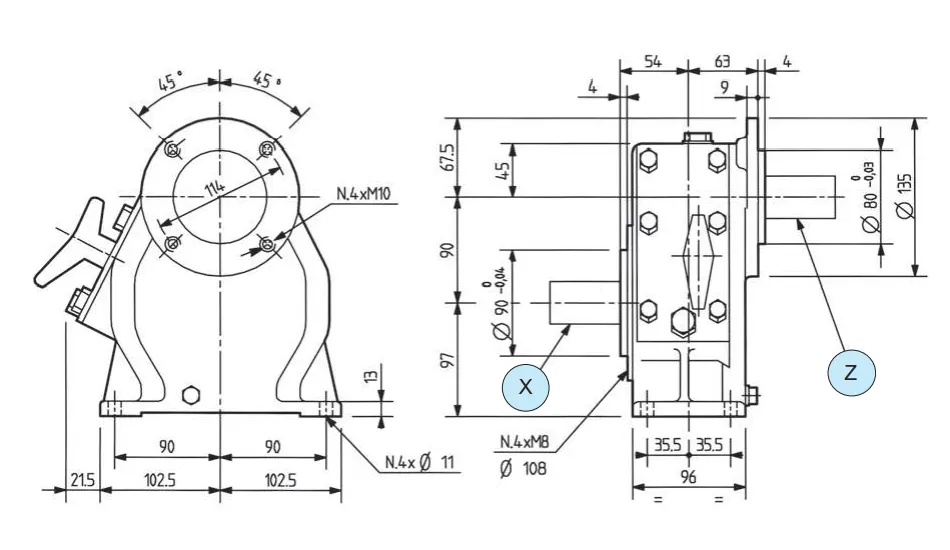

Specifications of Agricultural Sprayer Gearbox D-7A & D-7B

D-7A

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X

|

Z

|

|||||

| 5.82 | 540 | 16.2 | 48 | 1” 3/8 Z6 | 35 | X |

| 4.36 | 540 | 21.3 | 84 | 1” 3/8 Z6 | X | |

| 4.00 | 540 | 21.7 | 93 | 1” 3/8 Z6 | X | |

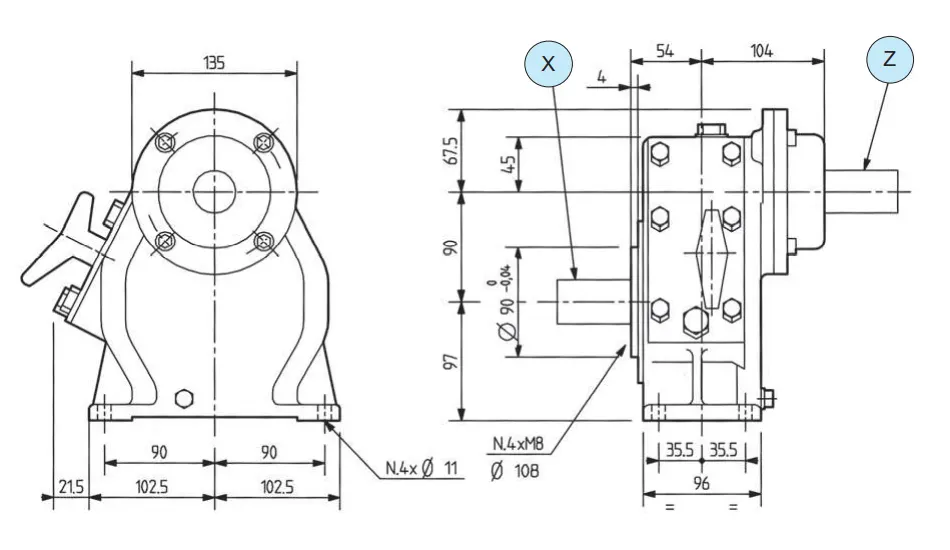

D-7B

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X

|

Z

|

|||||

| 5.25 | 540 | 20.6 | 67 | 1” 3/8 Z6 | X | |

| 4.36 | 540 | 21.3 | 83 | 1” 3/8 Z6 | X | |

| 4.00 | 540 | 21.7 | 95 | 1” 3/8 Z6 | 40 | X |

Agricultural Sprayer Gearbox Features

- High Efficiency Power Transmission

Agricultural sprayer gearboxes are designed to efficiently transmit power from the tractor’s PTO (Power Take-Off) system to the sprayer’s pump or spraying mechanism. These gearboxes ensure smooth and reliable operation, allowing the sprayer to deliver consistent fluid flow and spraying coverage, which is crucial for effective crop protection and nutrient application. - Durability and Robust Construction

Built to endure the harsh conditions of agricultural environments, agricultural sprayer gearboxes are made from high-quality, durable materials like hardened steel and cast iron. These materials are designed to resist wear and tear, even under heavy loads and extended use, ensuring long service life and minimizing downtime for maintenance. - Corrosion Resistance

Given the exposure to chemicals and weather elements, agricultural sprayer gearboxes are designed with corrosion-resistant coatings and seals. This prevents the gearbox from being damaged by the spraying chemicals, moisture, and soil, extending the gearbox’s lifespan and maintaining optimal performance in challenging environments. - Compact and Lightweight Design

Agricultural sprayer gearboxes are engineered with a compact and lightweight design, making them easy to integrate into sprayer systems without adding significant weight. This feature improves the overall maneuverability and efficiency of the sprayer, ensuring that the system can be operated with minimal strain on the tractor. - Adjustable Speed and Flow Control

Many agricultural sprayer gearboxes are equipped with adjustable gears, allowing operators to control the speed and flow rate of the sprayer’s pump. This flexibility ensures that the sprayer can be fine-tuned to meet specific crop or field requirements, enabling precise application of fertilizers, pesticides, and herbicides for optimal crop protection and growth. - Low Maintenance Requirements

Agricultural sprayer gearboxes are designed with ease of maintenance in mind. With features like sealed bearings and well-protected gears, these gearboxes require minimal maintenance. Regular inspection and lubrication are usually sufficient to keep the gearbox running smoothly, making them cost-effective for farmers in the long term. - High Torque Capacity

Agricultural sprayer gearboxes are designed to handle high torque, ensuring that the power generated by the tractor’s PTO is effectively transmitted to the sprayer system without compromising performance. This high torque capacity ensures that the sprayer can maintain consistent operation even in challenging field conditions or when working with large-scale equipment.

Agricultural sprayer gearboxes are essential components for efficient and reliable spraying operations. Their durability, corrosion resistance, adjustable controls, and compact design make them ideal for meeting the demanding needs of modern agriculture, contributing to successful crop management and protection.

Key Components of the Agricultural Sprayer Gearbox

- Input Shaft

The input shaft is the primary connection point where the power is transferred from the tractor’s PTO (Power Take-Off) system to the gearbox. This component is designed to handle high torque from the PTO, ensuring that it can withstand the force required to drive the sprayer’s pump or spraying system. The input shaft is typically constructed from high-strength materials to ensure durability and long-lasting performance. - Gears and Gear Train

The gear system is the heart of the agricultural sprayer gearbox. It consists of multiple gears, including bevel gears, spur gears, and planetary gears, depending on the design. These gears work together to transmit power efficiently, converting the high-speed rotation of the PTO into the appropriate speed and torque needed for the sprayer. The gear system is typically made from hardened steel for improved strength and wear resistance. - Bearings

Bearings are crucial components that reduce friction and support the rotating parts of the gearbox. In agricultural sprayer gearboxes, bearings are typically sealed or lubricated for durability and protection against harsh conditions. High-quality bearings ensure smooth operation, reducing the risk of overheating and wear while increasing the overall efficiency and lifespan of the gearbox. - Output Shaft

The output shaft is connected to the sprayer’s pump or spraying mechanism, transmitting the power from the gearbox to operate the sprayer’s pump. The output shaft’s design ensures that it can handle the torque and speed requirements of the sprayer system. It is typically designed with high torque capacity and is made of robust materials to ensure reliability under demanding agricultural conditions. - Seals and Gaskets

Seals and gaskets are critical for preventing leakage of lubricant and protecting the internal components of the gearbox from dirt, water, and chemicals. Agricultural sprayer gearboxes are exposed to harsh conditions, including wet fields and spraying chemicals, so high-quality seals are essential for ensuring that the gearbox operates efficiently and is protected from external contaminants. - Housing

The gearbox housing is the outer casing that holds and protects all of the internal components. It is usually made of cast iron or durable aluminum alloys to provide strength and resistance against wear and impact. The housing ensures that all components stay in place and provides a durable shell that can withstand external environmental factors such as moisture, chemical exposure, and rough handling. - Lubrication System

The lubrication system includes the oil sump and channels that distribute lubricant to the moving parts of the gearbox. Proper lubrication is essential to reduce friction, prevent overheating, and extend the gearbox’s service life. The system ensures that the gears, bearings, and other moving components are adequately lubricated to maintain smooth and efficient operation under heavy loads.

In summary, the key components of an agricultural sprayer gearbox work together to ensure efficient and reliable power transmission from the tractor’s PTO to the sprayer’s operational systems. With durable gears, high-strength shafts, effective sealing, and proper lubrication, these components are designed to endure the harsh conditions of agricultural environments, ensuring that sprayers perform optimally over extended periods.

Working Principle of the Agricultural Sprayer Gearbox

- Power Transfer from PTO

The agricultural sprayer gearbox operates by receiving power from the tractor’s PTO (Power Take-Off) system. The PTO shaft, typically located at the rear of the tractor, delivers mechanical energy that is transferred to the input shaft of the gearbox. This input shaft is designed to handle the high torque produced by the tractor’s engine, ensuring the power is directed into the gearbox without excessive strain on the components. - Speed Reduction and Torque Conversion

Inside the gearbox, the power from the PTO is subjected to a series of gears designed to reduce the rotational speed. Gear configurations such as spur gears, bevel gears, or planetary gears are used to convert the high-speed, low-torque input from the tractor into a lower-speed, higher-torque output that is ideal for the sprayer. This speed reduction is essential because agricultural sprayers require controlled, consistent power to operate their pumps and spraying mechanisms effectively. - Power Transmission to the Sprayer Pump

The reduced speed and increased torque are transferred via the output shaft of the gearbox to the sprayer’s pump or spraying mechanism. The output shaft connects directly to the pump or other spraying systems, ensuring that the power generated by the tractor is efficiently utilized for spraying liquids such as pesticides, herbicides, or fertilizers. The gearbox ensures that the sprayer pump operates at the correct speed, providing the necessary flow rate and pressure for effective spraying. - Lubrication and Cooling

As the gearbox operates, the gears and other internal components generate friction and heat. To ensure smooth and efficient operation, the gearbox is equipped with a lubrication system that distributes oil or grease to all moving parts. This system reduces friction, prevents overheating, and extends the lifespan of the gearbox. Proper lubrication is critical in maintaining the efficiency of the gearbox, especially under the demanding conditions of agricultural work. - Overload Protection and Safety

To protect the gearbox from sudden mechanical overloads, many agricultural sprayer gearboxes are equipped with an overload protection mechanism, such as a shear pin or a clutch system. This system is designed to absorb excessive strain, preventing damage to the internal gears and shafts in case of an obstruction or sudden change in load. If an overload occurs, the protection mechanism engages, allowing the gearbox to continue functioning without suffering permanent damage.

In summary, the agricultural sprayer gearbox works by transferring power from the tractor’s PTO to the sprayer’s pump or spraying mechanism. It reduces the speed of the incoming power, converts it into higher torque, and ensures the sprayer operates at optimal speed and efficiency. The gearbox is also equipped with lubrication systems to reduce wear and prevent overheating, and overload protection mechanisms to ensure safe and reliable operation.

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unwavering reliability, FMP has established itself as a trusted partner in meeting the evolving demands of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all designed to provide effective, customized solutions across a wide range of applications.

At FMP, we understand that every client has unique needs and challenges. This is why we specialize in offering tailored solutions, whether through individual components or fully integrated systems. We take a collaborative approach, working closely with our customers to ensure that each solution is not only effective but also efficient. Our commitment to fast, professional responses and expert guidance guarantees that every inquiry is handled with the utmost care and precision, ensuring the best outcomes for our clients.

We place a strong emphasis on open and ongoing communication, particularly in the development of new products. Our dedicated team works directly with clients to fully understand their requirements, offering valuable insights and recommendations that lead to optimal solutions. Whether we are designing innovative products or fulfilling existing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time, ensuring that our clients receive the best service and results.

At the core of FMP’s operations is our relentless focus on quality. We adhere to the highest manufacturing standards, employing stringent quality control measures to ensure that every product not only meets but exceeds industry expectations. This commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trusting relationships with customers in nearly 30 countries around the world.

FMP is always eager to build global partnerships and remains dedicated to providing expert guidance and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely delivering products; we aim to cultivate long-term relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and help ensure your sustained success.

Author: CX