The Wt-3000Psi Welded Tee Hydraulic Cylinder by Direct Supply is a premier product from FMP, a renowned manufacturer established in 2006. Known for its commitment to quality and innovation, FMP has designed this hydraulic cylinder specifically for high-pressure applications, ensuring it meets the rigorous demands of various industrial tasks. With a focus on durability and efficiency, the Wt-3000Psi model stands out as a reliable choice for professionals seeking powerful hydraulic solutions.

Key Features and Advantages

- High Capacity:

The Wt-3000Psi hydraulic cylinder is engineered to withstand pressures of up to 3000 PSI, making it ideal for heavy-duty applications. This high capacity allows it to handle substantial loads and perform effectively in challenging environments, such as construction sites, manufacturing facilities, and agricultural operations. - Durability:

Featuring a welded tee design, this hydraulic cylinder is built to last. The robust construction minimizes the risk of leaks and structural failures, ensuring long-lasting performance even under extreme operating conditions. This durability translates into reduced maintenance costs and downtime, making it a cost-effective investment for businesses. - Efficiency:

Designed for smooth operation, the Wt-3000Psi hydraulic cylinder delivers excellent performance while optimizing energy usage. Its efficient design minimizes hydraulic fluid consumption, contributing to lower operational costs and a reduced environmental footprint. This efficiency is crucial in maximizing productivity in various applications.

Technical Specifications

The technical specifications of the Wt-3000Psi Welded Tee Hydraulic Cylinder include its dimensions, weight, connection types, and other essential parameters that define its performance and compatibility with hydraulic systems. Understanding these specifications is vital for ensuring proper integration into existing machinery and achieving optimal results.

| Specification | Description |

|---|---|

| Maximum Pressure | 3000 PSI |

| Stroke Length | Customizable |

| Material | High-strength steel |

| Connection Type | Flanged or threaded |

| Weight | Varies by size |

Hydraulic Systems and Working Principle

Hydraulic Systems and Working Principle

The hydraulic cylinder operates on the fundamental principle of converting hydraulic energy into mechanical energy. This process begins with the movement of hydraulic fluid, which is pumped into the cylinder. As the fluid enters, it exerts pressure on the piston inside the cylinder.

This pressure-driven movement of the piston generates linear force, which is then utilized to perform various tasks, such as lifting, pushing, or pulling heavy loads. The ability to control the speed and direction of the piston allows for precise operations in a wide range of applications.

The Wt-3000Psi Welded Tee Hydraulic Cylinder by Direct Supply is a powerful and dependable component designed for high-pressure environments. Its unique features and efficient operation make it an essential tool for industries that require robust hydraulic solutions, ensuring safety, reliability, and enhanced productivity.

Product History and Maintenance

The history of the Wt-3000Psi Welded Tee Hydraulic Cylinder is a testament to FMP’s commitment to quality and innovation. Regular maintenance ensures longevity and efficient functioning of the hydraulic cylinder.

Advantages of Welded Tee Type Cylinder

-

- Increased Strength: Welded tee type cylinders are known for their high strength, making them suitable for applications requiring heavy lifting. The welding process used during the fabrication of these cylinders ensures that the cylinder is free from weak points and can withstand high pressure and stress.

When pressure is exerted on the cylinder, it distributes evenly across the entire surface, making it resistant to deformation. This feature ensures that the cylinder can maintain its shape and structural integrity even under extreme conditions.

-

- Leakage Prevention: Welded tee type cylinders are designed to prevent leakage. The welding process used during the fabrication process ensures that the cylinder is completely sealed and free from any possible leakages. This feature makes them suitable for use in applications where leakage could cause severe damage or injury.

The welded joints are smooth, without any crevices or grooves where debris or dirt can accumulate, reducing the risk of corrosion and damage to the cylinder.

-

- Customizable: Welded tee type cylinders can be customized to suit specific applications. The cylinders are available in different sizes and shapes, and they can be fabricated to meet the specific requirements of the application.

The customization process allows the cylinder to be optimized for performance, ensuring that it is suited for the intended application. This feature makes welded tee type cylinders ideal for use in various industrial applications, including construction, mining, and material handling.

-

- Cost-Effective: Welded tee type cylinders are cost-effective compared to other types of cylinders. The fabrication process used to manufacture these cylinders is simple, making it less expensive than other types of cylinders.

Furthermore, the high strength and durability of welded tee type cylinders reduce the need for frequent repairs and replacements, saving on maintenance costs. This feature makes them a popular choice for many industries, particularly those with a limited budget.

-

- Increased Efficiency: Welded tee type cylinders are highly efficient and effective. The design of the cylinder ensures that the force applied is transferred directly to the load, reducing energy loss and increasing efficiency.

The welded joints are strong and stiff, minimizing deflection and ensuring that the cylinder maintains its shape and structural integrity even under extreme conditions. This feature makes welded tee type cylinders ideal for use in applications requiring high efficiency and reliability.

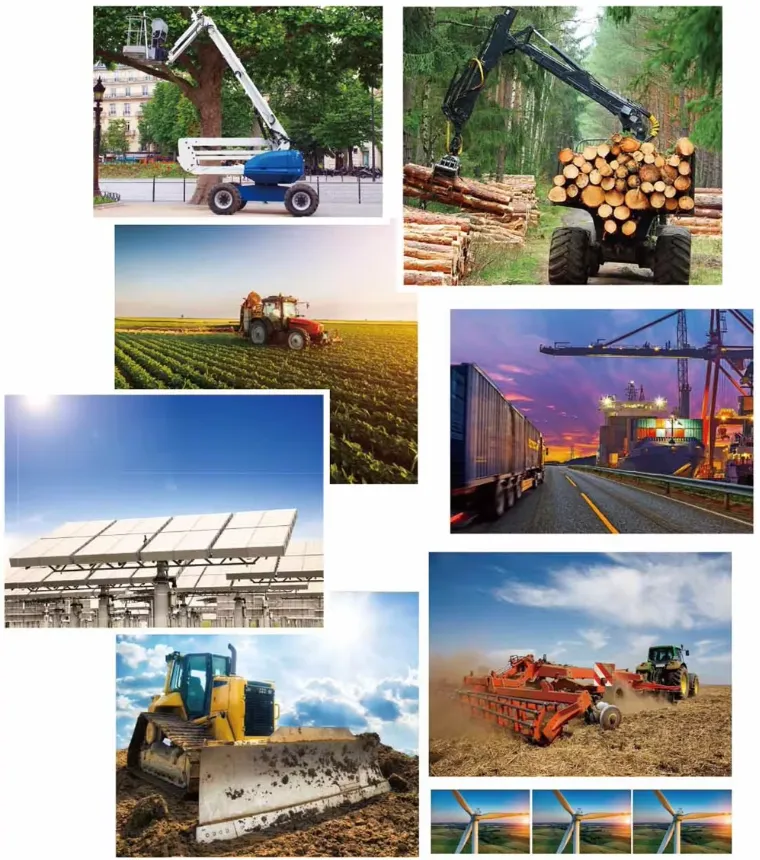

Application of Welded Tee Type Cylinder

-

Industrial Machinery and Equipment

Welded Tee Type Cylinder is widely used in industrial machinery and equipment, especially in hydraulic systems. The cylinder consists of a piston and a cylinder tube, which are welded together to form a single unit. This design offers several advantages over other types of cylinders, such as improved durability, higher strength, and greater precision.

One of the most important applications of Welded Tee Type Cylinder in industrial machinery is its ability to provide consistent and accurate force. This is essential for many manufacturing processes, where precise control is required to ensure the quality of the final product. Welded Tee Type Cylinder can also be used to regulate the flow of fluids in hydraulic systems, allowing for greater efficiency and reliability in a variety of industrial applications.

-

Agricultural Equipment

Welded Tee Type Cylinder is also commonly used in agricultural equipment, such as tractors and harvesters. These machines require powerful and reliable hydraulic systems to operate effectively, and Welded Tee Type Cylinder is an ideal choice for this purpose.

The cylinder’s rugged construction and high strength make it highly resistant to wear and tear, even in harsh operating conditions. This makes it an ideal choice for use in agricultural equipment, where durability is a key consideration. Welded Tee Type Cylinder can also be used to provide the precise control required for many agricultural processes, such as planting, harvesting, and irrigation.

-

Construction Equipment

Welded Tee Type Cylinder is also widely used in construction equipment, such as excavators, backhoes, and bulldozers. These machines require powerful and reliable hydraulic systems to perform heavy-duty tasks, such as digging, lifting, and pushing heavy loads.

Welded Tee Type Cylinder’s high strength and durability make it an ideal choice for use in construction equipment. Its ability to provide precise control and consistent force is essential for many construction processes, such as excavation, grading, and paving. Welded Tee Type Cylinder can also be used to regulate the flow of fluids in hydraulic systems, improving the efficiency and reliability of construction equipment in a variety of applications.

About FMP

FMP, established for over 30 years, is a professional manufacturer and supplier of various types of hydraulic cylinders, with our industrial area located in Italy. We have more than 100 pieces of equipment, including automatic gas shielded welding machines, deep hole boring machines, CNC lathes, cylindrical grinders, automatic cleaning machines, automatic installation machines, automatic hydraulic cylinder performance test benches, automatic painting lines, and more.

Our hydraulic cylinders undergo strict processing and inspection to ensure good quality for our customers. We offer a range of products, including hydraulic cylinder earrings, bidirectional automatic telescopic hydraulic cylinders, and more.

Our advantages:

- Design Service: Our experienced design team can assist with new product development or improvements to existing products to meet your needs.

- Product Service: We meticulously follow our production process, from raw materials to transportation, to ensure the highest quality products.

- Sample Process: We can develop samples to meet your specific needs and continuously modify them until we meet your requirements.

- R&D: We conduct research and development to study new market needs and develop new models when new cars are introduced to the market.

- Customization: We offer a range of customization options to meet your specific requirements.

At FMP, we are dedicated to providing high-quality hydraulic cylinders and exceptional customer service. Contact us today to find out how we can help with your hydraulic cylinder needs.

Author:CX