Double helical gears, often referred to as herringbone gears, represent a pinnacle of engineering ingenuity in gear technology. These gears combine the strengths of helical gears—such as smooth operation and high load capacity—with a unique design that eliminates axial thrust, making them indispensable in demanding industrial applications. At FMP Company, we specialize in manufacturing a wide range of double helical gears tailored to meet diverse needs across Italy, from the industrial hubs of Milan and Bologna to the engineering centers of Florence and Venice.

Double helical gears, often referred to as herringbone gears, represent a pinnacle of engineering ingenuity in gear technology. These gears combine the strengths of helical gears—such as smooth operation and high load capacity—with a unique design that eliminates axial thrust, making them indispensable in demanding industrial applications. At FMP Company, we specialize in manufacturing a wide range of double helical gears tailored to meet diverse needs across Italy, from the industrial hubs of Milan and Bologna to the engineering centers of Florence and Venice.

What Are Double Helical Gears?

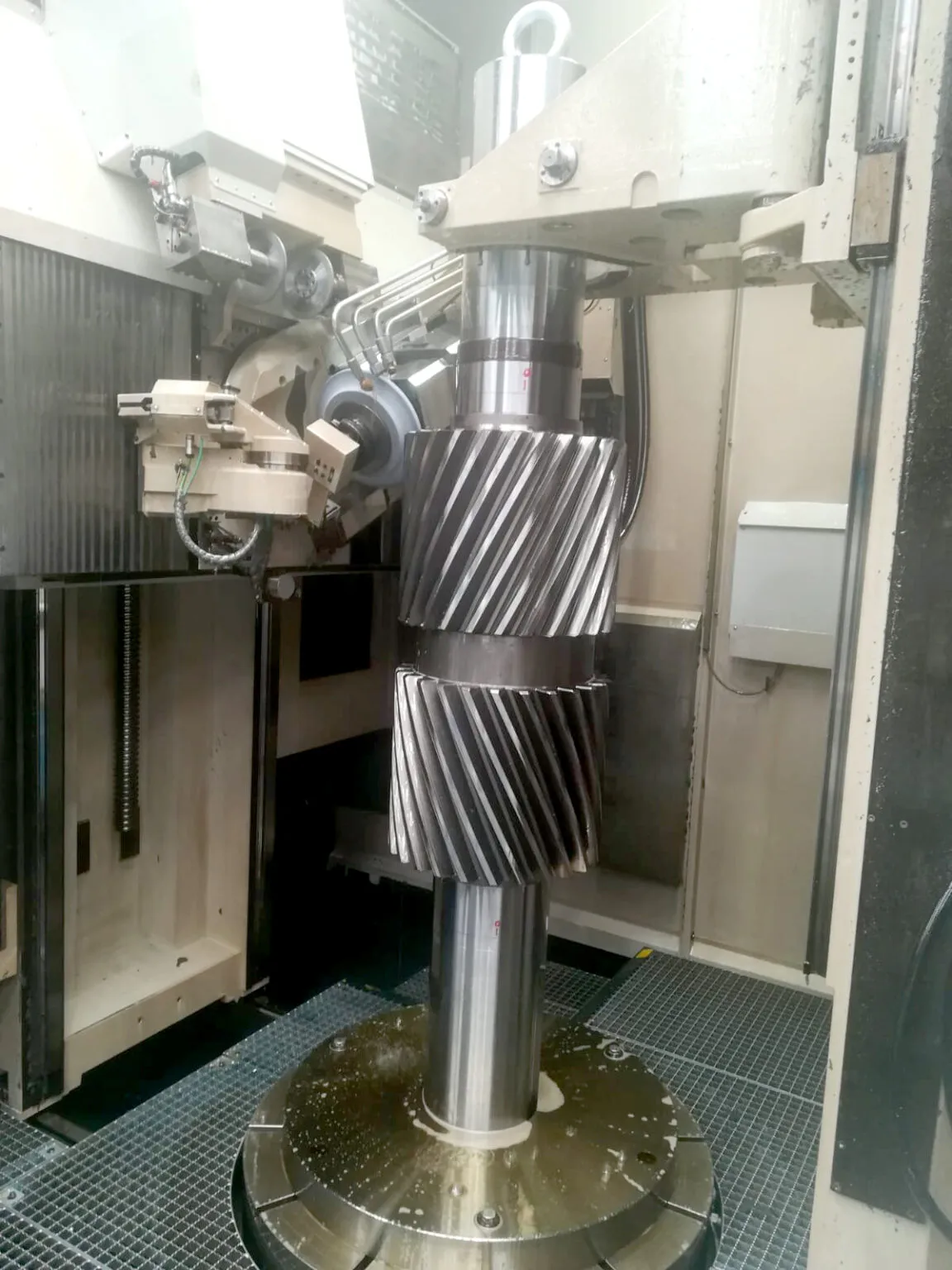

Double helical gears consist of two sets of helical teeth—one with a left-hand twist and the other with a right-hand twist—arranged symmetrically on a single gear. This “V”-shaped configuration distinguishes them from single helical gears and herringbone gears, the latter lacking a central groove. The opposing helix angles cancel out axial forces, ensuring smoother, quieter operation and reduced wear on bearings. Whether you’re in Milan seeking precision gears for turbomachinery or in Venice looking for marine propulsion components, double helical gears offer unmatched reliability.

Design and Structure

The hallmark of a double helical gear is its dual-helix design:

- Helix Angle: The left- and right-hand helices have identical angles but opposite orientations, neutralizing axial thrust.

- Central Gap: Unlike herringbone gears, double helical gears feature a small groove between the helices, aiding manufacturing and assembly.

- Tooth Engagement: The overlapping teeth provide a higher contact ratio, distributing loads evenly and enhancing durability.

This design ensures optimal performance in high-torque applications, a feature appreciated by engineers in Bologna’s heavy machinery sector and Florence’s aerospace industry.

|

|

How Double Helical Gears Work

Double helical gears transmit rotational motion between parallel shafts with exceptional efficiency. The simultaneous engagement of opposing helical teeth balances axial forces, eliminating the need for additional thrust bearings—a significant advantage over single helical gears. This results in reduced vibration and noise, making them ideal for high-speed operations in Italy’s thriving industrial cities like Milan and Turin.

Advantages of Double Helical Gears

Double helical gears offer numerous benefits:

- High Load Capacity: Perfect for heavy-duty applications in Bologna’s mining and steel industries.

- Quiet Operation: Smooth tooth engagement minimizes noise, a key factor for Florence’s precision manufacturing.

- No Axial Thrust: The balanced design extends bearing life, reducing maintenance costs in Venice’s marine sector.

- Enhanced Efficiency: Continuous tooth contact boosts torque transmission, optimizing energy use.

- Durability: Even load distribution ensures longevity, vital for Milan’s power generation plants.

- Compact Design: High performance in a smaller footprint suits space-constrained applications.

These advantages make double helical gears a preferred choice across Italy’s diverse industrial landscape.

Applications of Double Helical Gears

Double helical gears excel in various sectors:

- Heavy Machinery: Used in crushers and conveyors in Bologna’s industrial zones.

- Power Generation: Integral to turbine gearboxes in Milan’s energy facilities.

- Oil and Gas: Essential for drilling systems in offshore platforms near Venice.

- Automotive and Aerospace: High-torque transmissions in Florence’s engineering hubs.

- Marine Propulsion: Powering ships along Italy’s coastal cities like Genoa and Venice.

FMP Company: Your Partner in Double Helical Gear Solutions

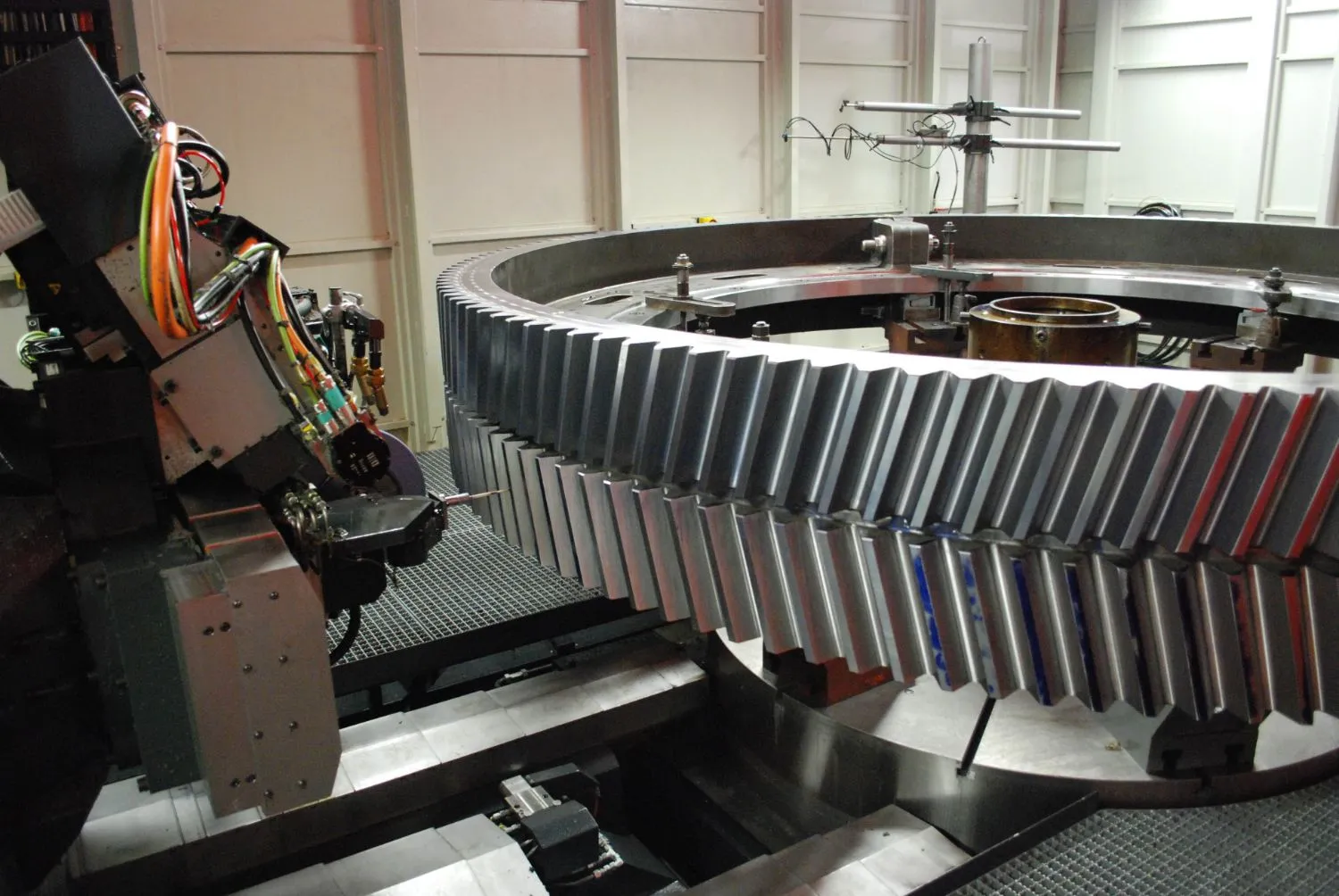

We produce double helix crown wheels and shafts up to Ø 2,000 mm. Optimum corrections in terms of tooth profile crown, tooth tip and root finishing as well as root radius ensure smooth, quiet running with optimum drive noise characteristics

At FMP Company, we pride ourselves on producing a wide variety of double helical gears, from standard models to close-gap designs, helical gears, spur gears, internal gears, and pinions. Based in Italy, we serve clients in Milan, Venice, Florence, Bologna, and beyond, delivering precision-engineered solutions for every project.

- Custom Gears: Need a specific design? We offer fully customized double helical gears tailored to your requirements, whether for aerospace in Florence or marine applications in Venice.

- Extensive Range: Our product lineup includes double helical gears up to 8 meters in diameter, crafted with advanced machinery and high-strength steels to withstand rugged environments.

- Not in Our Catalog?: If you don’t find the model you need in our product list—whether in Milan or Bologna—it’s likely we haven’t uploaded it yet. Simply email us at info@fmpcomponents.it with your specifications, and our engineers will respond within 24 hours with a solution.

|

|

|

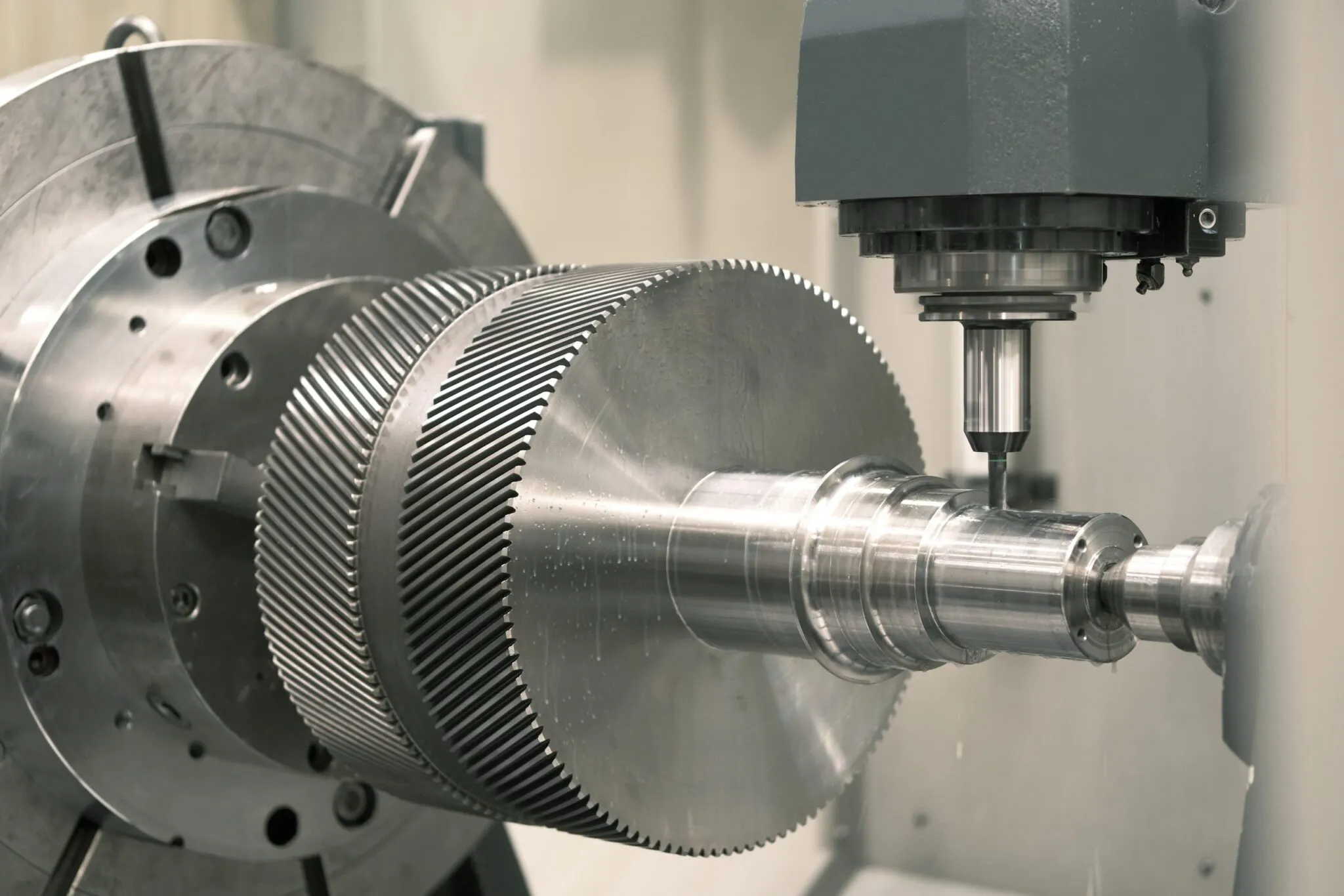

Optimized Manufacturing for Italian Markets

FMP leverages cutting-edge technology, including FE-based tooth contact analysis and continuous generating grinding, to ensure precision and quality. Our gears meet AGMA quality 12 standards, offering superior performance for industries in Turin, Genoa, and beyond. Whether you’re optimizing power density in Milan’s turbo gear units or reducing noise in Florence’s electromobility projects, FMP delivers.

Double helical gears are a cornerstone of modern engineering, blending strength, efficiency, and quiet operation. At FMP Company, we’re committed to providing Italy’s industrial leaders—from Milan to Venice—with top-tier gear solutions. Whether you need off-the-shelf products or bespoke designs, contact us today. If your desired model isn’t listed, don’t hesitate to email us—our team is ready to assist within 24 hours. Let FMP power your next project with precision and reliability.