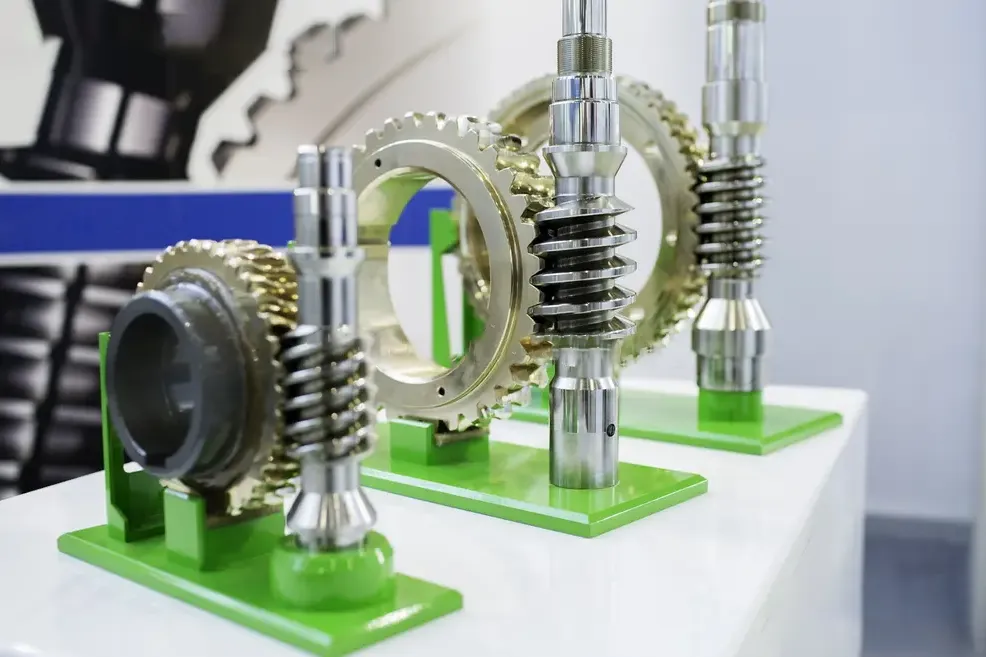

A Cylindrical Worm Wheel is a key component in worm gear systems, designed to mesh seamlessly with a worm to transmit power efficiently while maintaining smooth operation and high torque capacity. At FMP Company, we specialize in producing a diverse range of Cylindrical Worm Wheels, available in various types and specifications to suit your specific applications, with customization options also offered. If you can’t locate the exact model you need in our product list, it’s likely we haven’t updated it yet—please reach out to us via email with your requirements, and our expert engineers will respond within 24 hours to assist you.

Features of Cylindrical Worm Wheel

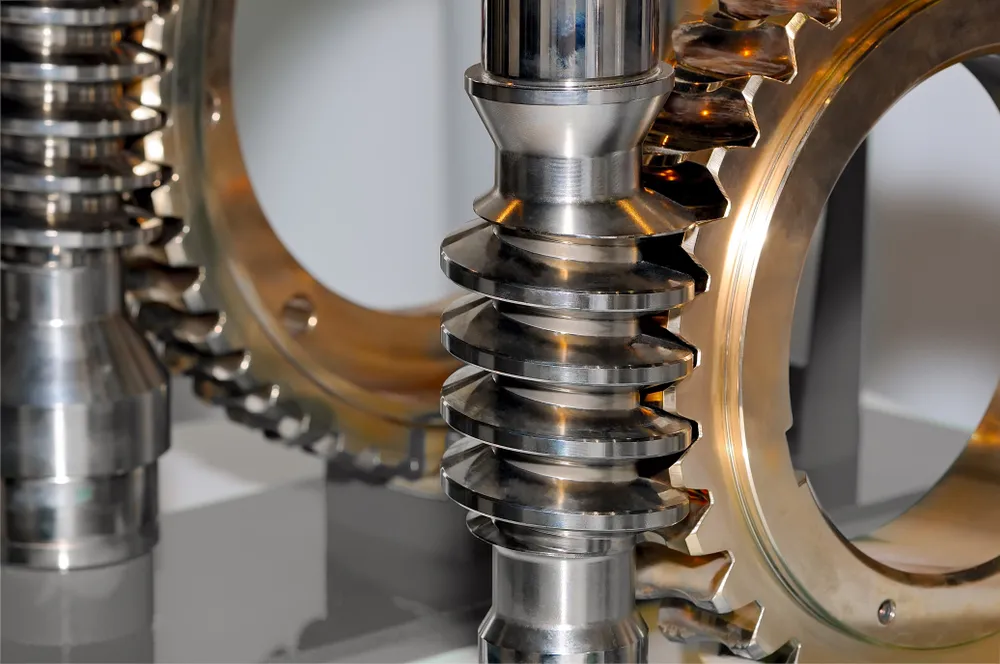

Cylindrical worm wheels are integral to worm gear systems and come in two primary configurations: a “worm and helical gear” set and a “worm and worm wheel” set. The first type, a subset of helical gears for crossed shafts, features a pinion with a minimal number of teeth (e.g., 1, 2, or 3) and a pronounced helix angle, calculated similarly to standard helical gears using normalized standard modules. However, due to point contact between tooth flanks, this setup is less suitable for high-load applications. In contrast, the “worm and worm wheel” configuration involves worm wheels milled with a worm mill matching the worm’s specifications, enabling line contact between teeth and supporting higher tooth forces for greater load capacity.

Additional design features enhance functionality. When the worm bearing’s oil immersion meets requirements but the worm’s depth is insufficient, an oil splashing ring can be added to the worm shaft. This ring lubricates transmission components and bearings, preventing excessive oil immersion of the worm bearing. For high-speed applications where the worm’s peripheral speed (PI) exceeds 10 m/s, the worm wheel is replaced with an overhead-type worm gear positioned above the worm. This arrangement reduces gear speed, minimizes oil agitation losses, and lowers the risk of impurities or abrasives in the oil pool entering the meshing area, ensuring reliable performance.