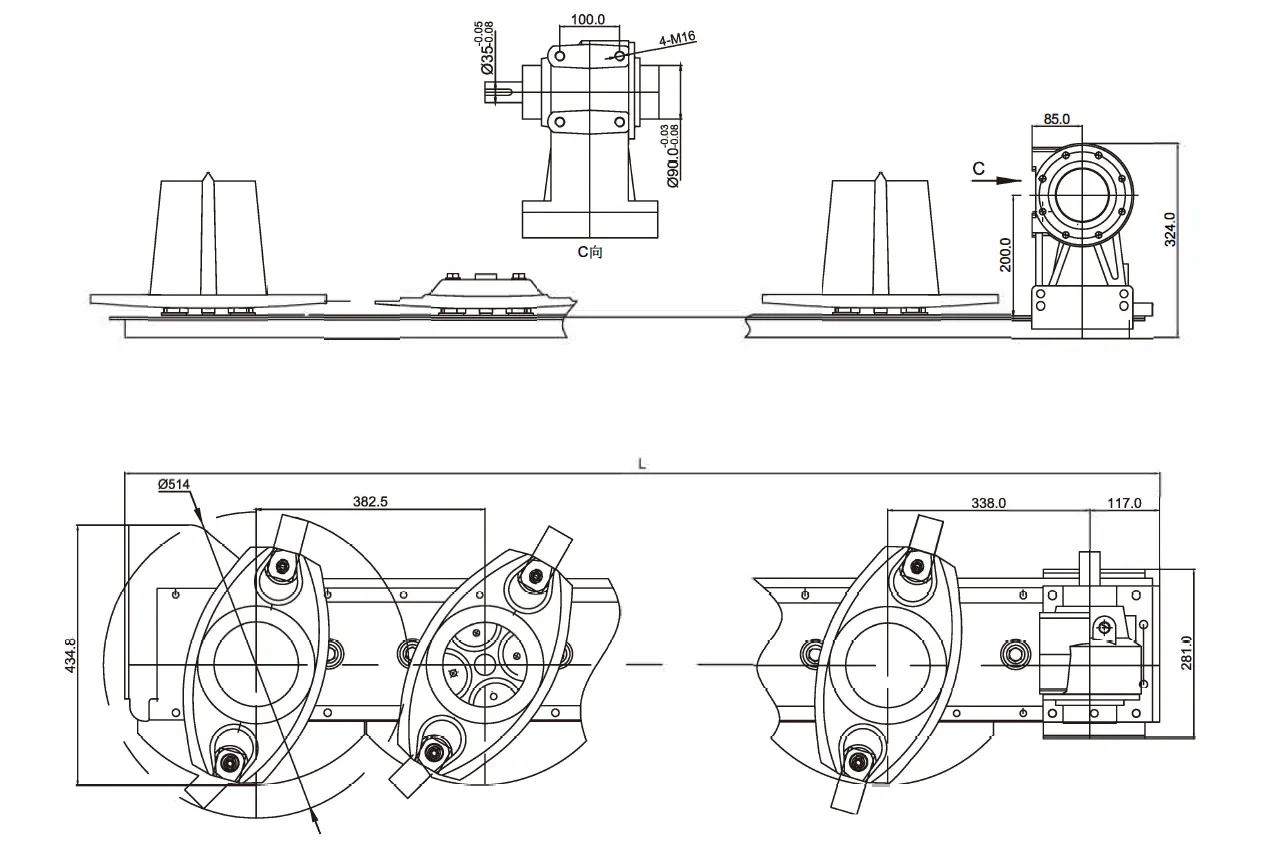

3-Point Hitch Mower Cutter Bar FMP-GC Dimensions

3-Point Hitch Mower Cutter Bar FMP-GC Technical Data

3-Point Hitch Mower Cutter Bar FMP-GC Technical Data

| Model number | FMP-GC04 | FMP-GC05 | FMP-GC06 | FMP-GC07 |

| Weight(kg) | 148 | 168 | 197 | 226 |

| MOP (kw/hp) | 21/28 | 26/35 | 31/42 | 37/50 |

| Overall length (mm) | 1821.8 | 2221.4 | 2586.3 | 2981.4 |

| Work breadth (m) | 1.65 | 2.1 | 2.4 | 2.8 |

| cutter number (n) | 4 | 5 | 6 | 7 |

| Number of blades (n) | 8 | 10 | 12 | 14 |

| Rpm input (r/min) | 1000 | |||

| Rpm output (r/min) | 2667 | |||

| Remark: If you have any special require feel free let me know, we also accept custom. | ||||

Tractor-mounted Mower Cutter Bar FMP-GC for Disc Mowers

| Disc mowers | Knife beam Type | Cutting width | Number of discs | Number of blades | Disc speed | Disc Dia. | travel speed | Matched power | PTO | weights | note |

| YS1650 | KLF-GC04 | 1.65m | 4 | 2 blades/3 blades | 2900 | 19.7in.(500mm) | 4-12 km/h | 40hp-210hp | Cat2 | 500kg | normal type |

| YS2100 | KLF-GC05 | 2.1m | 5 | 2 blades

|

2900 | 19.7in.(500mm) | 4-12km/h | 50hp-210hp | Cat2 | 550kg | normal type |

| YS2450 | KLF-GC06 | 2.45m | 6 | 2 blades/3 blades | 2900 | 19.7in.(500mm) | 4-12km/h | 70hp-210hp | Cat2 | 590kg | Normal/Enhanced |

| YS2860 | KLF-GC07 | 2.86m | 7 | 2 blades | 2900 | 19.7in.(500mm) | 4-12km/h | 90hp-210hp | Cat2 | 629kg | Normal/Enhanced |

| YS3200 | KLF-GC08 | 3.20m | 8 | 2 blades/3 blades | 2900 | 19.7in.(500mm) | 4-12km/h | 100hp-210hp | Cat2 | 707kg | Enhanced Type |

3-Point Hitch Rotary Disc Mower Agricultural Applications

The 3-Point Hitch Rotary Disc Mower is a versatile and efficient piece of equipment widely used in agricultural operations for mowing, haymaking, and land management. Designed for attachment to a tractor’s 3-point hitch system, this mower provides reliable, high-performance cutting of grass, hay, and other vegetation in various agricultural settings. Below are some of the key agricultural applications for the 3-Point Hitch Rotary Disc Mower:

Pasture Mowing

- The rotary disc mower is commonly used for mowing large areas of pasture. Whether it’s for livestock grazing or hay production, this mower provides fast and efficient cutting of pasture grasses. Its precision cutting mechanism ensures a clean and uniform cut, which is essential for maintaining healthy pasture conditions.

Hay Cutting

- The 3-point hitch rotary disc mower is a critical tool in hay production. It is used to cut grass or legumes (like alfalfa) at the right stage of growth to produce high-quality hay. The mower’s design allows for clean cuts without causing excessive damage to the crop, which is crucial for preserving the quality of the hay when it is dried and baled.

Land Clearing

- This mower is ideal for clearing unwanted vegetation and brush from agricultural land. It can handle dense grass, weeds, and light brush, making it effective for reclaiming land for farming or creating clear areas for new crops. Its ability to cut through thick vegetation helps prepare land for planting and improves the accessibility of otherwise difficult-to-manage fields.

Roadside and Ditch Maintenance

- Municipalities and agricultural operations use the rotary disc mower for roadside mowing and ditch maintenance. It is perfect for cutting grass and vegetation along roadsides, highways, and drainage ditches. This application is essential for maintaining clear visibility, safety, and preventing overgrowth that could obstruct water flow in drainage systems.

Field and Crop Maintenance

- The rotary disc mower is also employed in routine field maintenance to manage weeds, overgrowth, and excess crop residue. It is particularly effective in clearing weeds or cutting excess growth between crop rows, ensuring that crops have the space and nutrients they need to grow.

The 3-Point Hitch Rotary Disc Mower is an indispensable tool in various agricultural applications. Whether it’s for pasture management, hay production, land clearing, or field maintenance, this mower provides efficient, high-quality performance. Its versatility in handling different types of vegetation and its ability to work in diverse agricultural environments make it a reliable choice for farmers and land managers.

Advantages of the 3-Point Hitch Mower Cutter Bar (Tractor-Mounted Mower Cutter Bar) FMP-GC

The 3-Point Hitch Mower Cutter Bar (also known as the Tractor-mounted Mower Cutter Bar) FMP-GC offers numerous benefits for agricultural and landscaping applications. Designed for efficiency and durability, this mower cutter bar is engineered to meet the demanding requirements of professional lawn care, pasture mowing, and field maintenance. Below are the key advantages of the FMP-GC Tractor-mounted Mower Cutter Bar:

- Efficient Cutting Performance:

- The FMP-GC mower cutter bar is designed for optimal cutting efficiency. It enables consistent and precise cutting, ensuring uniform results across large fields, pastures, or roadside areas. The cutter bar allows for smooth operation and high-performance cutting, even in dense vegetation or overgrown areas.

- Improved Maneuverability:

- Mounted on a 3-point hitch, the FMP-GC mower cutter bar offers excellent maneuverability, making it easy to handle and navigate around obstacles, narrow spaces, or complex terrain. This flexibility helps users achieve cleaner cuts with minimal effort, improving overall operational efficiency.

- Durability and Long-Lasting Performance:

- Constructed from high-quality materials, the FMP-GC mower cutter bar is built to withstand the rigors of heavy-duty use. Whether it’s cutting tough grass or clearing brush, the sturdy design ensures long-term reliability and durability, reducing the need for frequent repairs or replacements.

- Versatility and Adaptability:

- The FMP-GC cutter bar is compatible with a variety of cutting attachments, making it suitable for different agricultural and landscaping needs. It can be easily adapted to different types of mowers, such as rotary cutters or flail mowers, offering versatility for a wide range of applications including field maintenance, pasture mowing, and land clearing.

The 3-Point Hitch Mower Cutter Bar FMP-GC is a durable, efficient, and versatile solution for professional mowing and field maintenance. Whether used for pasture mowing, land clearing, or roadside maintenance, it offers improved maneuverability, long-lasting performance, and reduced operational costs, making it a top choice for agricultural and landscaping professionals.

Precautions for Using the 3-Point Hitch Rotary Disc Mower

Precautions for Using the 3-Point Hitch Rotary Disc Mower

The 3-Point Hitch Rotary Disc Mower is a powerful and efficient tool used in various agricultural applications. However, to ensure safe and optimal performance, operators must follow certain precautions. Below are the key precautions for using the 3-point hitch rotary disc mower:

Proper Installation and Attachment

- Ensure Secure Attachment: Always check that the mower is securely attached to the tractor’s 3-point hitch before operation. Loose or improperly connected equipment can result in instability or detachment during use, leading to potential accidents or damage.

- Correct Alignment: Make sure the mower is properly aligned with the tractor’s PTO (Power Take-Off) shaft to ensure proper power transfer and avoid undue stress on the machine and tractor.

Check for Tractor Compatibility

- Match Tractor Power to Mower Requirements: Ensure that the tractor’s horsepower and PTO speed match the specifications of the rotary disc mower. Using a tractor that is too small or not powerful enough can strain the equipment, leading to inefficiency or potential damage.

Pre-Operation Inspection

- Inspect Components: Before each use, inspect the mower’s blades, PTO shaft, and all moving parts for wear and damage. Replace any worn or damaged components immediately to prevent accidents and maintain performance.

- Check for Loose Bolts or Fasteners: Tighten any loose bolts or fasteners to prevent parts from becoming dislodged during operation, which could cause damage or pose safety risks.

Safety Precautions

- Disconnect PTO Before Maintenance: Always disconnect the tractor’s PTO and turn off the engine before performing any maintenance, adjustments, or repairs on the mower.

- Wear Safety Gear: Always wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and sturdy footwear, while operating or maintaining the mower.

- Keep Clear of Blades: Never approach the mower’s cutting area when it is in motion. Keep a safe distance from the blades and other moving parts to avoid injury.

Adjust Mower Height and Cutting Settings

- Adjust Cutting Height: Set the mower to the correct cutting height according to the type of vegetation and the desired cut. Operating the mower at the wrong height can result in uneven cutting or unnecessary stress on the mower.

- Check Blade Position: Ensure that the blades are positioned correctly to achieve an even cut, and that they are sharp and free from debris.

Monitor Tractor Speed and PTO RPM

- Avoid Over-speeding: Operate the tractor at the recommended speed for optimal performance. Over-speeding the tractor or PTO shaft can cause excessive wear on the mower and reduce its lifespan.

- Maintain Proper PTO RPM: Ensure that the PTO operates at the recommended RPM. Running the PTO at incorrect speeds can result in inefficient power transfer, excessive wear on the mower, and potential damage to the machine.

Observe Terrain Conditions

- Avoid Rocks and Debris: Before operating the mower, clear the area of rocks, large sticks, and other debris that could damage the blades or cause the mower to malfunction.

- Work on Level Ground: Operate the mower on relatively flat, level terrain to avoid tipping or imbalances that could damage the mower or tractor.

- Be Cautious of Slopes: When working on slopes or uneven terrain, reduce speed and ensure the tractor’s stability. A sudden shift in weight can cause the tractor to tip or cause damage to the mower.

Regular Maintenance and Lubrication

- Lubricate Moving Parts: Regularly lubricate all moving parts of the mower to ensure smooth operation and reduce wear and tear. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants to use.

- Check Oil Levels: Ensure that all gearboxes and hydraulic components are filled with the correct type and amount of oil. Low oil levels can lead to overheating and mechanical failure.

- Clean After Use: After each use, clean the mower to remove grass, debris, and soil buildup that can clog the mower and reduce efficiency. A clean mower performs better and lasts longer.

Avoid Excessive Overloading

- Monitor Load on Mower: Avoid overloading the mower by attempting to cut excessively tall or dense vegetation that the mower is not designed to handle. Excessive strain on the mower can lead to damage or overheating of components.

- Cut in Stages: For particularly dense or tall vegetation, consider cutting in stages or reducing the cutting height to prevent overloading the mower.

Storage and Transportation

- Store Properly: After use, store the rotary disc mower in a dry, clean, and secure location to prevent rusting and damage. Ensure that the mower is not exposed to harsh weather conditions.

- Transport Safely: When transporting the mower, ensure it is properly secured to avoid shifting during movement. Use appropriate safety flags or lights when transporting on public roads to alert other drivers.

Stay Within Operator Capacity

- Limit Operating Time: While the 3-point hitch rotary disc mower is designed for heavy-duty use, it’s important to avoid continuous operation for extended periods without breaks. Allow the mower and tractor to cool down periodically to prevent overheating and ensure optimal performance.

By following these precautions, operators can ensure safe, efficient, and long-lasting performance from their 3-Point Hitch Rotary Disc Mower. Proper care, regular maintenance, and safe operational practices help maximize the mower’s effectiveness while reducing the risk of accidents and premature wear.

|

|

|

|

Author: CX