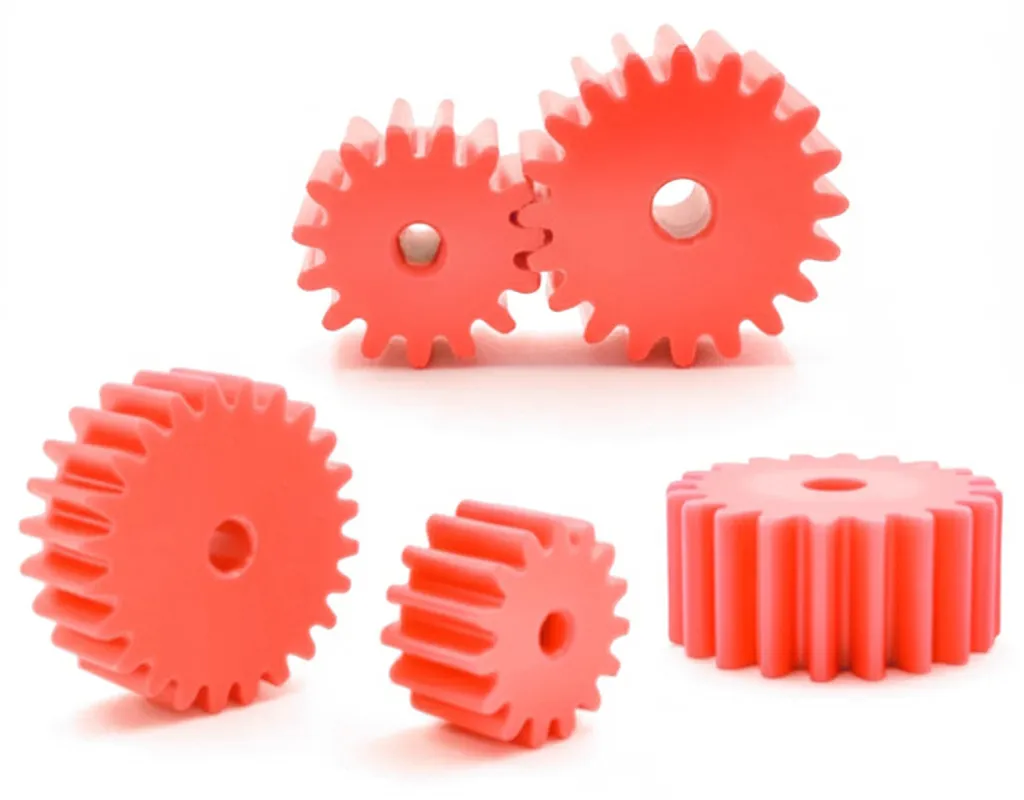

What Are Nylon Spur Gears?

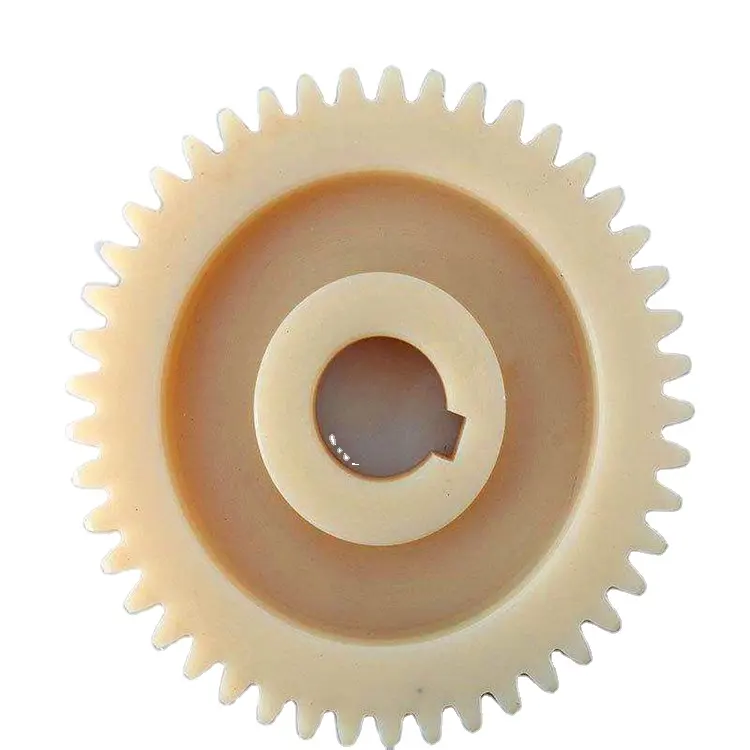

Nylon Spur Gears are a type of plastic gear widely used across industries for their exceptional properties. Made from engineering plastics like MC Nylon (a polyamide resin) and polyacetal (POM), these gears feature straight teeth on a cylindrical surface, making them ideal for transmitting motion and power between parallel shafts. Their importance spans industries such as food production, consumer electronics, chemicals, toys, and medical equipment, thanks to their lightweight design, rust-proof nature, and quiet operation.

Why Choose Nylon Spur Gears?

Key Advantages

- Lightweight: Compared to metal gears, Nylon Spur Gears significantly reduce the weight of machinery, enhancing efficiency.

- Rust-Proof: Unlike steel, nylon doesn’t corrode, making it perfect for humid or corrosive environments.

- Quiet Operation: Their inherent lubricity ensures smooth, noise-free performance, ideal for consumer electronics or medical devices.

- Self-Lubricating: Many nylon gears operate without additional lubrication when paired with metal gears, reducing maintenance costs.

- Cost-Effective: Injection molding allows for large-scale production at a lower cost.

Applications Across Italy

From food processing plants in Milan to toy manufacturing in Florence, and medical equipment production in Bologna, Nylon Spur Gears are a versatile choice. In Venice, where moisture resistance is key due to the humid climate, their non-rusting properties shine.

Materials Behind the Magic

FMP Company uses high-performance plastics like:

- MC Nylon: Known for enhanced strength and thermal stability, it’s a staple in our standard PS and PSA series.

- Acetal Copolymer (POM): A crystalline thermoplastic offering excellent chemical resistance and durability, used in our molded spur gears.

For demanding applications—such as those with large temperature fluctuations or heavy loads—we may incorporate metal hubs (e.g., S45C or stainless steel) fused or screwed to the nylon teeth, ensuring durability without sacrificing the benefits of plastic.

Mechanical and Thermal Properties

Here’s a snapshot of what makes these materials stand out:

| Property | MC Nylon | Acetal Copolymer |

|---|---|---|

| Tensile Strength | High | Moderate |

| Thermal Expansion | 9×10⁻⁵ /°C | Lower than Nylon |

| Chemical Resistance | Excellent | Excellent |

| Water Absorption | Higher | Lower |

Note: MC Nylon data is based on dry conditions; strength decreases with temperature rises or moisture absorption.

Dimensional Change Example

Consider a MC Nylon gear rack (1010 mm long) at 20°C. If the temperature rises to 40°C:

- Coefficient of Linear Expansion: 9×10⁻⁵ /°C

- Calculation: Dimensional Change = 9×10⁻⁵ × 1010 mm × 20°C = 1.818 mm

This elongation highlights the need to account for thermal and moisture effects in design—a consideration FMP’s engineers expertly handle.

FMP Company: Your Nylon Spur Gear Experts

At FMP Company, we specialize in manufacturing a wide range of Nylon Spur Gears to meet diverse needs across Italy and beyond. Our offerings include:

- DSL Series: Easy fastening for gears and axes.

- NSU & PU Series: Nylon teeth with metal cores for enhanced strength and machining ease.

- PS & PSA Series: Standard MC Nylon options, with PSA featuring a boss-free design.

- DS Series: Cost-effective, low-strength gears via injection molding.

Custom Solutions

Can’t find the model you need in our catalog? No problem! FMP Company excels in custom orders. Whether you’re in Milan designing consumer electronics or in Venice crafting chemical equipment, we’ll manufacture gears tailored to your specifications. If a model isn’t listed, it simply means we haven’t uploaded it yet. Email us at info@fmpcomponents.it with your requirements, and our engineers will respond within 24 hours with a solution.

|

|

|