The Ningbo Bridge Split-Type Steering Cylinder is a high-quality product designed for efficient steering and control in various applications. With its innovative split-type design, this steering cylinder offers enhanced durability and ease of maintenance.

Featuring advanced technology and precision engineering, the Ningbo Bridge Split-Type Steering Cylinder ensures smooth and accurate steering performance. It is built to withstand harsh conditions and heavy usage, making it suitable for use in industries such as automotive, marine, and agriculture.

This steering cylinder is easy to install and compatible with a wide range of vehicles and machinery. Its compact size and lightweight design make it convenient for integration into different systems. The high-quality materials used in its construction guarantee longevity and reliability.

Key features of the Ningbo Bridge Split-Type Steering Cylinder include:

1. Split-type design for easy maintenance and repair.

2. Smooth and precise steering performance.

3. High durability and resistance to wear and tear.

4. Suitable for various applications and industries.

5. Easy installation and compatibility with different vehicles and machinery.

6. Compact size and lightweight design for easy integration.

In conclusion, the Ningbo Bridge Split-Type Steering Cylinder is a top-notch product that provides reliable and efficient steering control. Its innovative design, durability, and compatibility make it an excellent choice for different industries and applications.

The steering hydraulic cylinder is a crucial component in modern power steering systems. It utilizes hydraulic fluid to make steering effortless, especially in larger vehicles or during low-speed maneuvers. Working in tandem with the steering rack, this component enables smooth, responsive handling that enhances driving comfort and control.

Vehicle owners must understand the proper usage, maintenance, and functionality of the steering hydraulic cylinder. Regular inspections and timely maintenance promote a safer driving experience and extend the hydraulic cylinder’s lifespan. Investing in your vehicle’s steering system today guarantees a smoother, more controlled ride, and the confidence that comes with knowing your steering is in top condition.

Steering Hydraulic Cylinder Parameter:

| Cylinder Diameter (mm) | Rod Diameter (mm) | Travel (mm) | Installation Distance (mm) | Image |

|---|---|---|---|---|

| 63 | 40 | 265 | 730 |  |

| 90 | 45 | 232 | 635 |  |

| 90 | 50 | 210 | 615 |  |

| 90 | 45 | 220 | 622 |  |

| 90 | 45 | 240 | 615 |  |

| 90 | 45 | 165 | 615 |  |

| 100 | 50 | 270 | 676 |  |

Key Features of Steering Hydraulic Cylinder:

- Increased Steering Efficiency: Experience effortless steering! The hydraulic cylinder significantly reduces the effort required to turn the wheel, making driving more enjoyable, especially in larger vehicles or during low-speed maneuvers.

- Enhanced Control: Gain confidence on the road. This component delivers precise steering responses, allowing for improved handling during turns and tight corners, ensuring you stay in control no matter the situation.

- Durable Construction: Built to last! Crafted from robust materials, the steering hydraulic cylinder withstands high pressure and resists wear, providing reliability and longevity for your vehicle’s steering system.

- Compact Design: Space-saving innovation. The cylinder’s sleek design integrates seamlessly into your vehicle’s steering system without occupying unnecessary space, ensuring optimal performance without compromise.

- Versatile Compatibility: Adaptable to your needs. Designed to work with various types of hydraulic fluids, the steering hydraulic cylinder offers versatility across different vehicle models, making it a perfect fit for a wide range of applications.

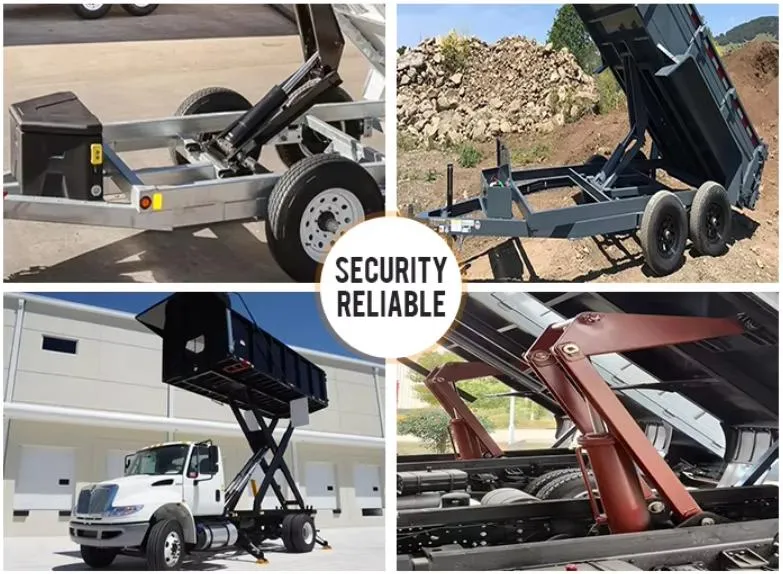

Steering Hydraulic Cylinder Application:

Usage Method for the Steering Hydraulic Cylinder:

Utilizing a steering hydraulic cylinder is a seamless process integral to modern vehicle operation. This component works automatically within the vehicle’s steering system, enhancing your driving experience. Here’s a closer look at how it functions:

1. Power Steering Activation

The power steering pump kicks into action when you turn the steering wheel. It generates hydraulic pressure, providing the necessary force to assist with steering. This activation is almost instantaneous, allowing for quick and responsive handling.

2. Fluid Movement

As the hydraulic pump builds pressure, hydraulic fluid flows through the system and into the steering hydraulic cylinder. This fluid is specially formulated to withstand high pressures and maintain optimal performance. The fluid flow pushes the piston inside the cylinder, creating a powerful force that directly assists your steering efforts.

3. Assistance in Steering

The movement of the piston is where the magic happens. As it extends and retracts, it helps to turn the steering rack with minimal effort. This action translates into smoother steering, especially during tight turns or navigating parking lots. You’ll notice that even larger vehicles become easily handled, allowing for precise control and maneuverability.

What Maintenance Practices Are Recommended For Steering Cylinders?

Here’s a more detailed look at the maintenance practices for steering cylinders:

1. Regular Inspections

- Visual Checks: Conduct a visual inspection of the steering cylinder, hoses, and connections for any signs of wear, cracks, or leaks.

- Physical Inspection: Gently wiggle the cylinder to check for excessive play or looseness, indicating wear in the mounting or other components.

2. Fluid Checks

- Hydraulic Fluid Levels: Regularly check the reservoir to ensure levels are within the recommended range. Low fluid can lead to poor steering performance.

- Fluid Condition: Inspect the fluid for contamination or discoloration. If the fluid appears dirty or has a burnt smell, it may need to be replaced.

3. Cleanliness

- Debris Prevention: Use a clean cloth to wipe down the cylinder and surrounding areas to prevent dirt from entering the system, which can cause wear or damage.

- Seal Protection: Ensure the seals are free from debris that could compromise their integrity.

4. Seal Maintenance

- Seal Inspection: Examine seals for cracks, tears, or signs of wear. Damaged seals should be replaced promptly to prevent leaks.

- Lubrication: Apply appropriate lubricant to seals as the manufacturer recommends to ensure smooth operation and reduce friction.

5. Alignment Checks

- Wheel Alignment: Misalignment can cause uneven wear on components, including the steering cylinder. Have the alignment checked regularly, especially after hitting a pothole or curb.

- Suspension Inspection: Inspect suspension components for wear, as they play a crucial role in maintaining proper alignment and reducing strain on the steering system.

6. Testing Performance

- Steering Feel: Pay attention to how the steering responds while driving. Any stiffness, looseness, or strange noises can indicate an underlying issue.

- Noise Assessment: Listen for grinding, clunking, or whining noises when turning the wheel, which may suggest problems with the steering cylinder or associated components.

Application of Steering Hydraulic Cylinder

Steering hydraulic cylinders are essential components of steering systems in various types of vehicles. These cylinders, also known as steering actuators, help to convert energy generated by a steering pump into linear motion that can be used to manipulate the direction of a vehicle’s wheels. Here are some of the applications of steering hydraulic cylinders:

- Heavy-duty vehicles:Steering hydraulic cylinders are commonly used in heavy-duty vehicles such as trucks, buses, and construction equipment. These vehicles require a lot of force to steer, and a hydraulic cylinder can generate the necessary power to turn the wheels even when the vehicle is loaded with weight. The hydraulic system also allows for finer control over the steering mechanism, making it easier for drivers to navigate large, unwieldy vehicles.

- Off-road vehicles:Off-road vehicles such as ATVs, dune buggies, and dirt bikes also benefit from steering hydraulic cylinders. These vehicles often operate in rough terrain where conventional steering mechanisms may not be effective. Hydraulic cylinders can provide the necessary power and precision to steer through obstacles and maintain control over the vehicle.

- Marine and aerospace applications:Steering hydraulic cylinders are not limited to land-based vehicles. They are also used in marine applications such as boats and ships, as well as in aerospace technology such as spacecraft and airplanes. In these settings, hydraulic cylinders are used to manipulate the direction of rudders, fins, and other control surfaces that help to steer the vessel or aircraft.

- Industrial equipment:Hydraulic cylinders are also used in a variety of industrial settings for steering and other applications. For example, they may be used to steer cranes, forklifts, or other heavy machinery. In these settings, hydraulic cylinders can provide the necessary power and precision to manipulate large loads or operate in tight spaces.

- Custom applications:In addition to these common applications, steering hydraulic cylinders can also be used in a variety of custom settings. For example, they may be used in experimental vehicles or prototypes that require a unique steering mechanism. They may also be used in artistic installations or kinetic sculptures that require precise and controlled movement.

As you can see, steering hydraulic cylinders have a wide range of applications in various industries and settings. Whether they are used in heavy-duty vehicles, off-road vehicles, marine and aerospace applications, industrial equipment, or custom applications, these cylinders provide the necessary power, precision, and control to steer effectively.

About FMP

FMP is a leading manufacturer and distributor of high-quality hydraulic cylinders, cylinder kits, and components for construction machinery. With many years of industry experience and a professional team, we are committed to providing our customers with reliable and efficient solutions to their construction machinery needs.

Here are five reasons why you should choose FMP:

- High-quality hydraulic cylinders: We use precision engineering to manufacture our hydraulic cylinders. Our firm commitment to quality ensures that we use only the highest-quality raw materials and perform strict quality inspections of finished products to ensure they meet and exceed industry standards.

- Extensive product range: Our product range covers all types of construction machinery and accessories. We offer various hydraulic cylinders, gearboxes, chains, sprockets, engine accessories, hydraulic system components, chassis accessories, and electrical system accessories.

- Established partnerships: We have established long-term and stable partnerships with many high-quality domestic and foreign suppliers. This ensures that all supplied accessories meet our strict quality standards.

- Experienced sales team: Our sales team has many years of experience and knowledge of the construction machinery industry. They can provide professional product consultation and smart purchasing advice to help you make informed decisions.

- Efficient logistics distribution system: We have an efficient logistics distribution system to ensure that our customers receive the required parts in a timely and accurate manner.

At FMP, we are committed to providing our customers with high-quality and reliable construction machinery accessories and complete machine solutions. With our modern factory facilities, CNC machine tools, computer-aided design, skilled employees, hydraulic system experts, cylinder assemblers, and dealers, we are the preferred partner to meet your needs for hydraulic cylinders, cylinder kits, and components.

Author: CX