Bucket Elevator Sprocket

The bucket elevator is designed to efficiently transport materials from lower to higher elevations.  After materials are placed into the hopper via a vibration table, the machine operates automatically and continuously, lifting the materials upward. The speed of the conveyor can be adjusted based on the required transport volume, and the lifting height can be customized to suit specific needs.

After materials are placed into the hopper via a vibration table, the machine operates automatically and continuously, lifting the materials upward. The speed of the conveyor can be adjusted based on the required transport volume, and the lifting height can be customized to suit specific needs.

Our bucket elevator features a self-designed PP non-toxic hopper, which broadens its application in various industries. The hopper is carefully engineered for optimal performance, ensuring durability and safe handling of materials. All dimensions of the system are tailored to meet the specific requirements of the application.

This bucket elevator is ideal for supporting vertical packaging machines and computer metering systems. It is widely used in the lifting and feeding of products such as food, pharmaceuticals, industrial chemicals, screws, nuts, and other items. The machine’s operation can be automatically controlled through signal recognition from the connected packaging machine, allowing for seamless start and stop functionality.

With its flexible design and high-quality components, our bucket elevator is a reliable solution for efficient vertical transportation in diverse industries.

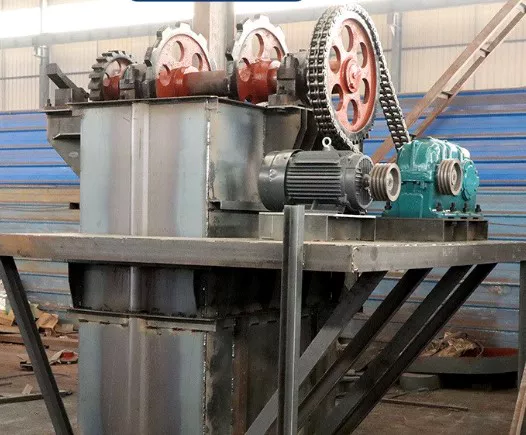

Working Principle of Bucket Elevator

The bucket elevator operates by using a series of hoppers to scoop materials from a lower storage area. As the conveyor belt or chain is lifted, it passes over the top wheel, then descends to discharge the materials into a receiving tank. This process allows the bucket elevator to transport materials vertically in a continuous motion.

In most bucket elevators, the drive system is powered by a rubber belt, which is installed on both the lower and upper drive drums, as well as the upper and lower steering drums. Alternatively, chain-driven bucket elevators are equipped with two parallel transmission chains. These chains work in conjunction with a pair of transmission sprockets at either the top or bottom, along with steering sprockets located at the opposite end.

In most bucket elevators, the drive system is powered by a rubber belt, which is installed on both the lower and upper drive drums, as well as the upper and lower steering drums. Alternatively, chain-driven bucket elevators are equipped with two parallel transmission chains. These chains work in conjunction with a pair of transmission sprockets at either the top or bottom, along with steering sprockets located at the opposite end.

To ensure efficient and clean operation, bucket elevators are typically enclosed in casings, which help to prevent dust from escaping during material transport.

Bucket elevators are ideal for vertical transportation of materials. Once the materials are placed into the hopper via a vibration table, the system runs automatically and continuously to lift the materials to the desired height, providing reliable and efficient material handling.

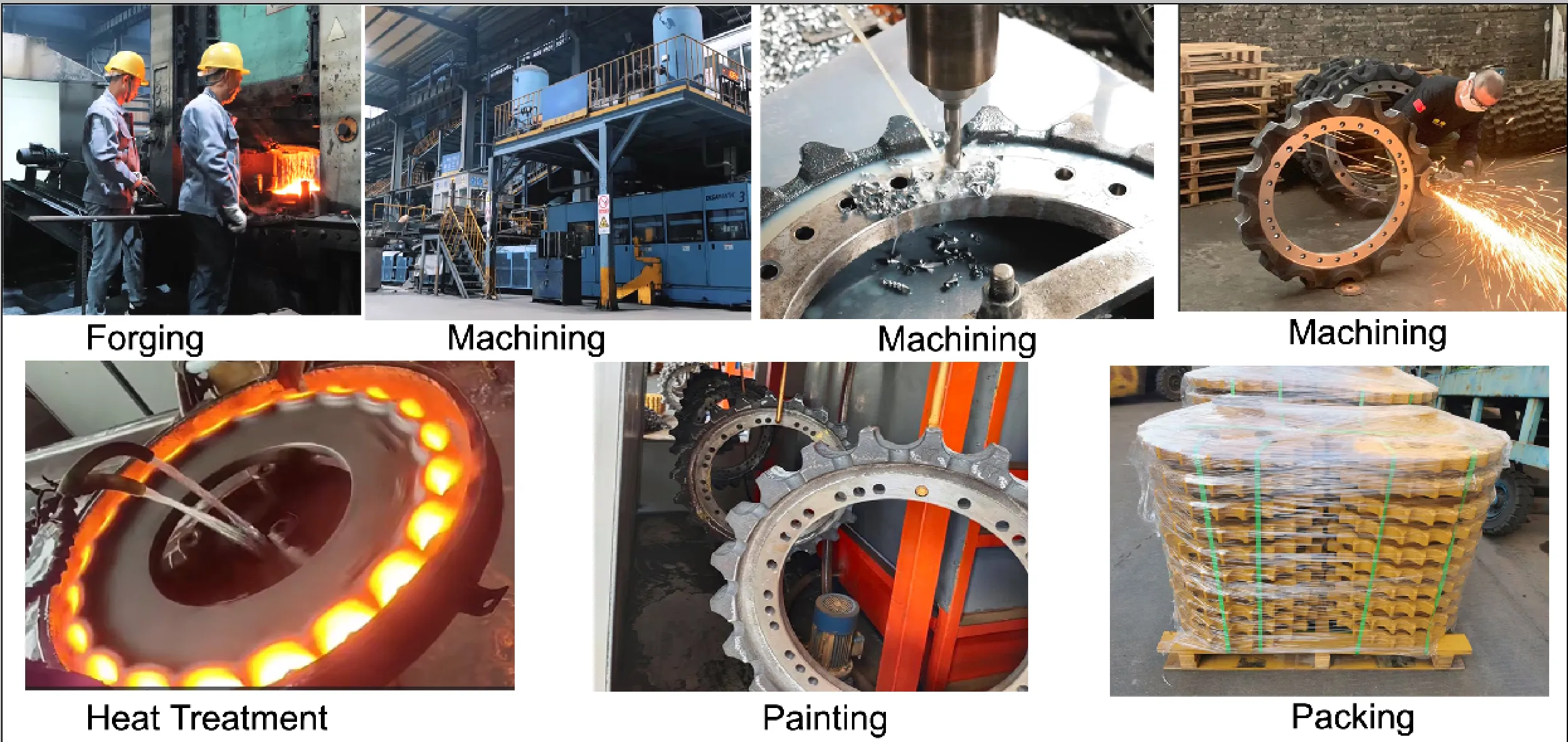

About FMP

At FMP, we pride ourselves on being a leading manufacturer of high-quality sprockets, produced in our advanced facility in Italy. We offer a diverse range of sprockets designed to meet the unique needs of various industries. Whether you’re looking for finished bore sprockets, idler sprockets, taper lock sprockets, or conveyor sprockets, we craft each product with precision and durability to ensure optimal performance. Our selection includes stainless steel, plastic, and steel sprockets, as well as specialized models like double pitch and double row sprockets, allowing us to provide the ideal solution for any application.

What sets FMP apart is our dedication to customization. We recognize that every project has its own specific requirements, which is why we offer bespoke sprocket solutions tailored to your exact needs. Whether you require a custom design or have specialized technical demands, our expert team is ready to deliver precise, reliable, and high-performance solutions.

We are committed to excellence in both engineering and manufacturing, ensuring that each sprocket we produce meets the highest quality standards and is built to last. If you have any inquiries or need a customized sprocket solution, don’t hesitate to contact us. Our team is here to provide you with expert guidance and timely responses to ensure your complete satisfaction. Simply reach out via email, and we will get back to you as soon as possible.