Specifications of Manure Spreader Gearbox TB-19C (1:1.46)

|

|

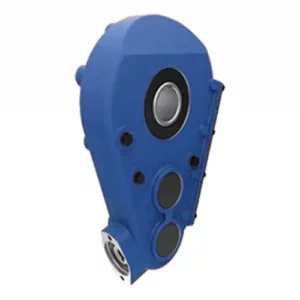

| Product Description |

Manure Spreader Gearboxes – Replacement of Comer Gearbox TB-19C 1:1.46

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Max. output torque |

42.3 daNm

|

| Contains oil |

No

|

| Gear arrangement Increasing |

25 – 26 – 27 – 28

|

| Gear arrangement Reducing |

5 – 6

|

| Input power kW / HP Increasing |

20.6 / 28 kW/HP

|

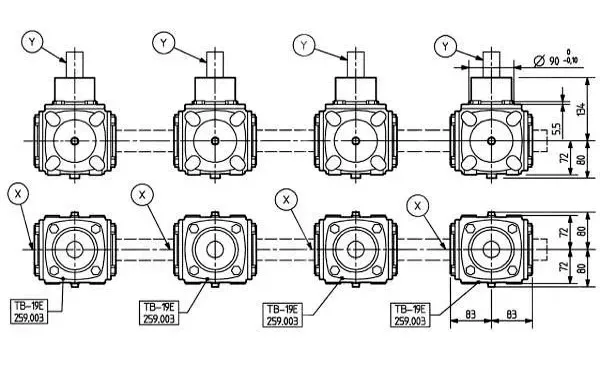

| Input shaft Increasing |

X – Y

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

16.9 / 23 kW/HP

|

| Output Torque DaNm Increasing |

24.1 daNm

|

| Ratio Increasing |

1: 1.46

|

| Ratio Reducing |

1.46: 1

|

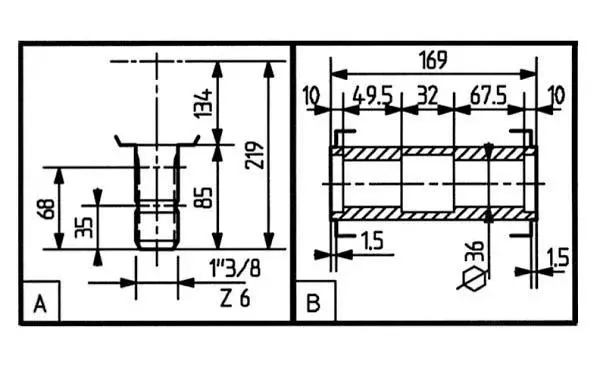

| Shaft X |

SW 36 (B)

|

| Shaft Y |

SW 36 (B)

|

| Shaft Z |

1 3/8″ (6) (A)

|

Advantages of Manure Spreader Gearbox TB-19C (1:1.46)

- High-Performance Gear Ratio:

The TB-19C gearbox offers a 1:1.46 gear ratio, which ensures optimal power transmission for manure spreading operations. This provides improved torque for better material flow and efficient spreading, particularly in challenging agricultural conditions. - Durable Construction:

Built with robust materials, the TB-19C gearbox is designed to withstand the rigors of heavy-duty agricultural work. Its high-strength construction ensures reliability, even in harsh environments, making it ideal for long-term use in manure spreading equipment. - Precision Engineering:

Precision-machined components ensure a perfect gear mesh and proper bearing preload, contributing to smoother operation, reduced wear, and longer lifespan. The well-engineered design of the TB-19C minimizes the risk of mechanical failure, offering a more dependable solution for farmers. - Corrosion and Wear Resistance:

The gearbox is designed to resist corrosion and wear, even when exposed to harsh, wet, and chemically aggressive conditions typical in manure spreading. This significantly extends the gearbox’s service life and reduces maintenance needs. - Efficient Power Transmission:

The TB-19C gearbox effectively transmits power from the tractor’s PTO to the manure spreader, ensuring efficient material distribution. The 1:1.46 ratio optimizes performance while maintaining low energy consumption, reducing the load on the tractor.

In summary, the TB-19C Manure Spreader Gearbox (1:1.46) offers superior performance, durability, and efficiency. With its precision engineering, corrosion resistance, and low maintenance requirements, it enhances the functionality of manure spreaders, ensuring high-quality operation and extended lifespan for agricultural operations.

Applications of Manure Spreader Gearbox TB-19C (1:1.46)

The Manure Spreader Gearbox TB-19C (1:1.46) is specifically engineered for manure spreading equipment, offering excellent performance and durability for various agricultural tasks. Below are some of the key applications for this versatile gearbox:

- Manure Spreading:

The primary application of the TB-19C gearbox is in manure spreaders. Its precise gear ratio of 1:1.46 ensures the efficient transfer of power from the tractor’s PTO to the spreader, optimizing the uniform distribution of manure over fields. This contributes to better soil health and crop yields. - Slurry Spreading:

The TB-19C is also well-suited for slurry spreading systems, which often require high torque for proper material flow. Its robust design handles the challenges of slurry spreading, ensuring a consistent and efficient application of liquid manure. - Fertilizer Spreaders:

While primarily designed for manure spreaders, the TB-19C gearbox can be used in fertilizer spreaders as well. The gearbox’s efficient power transmission and smooth operation make it a reliable choice for spreading granular fertilizers over large fields, ensuring even distribution. - Compost Spreaders:

For composting operations, the TB-19C gearbox can be integrated into compost spreaders. Its precision and durability allow for the spreading of compost evenly across the field, enhancing soil fertility and promoting healthier plant growth. - Lime and Sand Spreaders:

The gearbox is adaptable to lime and sand spreaders, where uniform distribution is critical. The TB-19C’s high-performance gearing and reliability under heavy loads help in consistent application of materials for soil conditioning and other agricultural needs.

In conclusion, the TB-19C (1:1.46) gearbox is a versatile and reliable solution for a wide range of agricultural spreading applications, ensuring efficient, uniform, and cost-effective distribution of various organic and inorganic materials in the field. Its robust construction and precise engineering make it a valuable component in any farming operation that requires consistent power transmission and durability.

Agricultural PTO Shaft and Manure Spreader Gearbox

In agricultural operations, efficient power transmission and reliable equipment are essential for performing various tasks such as manure spreading. Two crucial components that ensure smooth operations in these applications are the Agricultural PTO Shaft and the Manure Spreader Gearbox. Together, they provide the necessary mechanical power for spreading manure and other materials over fields, contributing to better soil fertility and crop production. Here’s a breakdown of their roles and how they work together:

How PTO Shaft and Manure Spreader Gearbox Work Together

- Power Transfer from Tractor to Equipment:

- The PTO shaft connects to the tractor’s PTO output, transferring mechanical power to the manure spreader’s gearbox.

- Gearbox Role:

- The manure spreader gearbox receives this rotational power from the PTO shaft. It regulates the speed and torque of the power transmitted to the manure spreader’s moving components, such as the spreader blades or auger.

- Even Distribution of Manure:

- The gearbox ensures that the manure spreader operates at the correct speed and torque, ensuring even and consistent distribution of manure across the field for optimal soil enrichment.

- Efficient Use of Power:

- The combination of the PTO shaft’s power transmission and the gearbox’s torque adjustment allows for the efficient use of tractor power. This maximizes productivity while reducing fuel consumption and wear on both the tractor and spreading equipment.

Benefits of Using Agricultural PTO Shafts and Manure Spreader Gearboxes

- Increased Efficiency: Proper coordination between the PTO shaft and manure spreader gearbox optimizes the spreading process, reducing labor and time required for field tasks.

- Improved Soil Health: Even and accurate manure distribution leads to better soil fertility, promoting healthier crop growth.

- Reduced Equipment Wear: The efficient transmission of power minimizes strain on both the tractor and spreading equipment, prolonging the lifespan of the machinery.

- Enhanced Precision: Adjustable gear ratios in the gearbox allow operators to fine-tune the spreading process to meet the specific needs of different fields and crops.

- Cost-Effective: Efficient use of power reduces energy consumption and operational costs, making the equipment more cost-effective over time.

The Agricultural PTO Shaft and Manure Spreader Gearbox work in tandem to ensure efficient, reliable, and uniform manure spreading. Together, they provide the necessary power and precision for agricultural machinery, ensuring that manure, fertilizers, and other organic materials are applied correctly, improving soil fertility and overall farm productivity. Whether in large-scale commercial farming or small family operations, this combination of components plays a crucial role in modern agriculture.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer known for its exceptional expertise in designing, developing, and producing high-performance gearboxes, with a strong focus on the agricultural machinery sector. Renowned for precision engineering, innovative solutions, and a consistent track record of reliability, FMP has earned a trusted reputation across both agricultural and industrial markets. Our diverse product portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and other essential components, each tailored to meet the specific requirements of a wide range of applications.

At FMP, we understand that each client faces unique challenges, and this understanding drives our commitment to providing tailored solutions. Whether developing individual components or designing complete, integrated systems, we work closely with our clients to ensure that each solution not only meets their immediate needs but also optimizes performance and maximizes overall value. Our dedication to timely, professional responses and expert guidance ensures that every inquiry is addressed with precision, consistently achieving optimal results.

We prioritize clear and continuous communication throughout the entire product development cycle. Our dedicated team collaborates closely with clients to gain an in-depth understanding of their requirements, offering valuable insights and practical recommendations to achieve the best outcomes. Whether we’re developing innovative products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to consistently exceed client expectations by providing exceptional service and delivering outstanding results with every project.

At the heart of FMP’s operations lies an unwavering commitment to quality. We adhere to the highest manufacturing standards and implement rigorous quality control processes to ensure that every product meets, and often surpasses, industry benchmarks. This dedication to excellence, combined with our core values of integrity, teamwork, and perseverance, has enabled us to establish long-lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is dedicated to fostering global partnerships by offering expert advice and customized solutions that evolve with the ever-changing needs of our clients. We aim to build long-term, mutually beneficial relationships that contribute to the ongoing success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an established system, FMP is ready to help you navigate technical challenges and ensure your continued success.

Author: CX