Product Specifications:

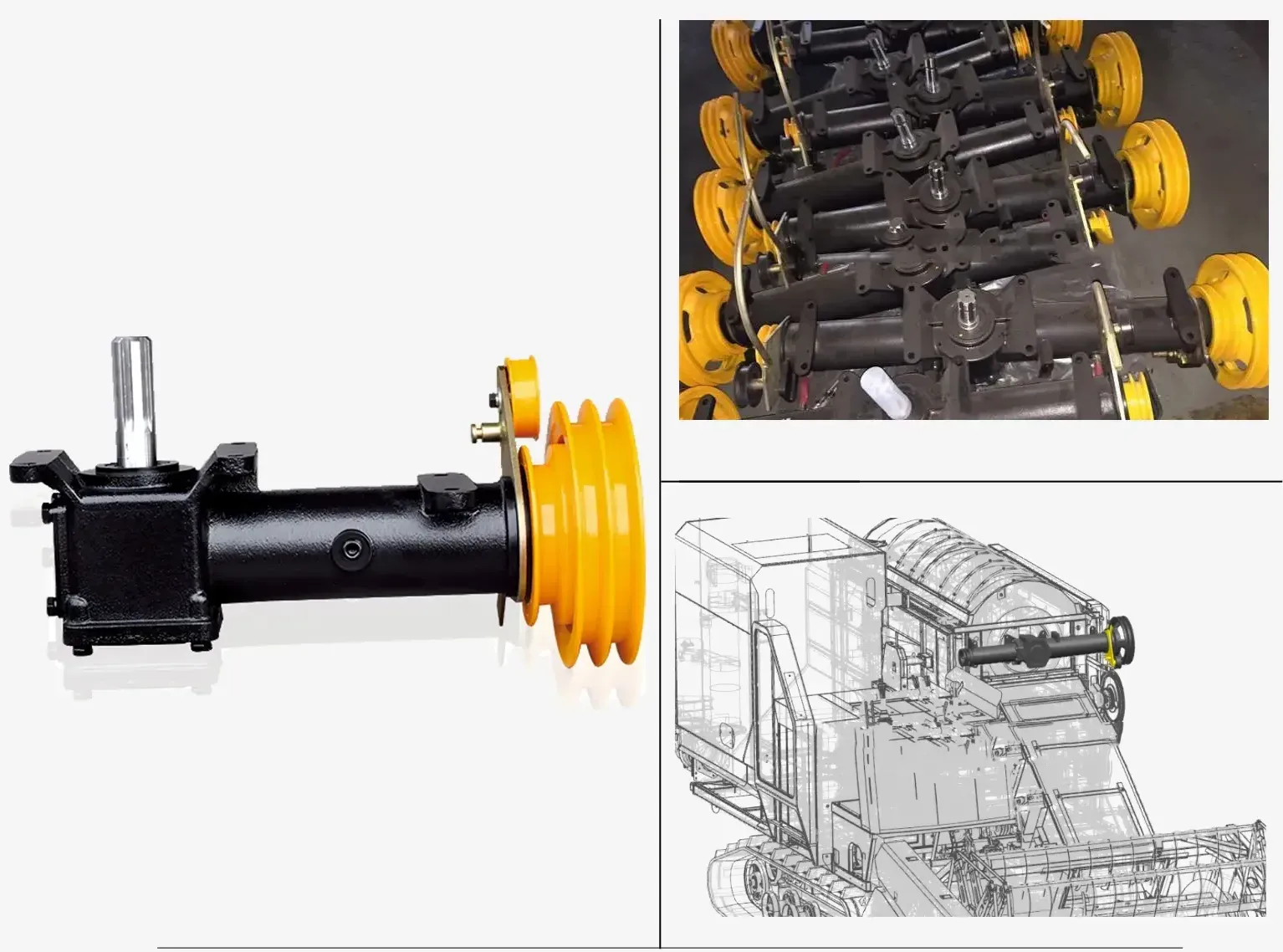

| Product Name | Short harvester reversing for rice harvester |

| Material | QT450 for housing, 20CrMnTi for gear shaft. |

| Color | Customization |

| Model | FMP-1.6Z.03-05 |

| Used | Rice harvester |

Advantages of Using the Combine Harvester Reversing Gearbox

The Combine Harvester Reversing Gearbox offers several significant advantages that enhance the efficiency and functionality of the harvester. Here are some key benefits of using this specialized gearbox:

1. Improved Maneuverability

- The reversing gearbox allows the combine harvester to reverse easily without the need for complex maneuvers or stopping and turning around. This is particularly useful in tight spaces or when adjusting positioning in the field, improving overall operational efficiency.

2. Increased Operational Efficiency

- With a reversing gearbox, the combine harvester can change direction quickly without having to disengage or shift between gears. This allows for smoother and faster transitions when moving in and out of areas with dense crops, reducing downtime and improving harvesting efficiency.

3. Enhanced Productivity

- By enabling quick reversal without stopping, operators can avoid delays and reduce the time spent repositioning the machine. This leads to higher overall throughput during the harvesting process, especially in fields that require frequent direction changes due to obstacles, turns, or uneven terrain.

4. Greater Versatility

- The reversing gearbox provides greater flexibility in working conditions. It helps the harvester adapt to a variety of tasks, such as clearing crop residue, reversing to adjust header positions, or navigating around obstacles, all without the need to shift to a different gear or stop working.

5. Reduced Wear and Tear

- The gearbox allows for smoother operation when reversing, reducing the wear on other critical components like the clutch and transmission. It also minimizes the need for manual intervention, extending the lifespan of the vehicle’s drivetrain and reducing the risk of mechanical failures.

In summary, the Combine Harvester Reversing Gearbox offers benefits such as increased maneuverability, operational efficiency, and productivity, while also improving safety, reducing wear and tear, and enhancing fuel efficiency. These advantages make it an indispensable component in modern combine harvester operations, ensuring both time and cost savings for farmers.

Key Components of Combine Harvester Reversing Gearbox

The Combine Harvester Reversing Gearbox is a critical component in modern combine harvesters, enabling the machine to reverse efficiently and smoothly without manual shifting. It integrates various mechanical components that work together to provide reliable power transmission and control. Here are the key components of a combine harvester reversing gearbox: