Plastic Gear Rack

If the product you need is not listed, go ahead and get a free quote!

Types of Plastic Gear Rack

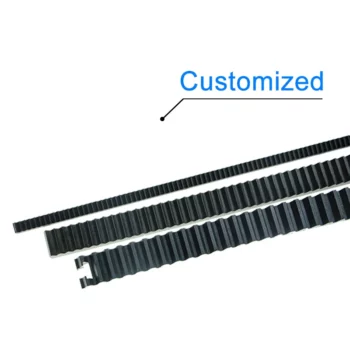

Nylon CNC Plastic Gear Rack Wear Resistant Rack Pinion

Good Tensile Strength Nylon Plastics Rack for Sliding Gate

Factory Plastic Rack Gear Customized Nylon Gear Rack

Injection Rack Pinion Gear Plastic Gear Rack

Plastic Manufacturers Injection Molding Corrosion Resistant Mc Nylon Industrial Conveyor Rack Gear

Injection Molding Manufacturers Wear-resistant Corrosion Resistant Mc Nylon Pa66 Plastic Gear Rack

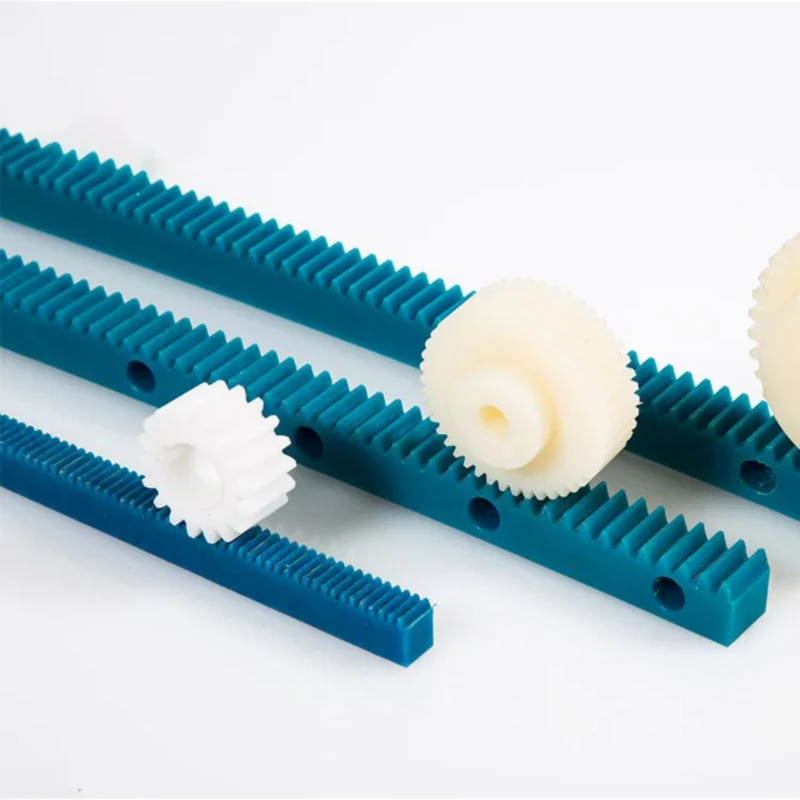

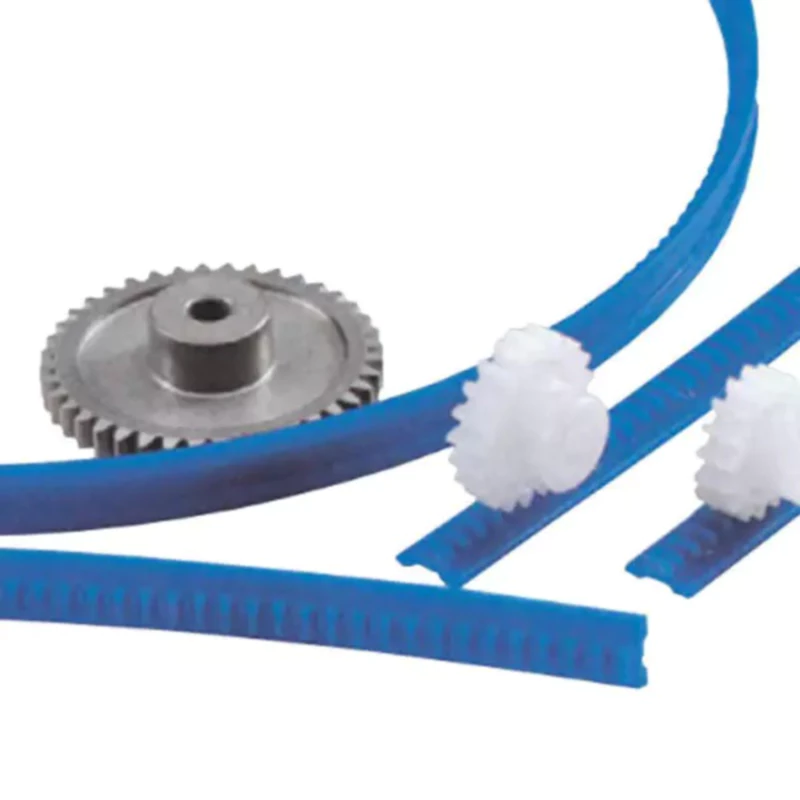

Flexible Gear Rack and Pinion High Precision Polyamide Nylon PA66 Plastic Gear Rack

Durable Cnc Precision Machining Parts Custom Nylon Pa6 Plastic Rack Gear

Self-lubrication Flexible Mc Nylon Gears Rack Plastic Nylon66 Gear Rack

CNC nylon rack plastic MC901 gear rack for sliding gate

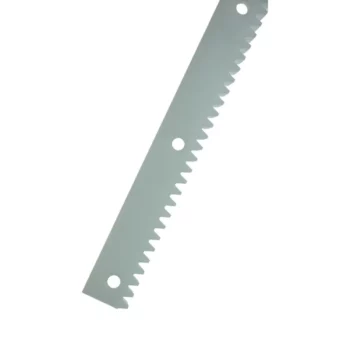

high impact resistance cnc rack and pinion flexible mc nylon rack gear

plastic gear rack pinion good Anti-Corrosion Resistance EPA Gear Rack

plastic gear rack and pinion nylon gear rack for sliding gate

High Precision Nylon Plastic Gear Racks Pinion

Engineering Plastic Injection Nylon Plastic Gear Rack Low Noise Plastic Rack

Customized machining plastic or stainless steel straight pinion plastic gear racks

Plastic Gear Rack: Precision and Performance for Italian Industries

Plastic racks are key components in machinery, automation systems and steering mechanisms that convert rotary motion into precise linear motion. Unlike traditional metal racks, plastic racks made from high-performance materials such as nylon and polyoxymethylene (POM) offer unique advantages, including corrosion resistance, low noise and self-lubricating properties, making them an ideal choice for a wide range of industries in Italy.

Why Choose Plastic Gear Racks?

Plastic gear racks, particularly those with a 20° pressure angle, are the industry standard due to their thicker, stronger teeth compared to 14½° alternatives. Manufactured from materials like food-grade nylon and white POM, they excel in environments requiring hygiene, such as food-processing plants or scientific applications. Key benefits include:

- Durability and Wear Resistance: Nylon and acetal gear racks resist wear, dirt, and dust, ensuring long-lasting performance.

- No Lubrication Required: Self-lubricating properties make them suitable for challenging environments, such as CNC machines or rail systems.

- Quiet Operation: Plastic gear racks run quieter than metal, perfect for noise-sensitive applications.

- Corrosion and Chemical Resistance: Ideal for industries where metal components may degrade.

Plastic gear racks deliver precision and reliability for applications like automation systems and elevators.

Applications of Plastic Gear Racks

Plastic gear racks are versatile, supporting a range of industries across Italy:

- CNC Machines: In Milan’s industrial zones, gear racks ensure precise motion control.

- Food Processing: Bologna’s food sector benefits from food-grade POM gear racks that meet strict hygiene standards.

- Automation Systems: From Venice to Florence, gear racks drive robotics and conveyor systems.

- Steering Mechanisms: Used in vehicles and machinery across Italy, ensuring smooth operation.

Their lightweight design and high load capacity make them a top choice for engineers seeking efficiency and performance.

Technical Specifications of Module 1 Plastic Gear Rack

Our Module 1 plastic gear rack, made from white POM, is a prime example of quality engineering. Key specifications include:

- Dimensions: 15mm (b) x 15mm (H) x 14mm (h), with a nominal length of 250mm.

- Module: 1, adhering to DIN 867/DIN 3972 standards.

- Pressure Angle: 20°, ensuring compatibility with standard spur gears.

- Weight: Only 75 grams, ideal for lightweight assemblies.

- Material: Food-grade POM, suitable for abrasive and scientific applications.

This gear rack pairs seamlessly with matching spur gears, enabling smooth linear motion in applications from robotics in Bologna to rail systems in Venice.

About FMP: Your Trusted Partner for Plastic Gear Racks

At FMP, we specialize in manufacturing a wide range of plastic gear racks, including nylon and acetal (POM) products, designed to meet the needs of industries across Italy. Based on the expertise of the Plastic Machining Company, we produce OEM and metal-replacement gear racks that match industry standards while offering superior wear resistance and quiet operation. Our product line includes the full Poly-Hi Solidur range, ensuring versatility for applications in Milan, Venice, Florence, Bologna, and beyond.

We understand that your project may require unique specifications. That’s why we offer custom plastic gear racks tailored to your exact needs. If you don’t find the model you’re looking for in our product list, don’t worry—it may not yet be uploaded. Simply email us with your requirements, and our engineers will respond within 24 hours with a solution. Contact FMP today to elevate your machinery with precision-engineered plastic gear racks, proudly serving Italy’s innovative industries.