The Fundamentals of Planetary Gear Sets

Planetary gear sets, also known as epicyclic gear systems, are a cornerstone of modern mechanical engineering. At their core, these systems consist of a central sun gear, orbiting planet gears mounted on a carrier, and an outer ring gear. This unique arrangement allows planetary gear sets to deliver exceptional torque, speed reduction, and efficiency in a compact design. Whether you’re in Milan, Venice, Florence, or Bologna, industries across Italy rely on these robust systems for applications ranging from automotive transmissions to industrial machinery.

At FMP, we specialize in manufacturing high-quality planetary gear sets tailored to meet diverse needs. With a commitment to precision and innovation, we serve clients throughout Italy and beyond, ensuring top-tier performance in every gear we produce.

What Are Planetary Gear Sets?

A planetary gear set operates with three key components:

- Sun Gear: The central gear (often depicted in yellow) that drives the system.

- Planet Gears: Multiple gears (typically blue) that orbit the sun gear, mounted on a movable carrier (green).

- Ring Gear: An outer gear (pink) that meshes with the planet gears, enclosing the system.

This configuration allows for versatile gear ratios and high torque output, making planetary gear sets ideal for applications where space and weight are critical. From simple designs to complex compound systems, their adaptability suits a wide range of industries.

Applications of Planetary Gear Sets

Planetary gear sets are widely used across Italy, from the industrial hubs of Milan and Bologna to the engineering workshops of Florence and Venice. Their ability to provide significant speed reduction and torque in a compact form makes them essential in:

- Automotive and Off-Road Vehicles: Found in automatic transmissions and wheel drives.

- Industrial Machinery: Powering conveyors, mixers, and forestry equipment.

- Consumer Products: Used in electric screwdrivers and bicycle gear systems.

- Heavy Duty Applications: Supporting tractors, construction equipment, and turbine engines.

The load-sharing nature of multiple planet gears ensures durability and resistance to wear, a feature that Italian manufacturers and engineers in cities like Milan and Bologna particularly value for high-impact operations.

Why Choose Planetary Gear Sets?

The advantages of planetary gear sets are clear:

- High Torque Density: Multiple planet gears distribute the load, enhancing power output.

- Compact Design: Ideal for space-constrained applications.

- Durability: Even load distribution increases gear lifespan.

- Flexibility: Easily adjustable gear ratios by modifying the carrier or sun gear.

For businesses in Venice or Florence looking to optimize machinery performance, these benefits translate into efficiency and reliability, reducing downtime and maintenance costs.

FMP: Your Trusted Planetary Gear Set Manufacturer in Italy

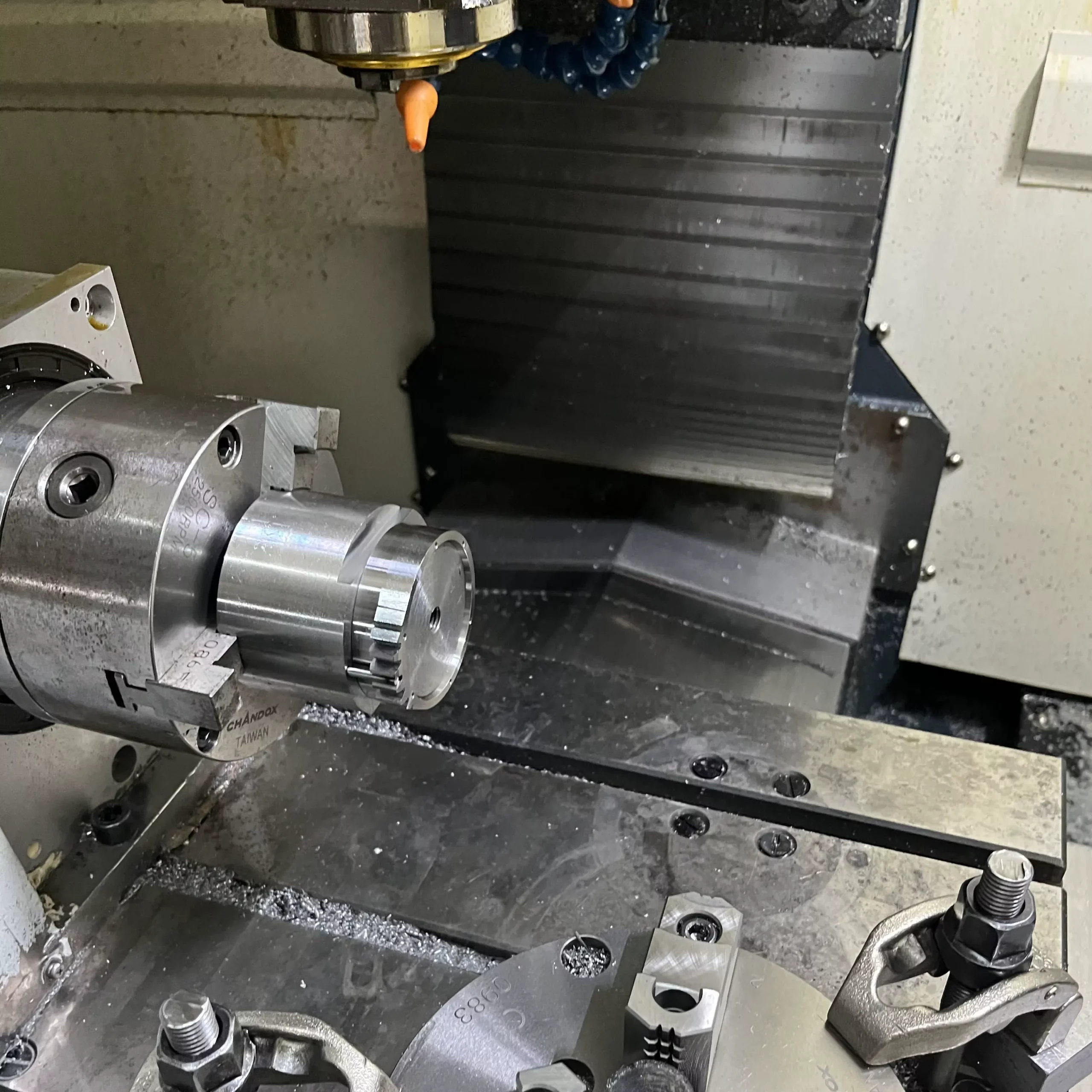

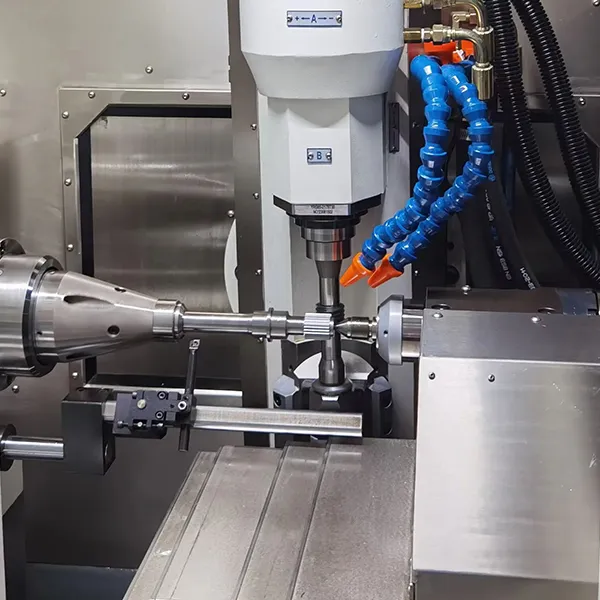

At FMP, we pride ourselves on being a leading producer of planetary gear sets, serving clients across Italy and globally. Based on our extensive engineering expertise, we offer:

- Variety of Types: From standard designs to complex compound systems, we manufacture planetary gear sets for all applications.

- Customization: Need a specific configuration? Our skilled engineers in Italy can design and produce custom planetary gear sets to meet your exact specifications.

- Precision Manufacturing: Using advanced techniques, we ensure every gear meets the highest standards of quality and performance.

Whether you’re in Milan’s bustling industrial sector, Venice’s innovative workshops, Bologna’s machinery hubs, or Florence’s artisanal engineering spaces, FMP is your go-to partner for planetary gear solutions.

|

|

|