Fertilizer Spreader Gearbox L-25A Specifications

|

|

| Product Description |

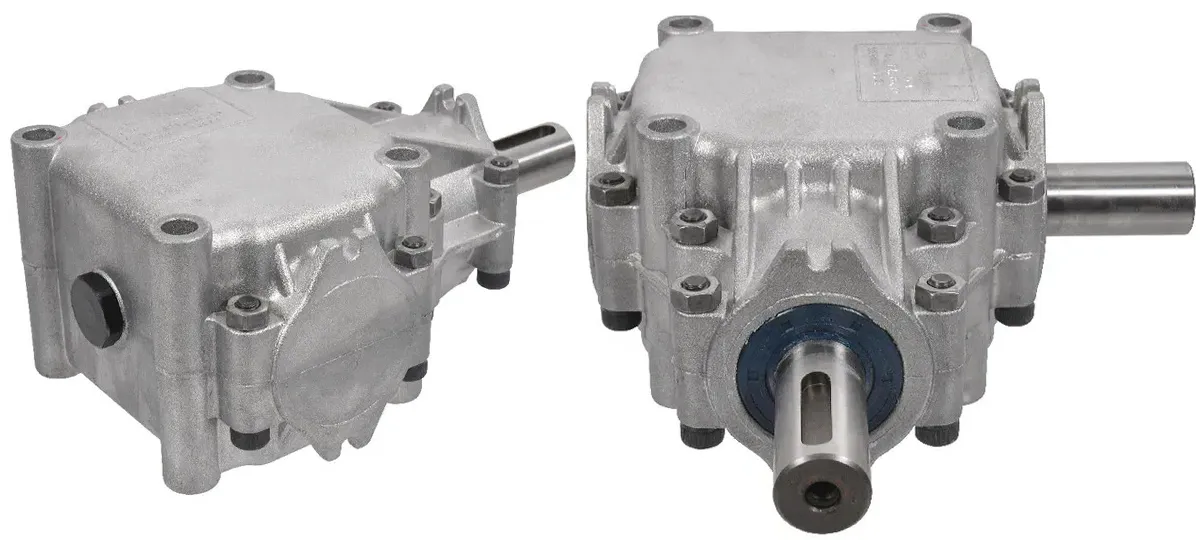

Fertilizer Spreader Gearbox – Replacement of Comer Gearbox L-25A

|

|---|---|

| Product details |

|

| Application range |

|

| Consists of |

|

| Contains oil |

No

|

| Max. oil capacity |

0.35 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Aluminium

|

| Weight |

4.2 kg

|

| Input power kW / HP Increasing |

5 / 6.8 kW/HP

|

| Input power KW / HP Reducing |

2.2 / 3 kW/HP

|

| Output Torque DaNm Increasing |

2.9 daNm

|

| Ratio Increasing |

1 : 3

|

| Ratio Reducing |

3:1

|

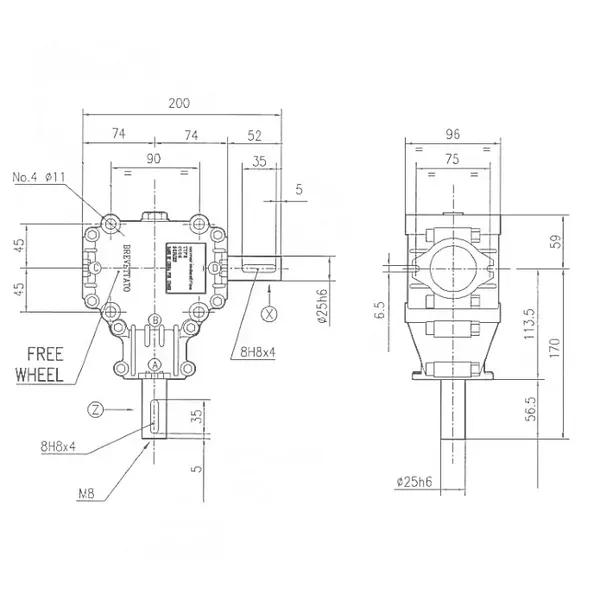

| Input shaft |

X

|

| Shaft X |

25 h6

|

| Shaft Z |

25 h6

|

Benefits of Using a Fertilizer Spreader Gearbox L-25A

- Improved Efficiency in Fertilizer Distribution

The Fertilizer Spreader Gearbox L-25A is designed to optimize the spreading process, ensuring an even and consistent distribution of fertilizer across the field. This results in more accurate application rates, which can lead to better crop yields and reduced waste of fertilizer. The gearbox’s precise control over the spreader’s mechanisms enhances the overall efficiency of the fertilizer application process, saving both time and resources. - Durable and Robust Design

Built with high-quality materials, the L-25A gearbox is engineered to withstand the challenging conditions of agricultural environments. Whether in dusty, wet, or rugged terrain, the gearbox remains reliable, minimizing the risk of breakdowns. Its heavy-duty construction ensures that it can handle the stresses associated with heavy workloads, making it a long-lasting investment for farmers looking to improve their operational efficiency. - Enhanced Power Transmission

The L-25A gearbox is designed to provide reliable power transmission from the tractor’s PTO to the fertilizer spreader, ensuring smooth and efficient operation. With its ability to effectively transfer power, the gearbox reduces energy loss and ensures that the spreader’s working components, such as the agitators and spreader discs, function at optimal speeds. This leads to better coverage and more uniform application, which is critical for ensuring even fertilizer distribution. - Minimal Maintenance Requirements

Thanks to its high-quality construction and advanced design, the L-25A fertilizer spreader gearbox requires minimal maintenance. The gearbox is designed to operate efficiently over long periods without frequent servicing, which reduces downtime and operational costs for farmers. Regular inspections and basic maintenance are all that’s required to keep it in top working condition, making it a cost-effective choice for agricultural operations. - Versatility and Compatibility

The L-25A gearbox is highly versatile and compatible with a wide range of fertilizer spreader models and tractor configurations. This flexibility makes it an ideal choice for farmers with different machinery setups. Whether used in small-scale farming or larger agricultural operations, the L-25A gearbox can easily adapt to various requirements, making it a highly functional and adaptable component for fertilizer spreading systems.

Where Are Fertilizer Spreader Gearboxes Used?

- Agricultural Fields for Crop Fertilization

Fertilizer spreader gearboxes are commonly used in agricultural fields to apply fertilizer evenly and efficiently across large areas. These gearboxes are integral components of fertilizer spreaders, which are used by farmers to ensure that their crops receive the correct amount of nutrients. Whether it’s for crops like wheat, corn, or vegetables, the gearbox helps control the application rate, ensuring optimal growth and yield. - Lawns and Turf Management

In addition to large-scale agriculture, fertilizer spreader gearboxes are also widely used in the landscaping and turf management industry. Golf courses, sports fields, and large lawns rely on efficient fertilizer spreaders to maintain healthy grass and improve soil quality. The gearboxes in these spreaders enable uniform distribution of fertilizers, leading to lush, green turf and reducing the risk of nutrient runoff. - Fertile Land Preparation for Planting

Before planting crops, land preparation is crucial for ensuring soil fertility. Fertilizer spreader gearboxes are used during this phase to apply necessary soil amendments, such as compost or granular fertilizers, that improve the soil’s nutrient profile. By providing a consistent distribution of fertilizer, the gearbox ensures that the land is optimally prepared for planting, resulting in healthier crops and higher productivity. - Orchards and Vineyards

Fertilizer spreader gearboxes are also used in orchards and vineyards where precision fertilization is essential for crop health. The gearboxes control the spreading mechanism to distribute fertilizers evenly around trees or vines, which is especially important for orchards that have specific nutrient requirements for their fruit-bearing plants. The consistent and accurate fertilizer application facilitated by these gearboxes helps improve fruit quality and yield. - Municipal and Commercial Landscaping Projects

Large-scale municipal and commercial landscaping projects, such as parks, recreational areas, and public green spaces, often require the use of fertilizer spreaders equipped with reliable gearboxes. These projects need to maintain soil health and encourage plant growth over large, varied terrains. Fertilizer spreader gearboxes allow for the efficient application of fertilizers and other nutrients, contributing to the aesthetic and environmental benefits of urban and commercial landscapes.

How to Use a Fertilizer Spreader Gearbox?

- Preparation and Setup

Before using a fertilizer spreader gearbox, ensure that the spreader is properly assembled and that all parts are in good working condition. Start by filling the hopper with the desired fertilizer or soil amendment material. Check that the gearbox is securely attached to the spreader and that the PTO shaft is correctly connected to the tractor. Make sure the gearbox settings, such as spread rate and operating speed, are adjusted according to the type of fertilizer being used and the required application rate. - Engage the PTO

Once the spreader is set up, engage the tractor’s PTO (Power Take-Off) system to begin the operation. This will drive the fertilizer spreader gearbox, which in turn powers the spreader’s distribution mechanism. It’s important to ensure that the PTO shaft is properly aligned and securely connected before starting the engine to prevent damage or malfunction. - Adjust the Flow Control

As the PTO is engaged, adjust the flow control lever or valve on the gearbox to regulate the rate at which fertilizer is dispensed. The gearbox allows for precise control over the spreader’s output, ensuring that the right amount of fertilizer is applied over the intended area. Depending on the type of fertilizer and the size of the field, you may need to make fine adjustments to achieve the desired spreading pattern and coverage. - Begin Spreading

With the gearbox running and the flow control adjusted, begin moving the spreader across the field, lawn, or targeted area. The gearbox will continue to regulate the application rate while ensuring an even distribution of fertilizer. Maintain a consistent speed and ensure that the spreader is aligned with the direction of travel to avoid uneven application or overlap. - Monitor and Maintain

During operation, it is crucial to monitor the performance of the fertilizer spreader gearbox. Ensure that the gearbox is not overheating, and check for any irregular sounds or issues with the PTO shaft. Once the fertilizer has been applied, disengage the PTO, turn off the tractor, and perform regular maintenance on the gearbox, including checking the oil level, cleaning the parts, and lubricating the moving components to ensure the gearbox continues to function efficiently for future use.

About FMP

Headquartered in Italy, FMP is a leading manufacturer with a strong reputation for designing, developing, and producing high-performance gearboxes, particularly for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unparalleled reliability, FMP delivers premium products that cater to the ever-evolving needs of both the agricultural and industrial markets. Our extensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other key components, each tailored to provide customized solutions for a wide array of applications.

At FMP, we understand that every client has unique requirements and challenges. This is why we specialize in offering bespoke solutions, whether for individual components or fully integrated systems. We foster close partnerships with our clients to ensure each solution is both highly effective and efficient, maximizing performance and value. Our dedication to fast, professional responses, coupled with expert guidance, ensures that each inquiry is handled with precision and care.

We prioritize clear and continuous communication, particularly when developing new products. Our dedicated team collaborates closely with clients to fully comprehend their needs, providing actionable insights that lead to optimal solutions. Whether we are designing innovative products or fulfilling ongoing orders, we are committed to delivering high-quality, precision-engineered solutions that meet deadlines and exceed expectations.

At the core of FMP’s operations is our steadfast focus on quality. We adhere to the highest manufacturing standards and implement rigorous quality control measures to ensure every product meets or exceeds industry requirements. Our unwavering commitment to quality, along with our core values of integrity, collaboration, and perseverance, has helped us build strong, lasting relationships with customers in over 30 countries worldwide.

FMP is always open to building global partnerships and is dedicated to offering expert advice and tailored solutions to meet the diverse needs of our clients. We believe in building long-term relationships that drive the success of every project. Whether you’re seeking innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to address your technical challenges and ensure your continued success.

Author: CX