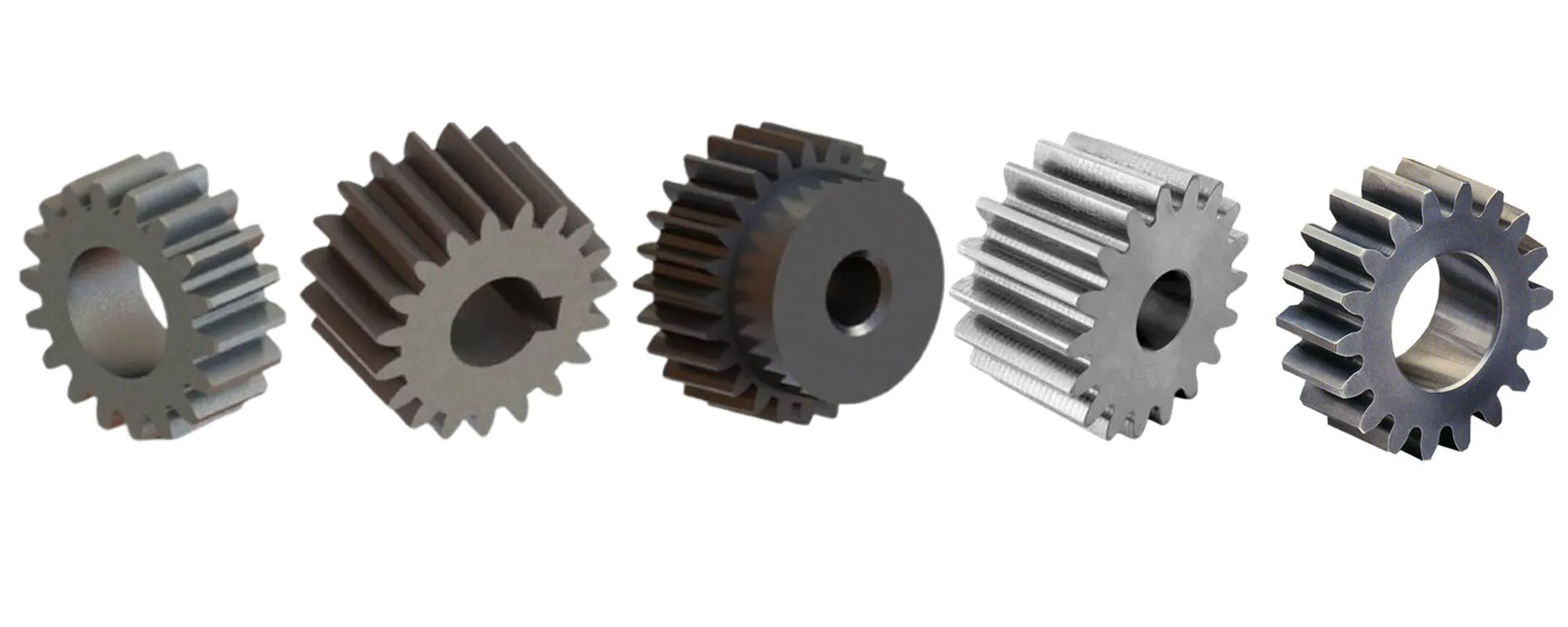

Forging Spur Gears: Precision Manufacturing by FMP Company for Italy and Beyond

When it comes to producing high-quality spur gears, forging remains a time-honored and advanced manufacturing technique. At FMP Company, we specialize in crafting forging spur gears that meet the diverse needs of industries across Italy—from Milan’s automotive hubs to Venice’s engineering workshops, Florence’s machinery innovators, and Bologna’s industrial powerhouses. We deliver near-net or net-shape spur gears that require minimal finishing, ensuring strength, durability, and efficiency for applications in automotive, aerospace, agriculture, energy, and more.

What Are Forged Spur Gears?

Forged spur gears are created through a meticulous die-forging process where heated metal billets—such as low-alloy steel, brass, aluminum alloys, stainless steel, titanium, or heat-resistant alloys—are shaped under intense pressure using specialized dies. This process compresses the metal grain, resulting in gears with exceptional fatigue resistance and load-carrying capacity. Unlike cut gears, forged spur gears feature a contoured grain flow that follows the tooth profile, enhancing strength without increasing size. At FMP, we use techniques like closed-die forging and high-energy-rate forging (HERF) to produce gears that meet stringent tolerances and surface finish standards.

The Forging Process at FMP

At FMP Company, our forging process is engineered to deliver precision, efficiency, and durability, catering to a wide range of industries—including heavy machinery applications across Italy and beyond. Whether it’s a compact spur gear for automotive use or a massive 600 mm diameter 40CrMn forged spur gear for ball mills, our advanced techniques ensure top-tier quality. Here’s how we bring our forged spur gears to life:

- Gear Blank Heating: We heat metal billets to precise temperatures—such as 1230°C for 8620 steel or tailored ranges for 40CrMn—to enhance workability and ensure uniform forging. This step is critical for achieving the strength required in heavy-duty gears.

- Die Forging: Utilizing state-of-the-art presses and high-energy-rate forging (HERF), we shape billets into near-net forms with minimal strikes. High-speed rams deliver forces like 353,000 J to forge a 4.5 kg spur gear from a 75 mm 8620 steel billet in one blow, or up to 271,000 J for an 11 kg automotive flywheel made from grade 40 gray cast iron.

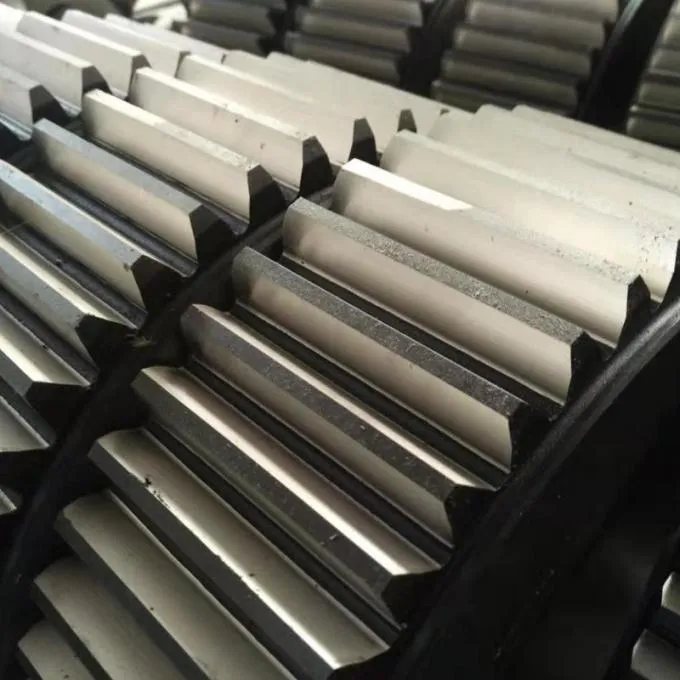

- Trimming and Finishing: Excess material is expertly trimmed, and gears are refined to exact specifications. For standard gears, we leave 0.13–0.51 mm of stock for final machining, while heavy-duty components like our 600 mm 40CrMn spur gears for ball mills are forged to near-finished dimensions with tolerances as tight as +0.00/-0.18 mm.

Forging for Heavy Machinery

Beyond standard applications, FMP excels in producing forged spur gears for heavy machinery. Take our 40CrMn forged spur gear as an example: with a diameter of 600 mm, this robust component is designed specifically for ball mills used in mining and industrial processing. Forged from high-strength 40CrMn steel, it offers exceptional durability and wear resistance, making it ideal for demanding environments. Manufactured in Luoyang, this gear comes with a minimum order quantity of 10 pieces, packaged in sturdy wooden crates, and delivered within 25 working days. With a supply capacity of 10,000 pieces and a maximum forging weight of 40 tons, FMP is equipped to meet the needs of Italy’s heavy industries—from Milan’s manufacturing plants to Bologna’s mining equipment suppliers.

|

|

|

|

|

Technical Excellence in Every Gear

Our capabilities extend to large-scale gear shafts and custom forgings, such as our tailored large-module spur gear shafts made from materials like 35#, 45#, 40Cr, or 42CrMo. These components, with diameters up to 1850 mm and lengths reaching 12 meters, are widely used in transmissions, speed variations, and rotary systems for civil and industrial equipment. With a machining precision of 0.01 mm and rigorous testing (ultrasonic, magnetic, tensile, and penetration), we ensure every gear meets international standards like DIN, GB, and ISO.

Real-World Examples

- A 4.5 kg spur gear forged from 8620 steel achieves a near-net shape with a final-thickness web and minimal tooth stock, ready for finishing in applications like automotive transmissions.

- An 11 kg automotive flywheel, forged from grade 40 gray cast iron at 955°C with 271,000 J, meets tight tolerances for immediate use.

- Our 600 mm 40CrMn spur gear, built for ball mills, showcases our ability to forge large, high-performance gears for heavy machinery, with surface treatments like quenching or polishing available upon request.

At FMP, we combine precision forging with the ability to handle heavy-duty demands, ensuring our gears deliver unmatched reliability and performance.

|

|