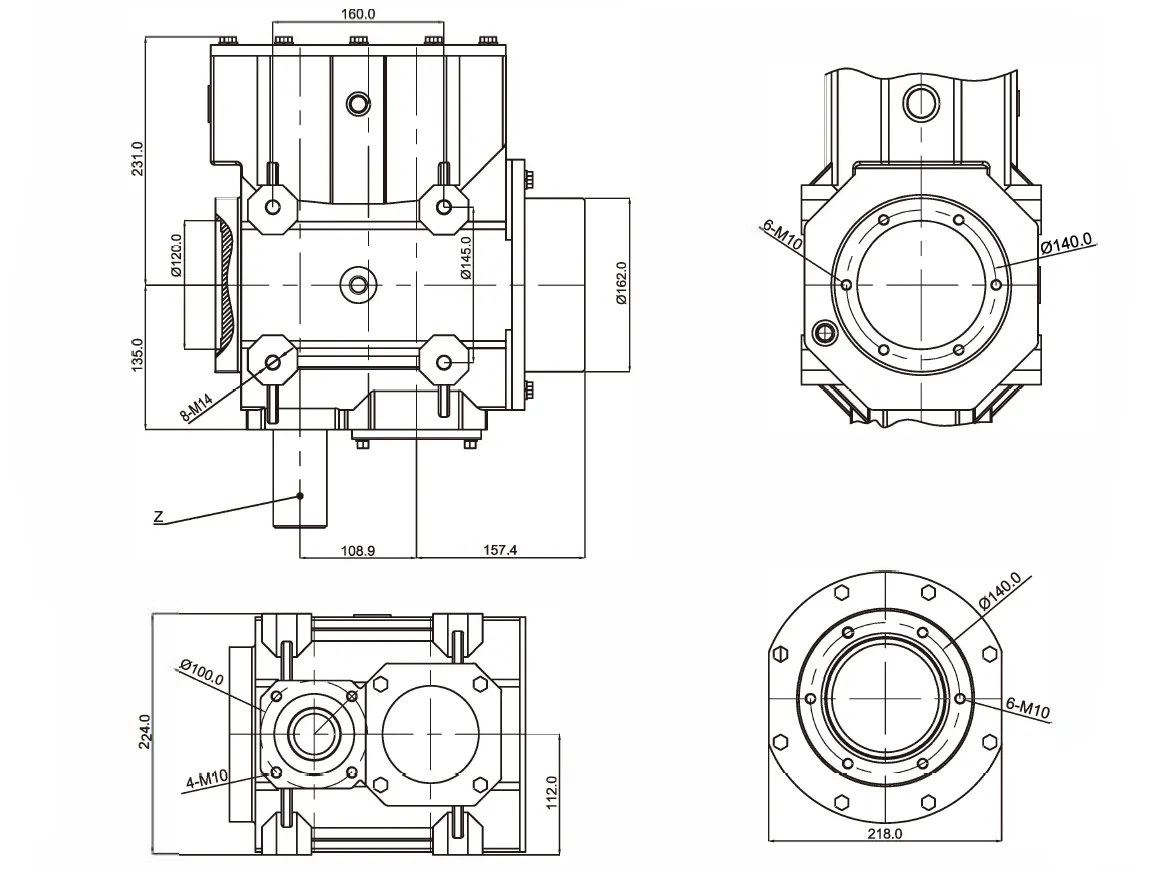

Grader Driven Rake Gearbox FMP112 Dimensions

Grader Driven Rake Gearbox FMP112 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | KW(Max) | Toothing | |

| r/min | r/min | hp | hp | ||||

| Decelerate | 1.62:1 | Rotary Tillers, Beaters, etc | 540 | 333 | 76 | 116 | Gleason Helical Teeth |

| Decelerate | 1.82:1 | 540 | 296 | 70 | 120 | ||

| Decelerate | 2.03:1 | 540 | 266 | 68 | 114 | ||

| Decelerate | 2.28:1 | 540 | 236 | 62 | 105 | ||

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

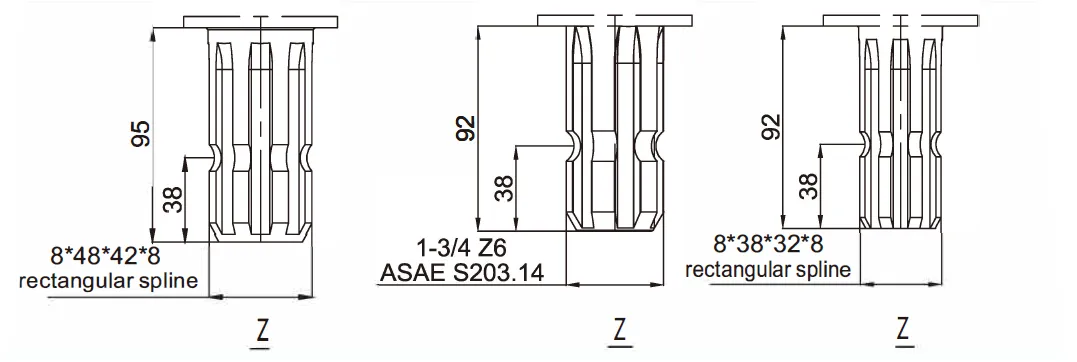

Grader Driven Rake Gearbox FMP112 Shaft Dimensions

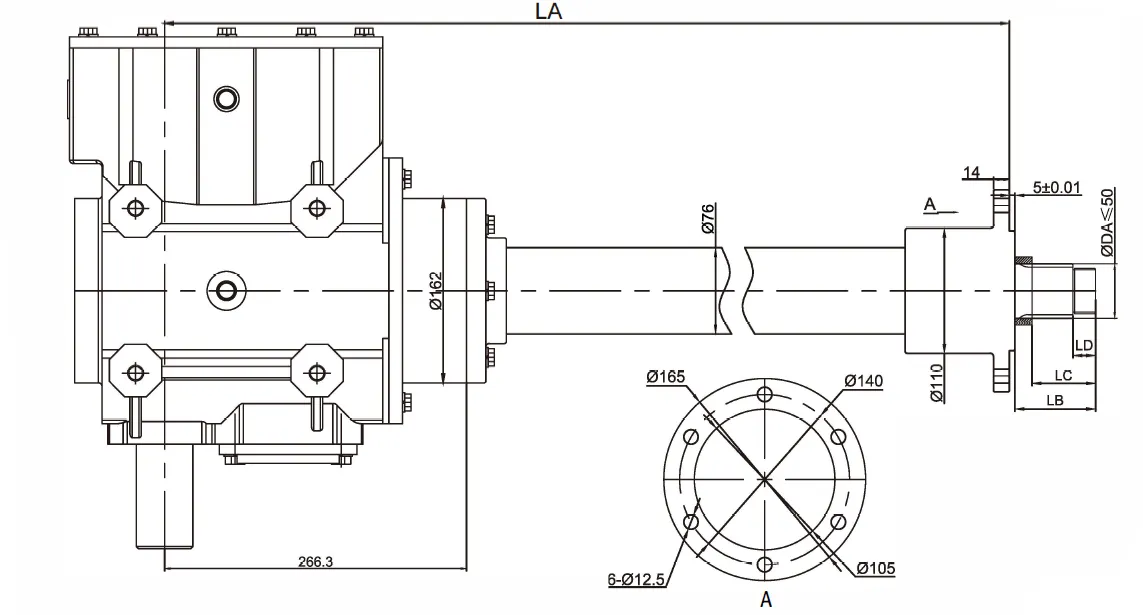

Grader Driven Rake Gearbox FMP112 Extension Pipe

Grader Driven Rake Gearbox FMP112 Components

The Grader Driven Rake Gearbox FMP112 typically consists of the following key components, designed to provide efficient power transmission and reliable operation in agricultural and industrial applications:

- Housing: The outer casing of the gearbox, usually made of high-strength cast iron or steel, provides structural support and houses the internal components. It is designed to withstand heavy loads and protect the internal gears from external elements.

- Input Shaft: This shaft connects to the power source (e.g., a tractor or other equipment) and transmits the input rotational energy into the gearbox. It is typically driven by a PTO shaft or another drive mechanism.

- Output Shaft: The output shaft transfers power from the gearbox to the rake or other driven machinery. It is designed to handle the torque and speed requirements of the application.

- Gears: These are the heart of the gearbox, responsible for transmitting motion and adjusting the rotational speed and torque. Depending on the design, the gearbox may feature bevel gears, helical gears, or worm gears to achieve the desired output characteristics.

- Bearings: Bearings support the rotating components of the gearbox, including the input, output, and intermediate shafts. They reduce friction and ensure smooth rotation while absorbing axial and radial loads.

- Seals and Gaskets: Seals and gaskets are used to prevent leakage of lubricants and contaminants into or out of the gearbox. They are critical for maintaining proper lubrication and ensuring the longevity of the internal components.

- Lubrication System: The gearbox will have a lubrication system, typically using oil or grease, to reduce friction between moving parts and dissipate heat generated during operation. This helps ensure efficient performance and extends the lifespan of the gearbox.

- Shifting Mechanism (if applicable): Some gearboxes feature a shifting mechanism that allows the operator to adjust the speed or torque settings. This mechanism typically consists of levers or selectors that engage different gears.

- Pinion and Gear Sets: The pinion and corresponding gears work together to provide the correct torque and speed ratios, essential for efficient operation in raking applications.

- Housing Cover and Fasteners: The housing cover is used to seal the gearbox and provide access to internal components for maintenance. Fasteners, such as bolts or screws, secure the housing and cover in place.

These components collectively work to ensure that the Grader Driven Rake Gearbox FMP112 provides the required power transmission and durability, effectively supporting tasks in agricultural machinery such as raking, grading, and other heavy-duty applications.

Grader Driven Rake Gearbox FMP112 Applications

The Grader Driven Rake Gearbox FMP112 is designed for use in a variety of agricultural and industrial applications, where efficient power transmission and reliable performance are critical. Some common applications include:

- Agricultural Machinery:

- Rake Systems: The FMP112 gearbox is widely used in agricultural rakes, such as those for hay, straw, or grass raking. It efficiently transmits power from the tractor to the rake, ensuring uniform and effective windrowing and spreading of material.

- Mower Conditioners: In mower conditioners, the gearbox helps drive the conditioning system, improving the drying process for harvested crops like hay or silage.

- Tedders: The gearbox is used in tedding machines, which help in turning hay or grass to facilitate drying. It ensures that the machine operates efficiently at the required speed.

- Grading and Landscaping Equipment:

- Grader Blades: The gearbox can be found in grader blades used for leveling and smoothing soil in construction and landscaping projects. The gearbox transmits power from the vehicle’s PTO to the grader blade, ensuring it works effectively.

- Road Maintenance: In road maintenance equipment, the FMP112 gearbox helps drive the raking and grading functions, assisting in the maintenance and restoration of roads and other infrastructure.

- Forestry Equipment:

- Woodchip Rakers: The gearbox is often used in forestry equipment, particularly in woodchip raking systems where it helps in distributing wood chips evenly across the ground for efficient processing or drying.

- Brush Clearing Machines: It is used in brush clearing machines for effective vegetation management, ensuring smooth operation for clearing operations in forestry and land management.

- Silage and Hay Harvesting:

- Windrowers: In hay and silage harvesting, the gearbox is used in windrowers to drive the raking mechanism, enabling the machinery to windrow and arrange crops efficiently for easy harvesting or baling.

- Irrigation Systems:

-

- Irrigation Equipment: In some irrigation systems, the gearbox helps power rotating rake arms or similar mechanisms that distribute water evenly across fields, ensuring optimal crop growth and efficiency.

-

In these applications, the Grader Driven Rake Gearbox FMP112 ensures that the machinery operates at optimal speeds and torque, providing efficiency, durability, and effective performance across a variety of tasks.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in the design, development, and production of high-performance gearboxes, with a special focus on the agricultural machinery industry. Known for its precision engineering, innovative solutions, and unwavering reliability, FMP has earned a reputation as a trusted partner to both agricultural and industrial sectors. Our extensive product range includes custom-engineered gearboxes for lawn mowers, PTO shafts, and other essential components, all designed to meet the diverse needs of a broad spectrum of applications.

At FMP, we understand that each client has unique challenges and requirements. This is why we specialize in providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our customers, we ensure that every solution not only meets their specific needs but also enhances both performance and value. Our commitment to fast, professional responses, along with expert guidance, guarantees that every inquiry is addressed with the utmost care and precision, delivering optimal results every time.

We prioritize transparent and continuous communication throughout the entire product development cycle. Our dedicated team works directly with clients to fully comprehend their specific needs, offering insightful recommendations to ensure the best possible outcomes. Whether we’re designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to consistently exceed client expectations, providing exceptional service and results on every project.

Quality is the foundation of FMP’s operations. We adhere to the highest manufacturing standards and implement rigorous quality control measures to ensure that each product not only meets but exceeds industry benchmarks. This dedication to excellence, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build lasting, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to cultivate global partnerships and is committed to offering expert advice and customized solutions that meet the evolving needs of our clients. We go beyond merely supplying products—we aim to forge enduring relationships that contribute to the success of each project. Whether you need innovative solutions for a new venture or ongoing support for an existing system, FMP is ready to meet your technical challenges and ensure your ongoing success.

Author: CX