Product Specifications:

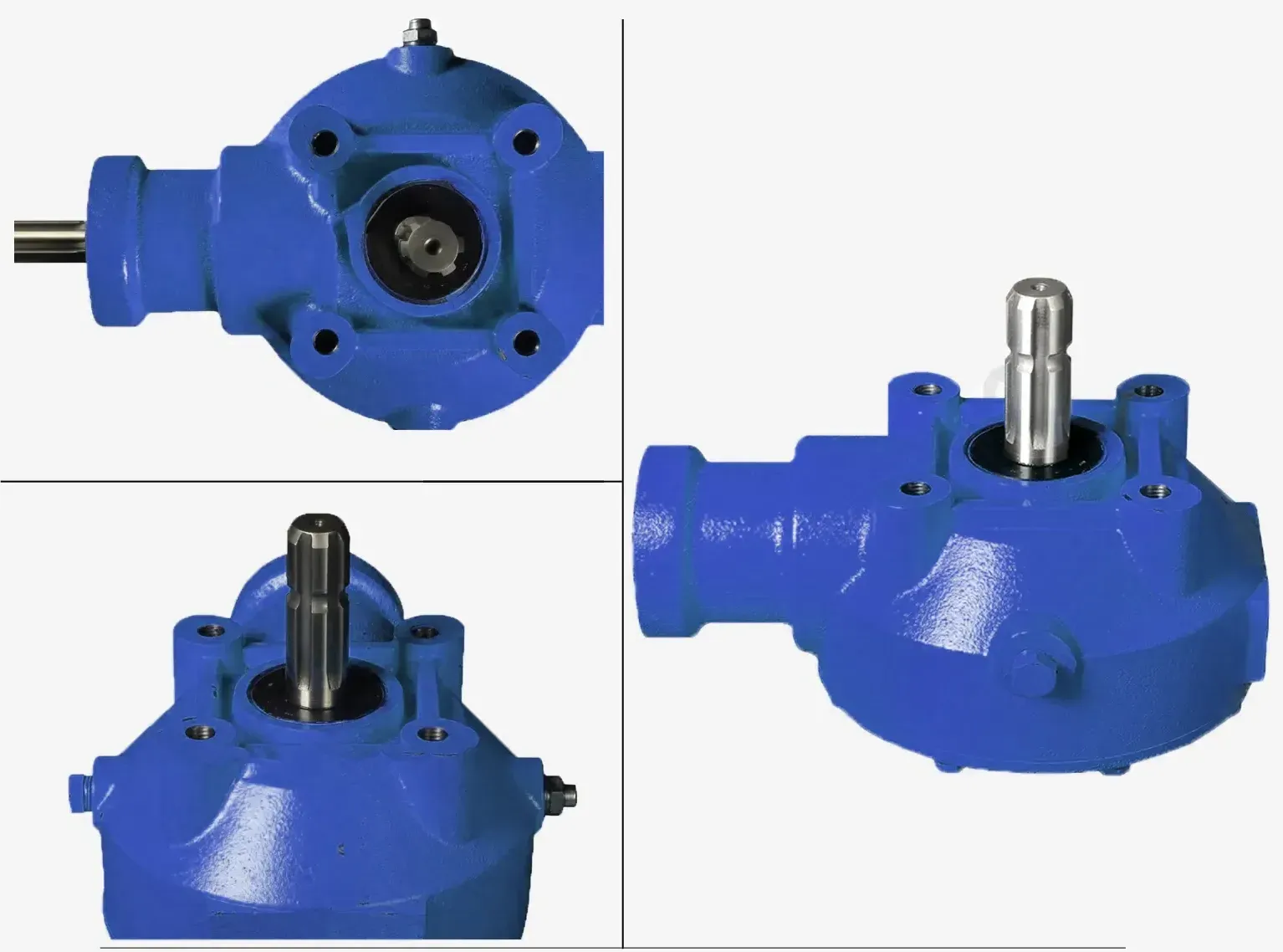

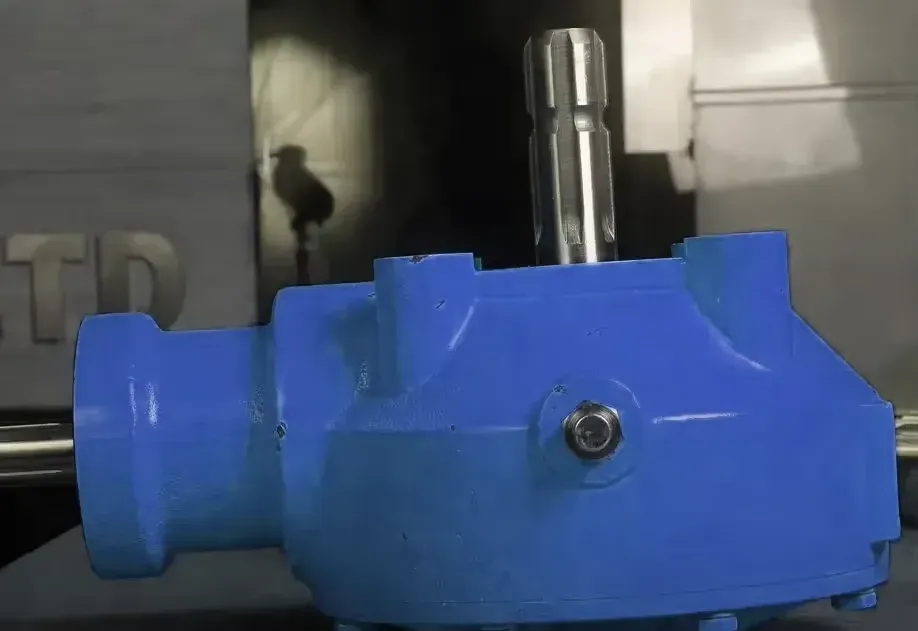

| Product Name | Potato Harvester Gearbox |

| Material | Iron |

| Type | FMP-LLTC-14 |

| Color | Customization |

| Rated Power | 15KW |

| Ratio | 1:3.92 |

| Warranty | One and half year |

| Used | Potato harvester |

Advantages of Potato Harvester Gearbox

The potato harvester gearbox is a vital component in modern agricultural machinery, providing several benefits that enhance the performance, efficiency, and durability of potato harvesting operations. Below are some of the key advantages of using a potato harvester gearbox:

1. Optimized Power Transmission

- Potato harvester gearboxes are designed to efficiently transfer power from the tractor’s PTO (Power Take-Off) to the various components of the harvester. This ensures smooth operation and consistent performance, especially when handling heavy loads in challenging field conditions.

2. Enhanced Durability

- Built to withstand harsh agricultural environments, potato harvester gearboxes are engineered for high durability. The use of high-strength materials and precision manufacturing ensures that they can handle the stress and strain of continuous operation in the field, reducing the risk of breakdowns and increasing the machine’s lifespan.

3. Precision and Efficiency

- The gearbox in a potato harvester is designed to provide precise control over the various mechanisms involved in harvesting, such as the digging, separating, and conveying of potatoes. By optimizing rotational speed and torque, the gearbox helps maintain efficient operation, preventing losses and ensuring that the potatoes are harvested with minimal damage.

4. Cost-Effective Maintenance

- Potato harvester gearboxes are designed for easy maintenance, which helps reduce overall operational costs. With proper care and servicing, these gearboxes can last longer, thus lowering the need for frequent replacements. Their modular design also allows for easier repairs, which minimizes downtime during the harvesting season.

5. Versatility and Adaptability

- Many potato harvester gearboxes are designed to be versatile, capable of adapting to various models of harvesters and different field conditions. This flexibility ensures that they can be used across multiple operations, providing value for farmers with varying needs.

By choosing high-quality gearboxes for potato harvesters, farmers can maximize productivity, reduce operational costs, and ensure the longevity of their equipment. The gearbox is an essential part of ensuring smooth and efficient operations throughout the harvesting season.

|

|

Working Principle of Tractor PTO Driven Potato Harvester Gearbox

A PTO-driven potato harvester gearbox plays a crucial role in efficiently transferring power from the tractor’s Power Take-Off (PTO) system to the various mechanisms involved in potato harvesting. The gearbox ensures the optimal performance of the harvester by regulating and distributing power to different parts of the machine, allowing for smooth, efficient, and reliable operation. Below is an overview of how the working principle of the PTO-driven potato harvester gearbox works:

1. Power Transfer from the Tractor to the Gearbox

- PTO Shaft Engagement: The process begins with the tractor’s engine power being transmitted through the PTO shaft. The PTO system of the tractor generates mechanical power (rotational torque) and transfers it through the PTO shaft connected to the harvester’s gearbox.

- Rotation Input: As the tractor’s engine operates, the PTO shaft rotates at a set speed (typically around 540 or 1000 RPM, depending on the tractor). This rotational power is then fed into the gearbox, where it is processed and redistributed to the various components of the potato harvester.

2. Gearbox Power Distribution

- Reduction and Speed Control: The primary function of the gearbox is to reduce the rotational speed of the PTO input to a level suitable for the harvester’s working mechanisms. The tractor’s PTO generally operates at higher speeds (e.g., 540 RPM), but various harvester functions like the digging, cleaning, and conveyor systems require lower speeds. The gearbox uses a combination of gears (such as planetary, bevel, or helical gears) to reduce the input speed and ensure that each part operates at the correct speed.

- Torque Multiplication: In addition to speed reduction, the gearbox often multiplies torque to provide the necessary power for digging, lifting, and separating potatoes from the soil. The increased torque is essential to power the mechanical systems of the harvester, especially when working in tough soil conditions.

3. Power Transmission to Various Components

- Digging Mechanism: The gearbox transmits power to the digging components, which consist of a set of rotating blades or share points that loosen the soil and dig up the potatoes. The rotational motion is typically transferred through a chain, belt, or shaft system.

- Conveyor System: The power from the gearbox also drives the conveyor belt or elevator, which carries the harvested potatoes from the soil to the cleaning and separation systems. The conveyor system requires steady and efficient power transmission to move the potatoes without damaging them.

- Separation and Cleaning Mechanism: The gearbox powers the cleaning system, which often includes vibrating sieves or rotating drums that separate the soil, stones, and debris from the potatoes. This ensures that only clean potatoes are collected for storage or transport.

- Additional Systems: Depending on the model of the harvester, the gearbox may also drive other systems such as lifting mechanisms, soil sifting equipment, or auxiliary tools designed to improve the overall harvesting efficiency.

4. Variable Speed Control (if applicable)

- Some advanced potato harvester gearboxes include the feature of variable speed control, which allows operators to adjust the speed of specific components (e.g., conveyor belts or digging mechanisms) to suit different field conditions. This feature optimizes the harvester’s operation by providing more control over the performance, ensuring maximum efficiency in varying soil types and field conditions.

5. Efficiency and Synchronization

- The gearbox ensures that all components of the potato harvester operate in perfect synchronization, allowing the machine to work at its maximum efficiency. By adjusting the torque and rotational speed for different components, the gearbox ensures that the digging, conveying, and cleaning processes are balanced and efficient, minimizing energy loss and optimizing fuel consumption.

In essence, the working principle of the PTO-driven potato harvester gearbox is based on efficiently converting the tractor’s high-speed PTO output into the controlled, reliable power required for the diverse harvesting functions, thereby optimizing the machine’s overall performance.

About FMP

Based in Italy, FMP is a leading manufacturer specializing in the design, development, and production of high-performance gearboxes, with a core focus on the agricultural machinery sector. Renowned for its precision engineering, innovative solutions, and unwavering reliability, FMP has built a strong reputation as a trusted partner in both agricultural and industrial markets. Our expansive product portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a variety of essential components, each meticulously crafted to meet the unique requirements of different applications.

At FMP, we recognize that every client faces distinct challenges. This insight drives our commitment to delivering tailored solutions, whether for individual components or fully integrated systems. Through close collaboration with our clients, we ensure that each solution not only fulfills their specific needs but also enhances performance and maximizes value. Our focus on prompt, professional responses and expert guidance ensures that every inquiry is addressed with precision, guaranteeing the best outcomes, every time.

We emphasize continuous and transparent communication throughout the entire product development process. Our dedicated team works closely with clients to thoroughly understand their requirements and provide valuable insights and recommendations to achieve optimal results. Whether developing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time and without compromise. Our mission is to consistently exceed client expectations, delivering outstanding service and exceptional results with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards and enforce rigorous quality control measures to ensure that every product not only meets but exceeds industry benchmarks. This unwavering commitment to excellence, combined with our core values of integrity, teamwork, and perseverance, has allowed us to establish long-term, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always eager to foster global partnerships, providing expert advice and customized solutions that address the evolving needs of our clients. We are dedicated to building long-term, mutually beneficial relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is ready to help you overcome technical challenges and ensure your continued success.

Author: CX