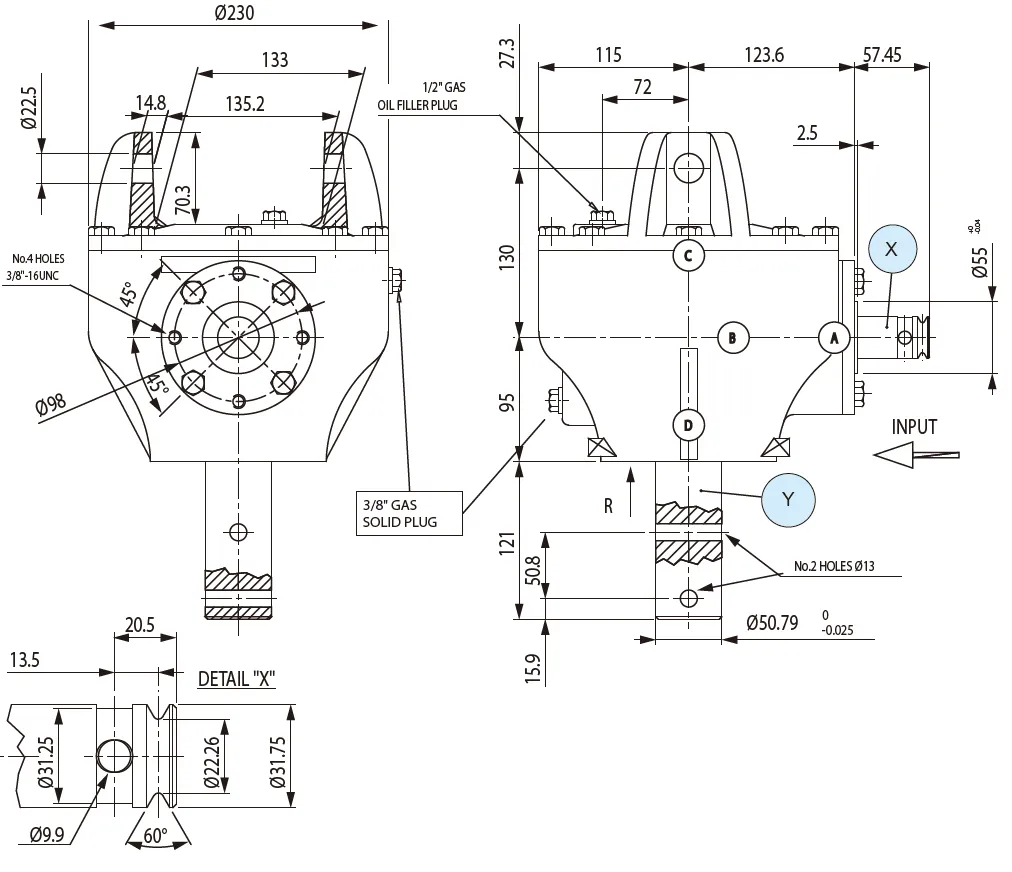

75 HP Heavy Duty Post Hole Digger Gearbox Dimensions

Product Specifications:

– 75 HP Rating

– Includes Guards

– 3:1 Ratio

– 1-1/4″ Round Input Shaft w/ 3/8″ mounting hole

– 2″ Round Output Shaft with dual 1/2″ holes for mounting augers

– 7/8″ Mounting Pin, 7-1/2″ Long

– Mounting ears 5-3/8″ inside & 6-5/8″ outside to outside.

– Durable black paint

– 75 lbs

– Shipped Without Oil ( 80W-90 Gear Oil)

75 HP Heavy Duty Post Hole Digger Gearbox Parts

The 75 HP Heavy Duty Post Hole Digger Gearbox is a sturdy component engineered to meet the high torque requirements for drilling in tough soil conditions. Below are the main parts of this gearbox:

Gearbox Housing: The gearbox housing provides protection and structural support for the internal components. Typically crafted from durable materials like cast iron or steel, it is designed to endure the rigors of heavy-duty drilling operations.

Input Shaft: Connecting to the tractor’s PTO (Power Take-Off) shaft, the input shaft transfers rotational power from the tractor’s engine to the gearbox. It serves as the primary driver for the gearbox, initiating the drilling process.

Gears: Inside the gearbox, a series of gears transmit power from the input shaft to the output shaft while adjusting torque and speed. These gears are meticulously engineered to deliver the necessary torque amplification for effective drilling in various soil types.

Output Shaft: The output shaft receives power from the gears and transmits it to the drilling auger. By rotating the auger, this shaft facilitates the creation of planting holes at the required depth and diameter.

Bearings: Bearings support the shafts and gears within the gearbox, ensuring smooth rotation with minimal friction. High-quality bearings are crucial for maintaining both the efficiency and longevity of the gearbox, especially under heavy loads during continuous operation.

Seals: Seals are essential for preventing dirt, moisture, and other contaminants from entering the gearbox housing and lubrication system. By maintaining the integrity of the gearbox, these seals help to avert premature wear or damage to the internal components.

Features of the 75 HP Heavy Duty Post Hole Digger Gearbox

The 75 HP Heavy Duty Post Hole Digger Gearbox is designed for optimal performance and durability in demanding drilling applications. Here are its key features:

1. High Torque Capacity

Engineered to handle high torque demands, this gearbox efficiently transfers power for drilling in tough soil conditions, ensuring effective operation.

2. Robust Construction

Constructed from durable materials such as cast iron or steel, the gearbox housing provides excellent structural integrity and resistance to wear and tear.

3. Precision Gears

The gearbox features precisely engineered gears that optimize torque and speed, allowing for efficient drilling while adapting to varying soil types.

4. Efficient Power Transfer

With a reliable input shaft connecting to the tractor’s PTO, the gearbox facilitates smooth power transfer from the tractor engine, enhancing overall performance.

5. Enhanced Longevity

High-quality bearings minimize friction and wear, contributing to the longevity of the gearbox, even under continuous heavy loads.

6. Effective Sealing System

Seals are integrated to protect the internal components from dirt and moisture, helping to maintain lubrication and prevent premature damage.

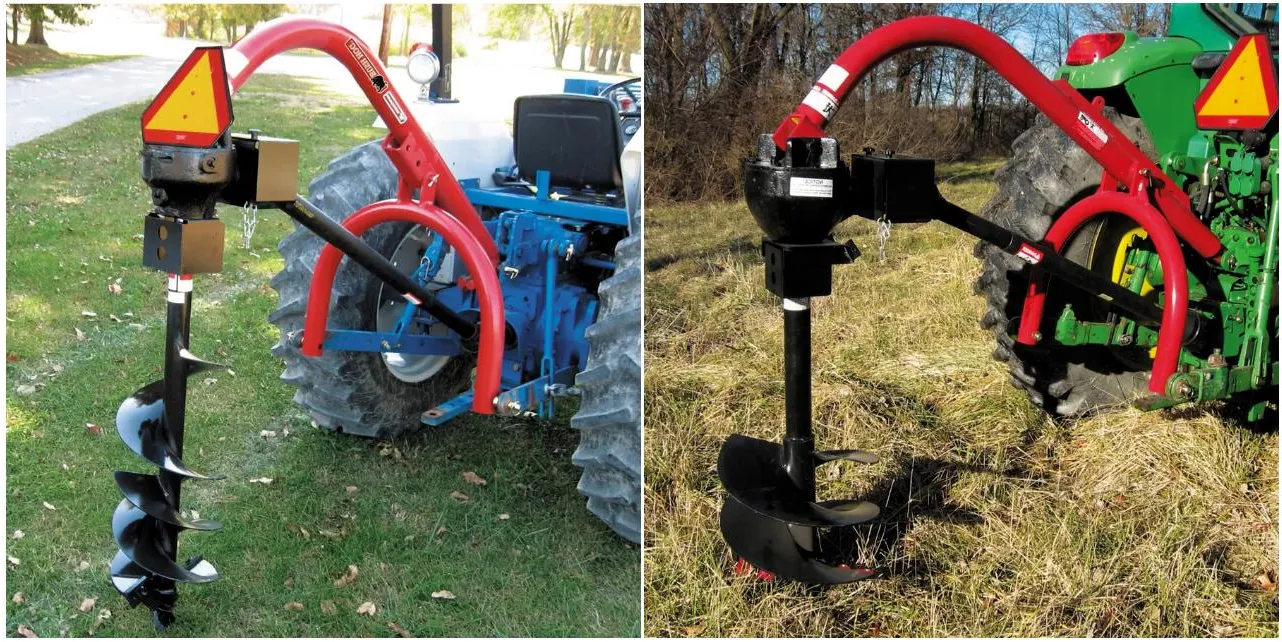

7. Versatile Application

Suitable for various soil conditions, this gearbox is ideal for agricultural, landscaping, and construction applications, making it a versatile choice for post hole digging.

8. Easy Maintenance

The design allows for straightforward maintenance, ensuring that users can easily access components for inspections and servicing.

These features make the 75 HP Heavy Duty Post Hole Digger Gearbox a reliable choice for professionals requiring efficient and durable drilling solutions.

About FMP

FMP, based in Italy, is dedicated to the research, development, and manufacturing of a wide range of gearboxes, reducers, and engineering machinery. Our product portfolio includes:

- Spiral Bevel Gearboxes

- Straight Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

These products cater to various applications, including agricultural mowers, snow plows, fertilizer spreaders, grain conveyors, industrial equipment, oil extraction machinery, marine industry equipment, and hydraulic components for engineering.

At FMP, we pride ourselves on our robust technical and research capabilities. Our commitment to producing reliable and high-quality products has earned us a stellar reputation in the manufacturing sector. We embrace a unique business philosophy that emphasizes innovation, quality, and customer satisfaction, ensuring that we meet the evolving needs of our clients.

Manufacturing Process for Agricultural Gearboxes

The production process for agricultural gearboxes is intricate and involves several key steps:

- Product Design: This initial phase includes selecting specifications, materials, and dimensions for the gearbox to meet specific application requirements.

- Raw Material Preparation: We prepare essential materials, predominantly cast iron or aluminum alloy, ensuring that they meet our stringent quality standards.

- Precision Machining: The raw materials undergo precision machining, which includes turning, milling, and other operations, to fabricate gears, shafts, and housings with high accuracy.

- Assembly: Components such as gears, bearings, and shafts are meticulously assembled within the housing. During this stage, we check and calibrate for precision and apply appropriate lubricants to ensure smooth operation.

- Process Treatment: Gearboxes are subjected to heat treatment, enhancing their strength and wear resistance for long-lasting performance.

- Surface Treatment: We implement surface treatments such as polishing and powder coating to improve both the aesthetic appeal and corrosion resistance of the gearboxes.

- Quality Control: Rigorous quality inspections are conducted, measuring dimensions, precision, noise, and vibration to ensure that our gearboxes meet safety and performance standards.

Overall, the production of agricultural gearboxes is a complex process that requires skilled craftsmen, advanced manufacturing equipment, and a comprehensive quality control system. This meticulous approach ensures that our gearboxes deliver exceptional performance and reliability.

Author: CX