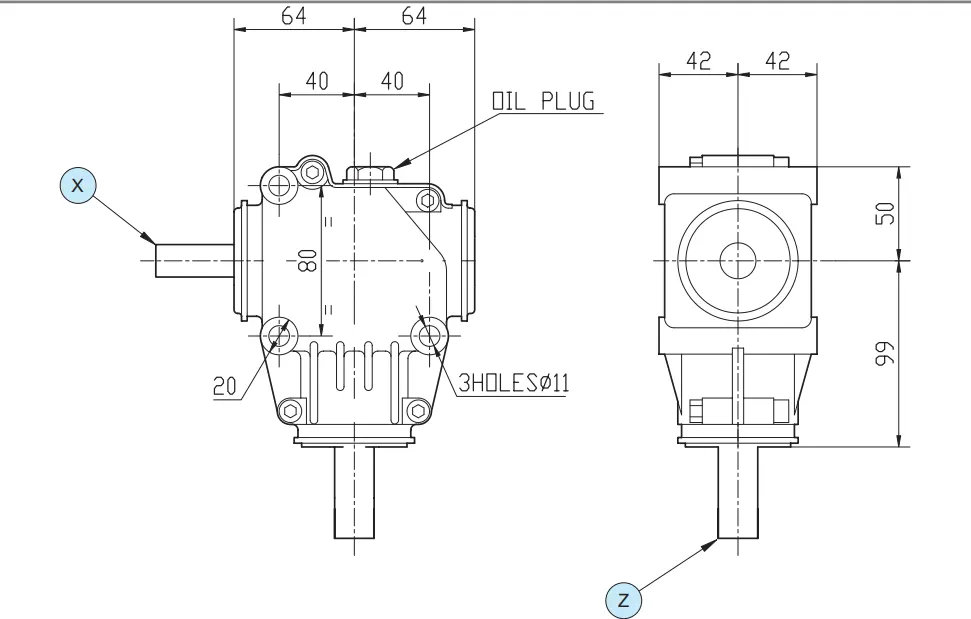

| Technical Features | The FMP-L150J gearbox ratio is 1:1.93. |

|---|---|

| Input Shaft | 1-3/8″ round bore |

| Output Shaft | Tapered splines, bushing must be ordered separately. |

| Gearbox Rating | 60 hp at 540 rpm |

| Rotation | CCW (Counter-clockwise) |

| Compatibility | Fits Replacement of Comer Rotary Cutters |

| Mounting Pattern | 203.2 mm |

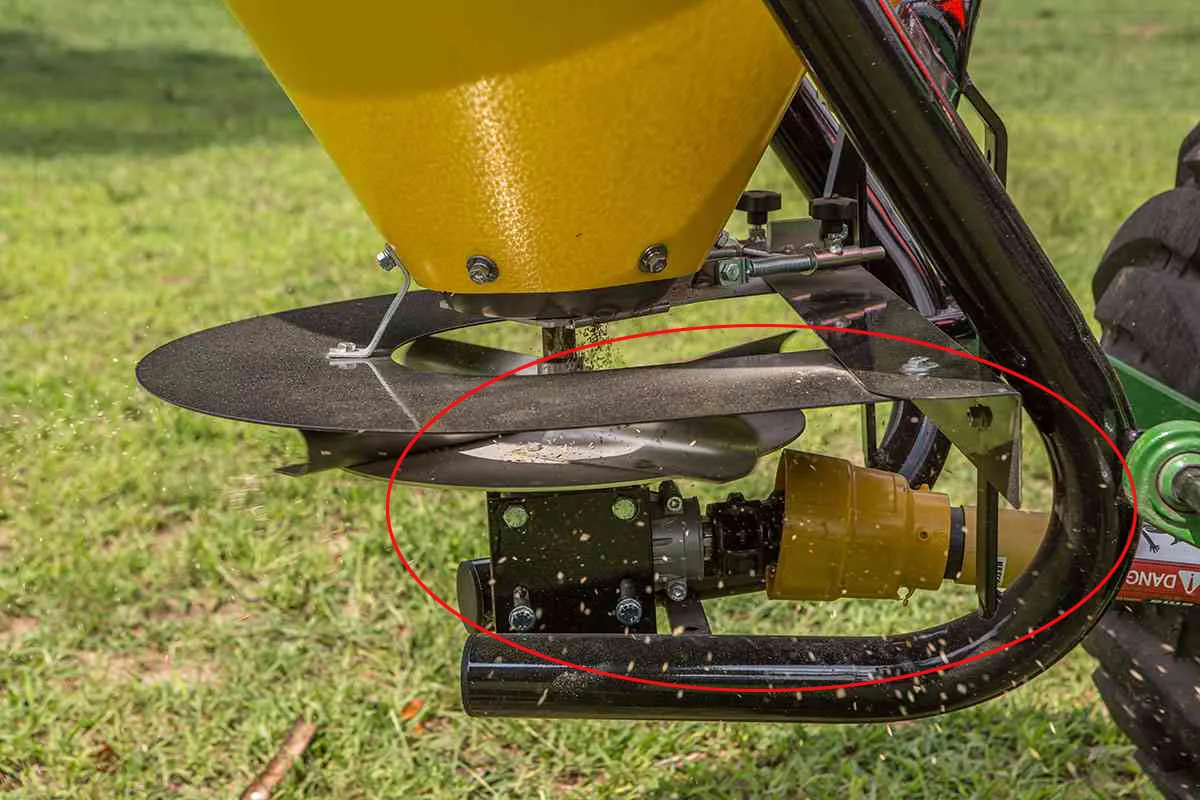

| Application | Fertilizers |

| Body Material | Aluminum |

| Entry Shaft | ΡΤΟ Φ35/Ζ6 (1 3/8″ z6) |

| Exit Shaft | Φ25 mm with two vertical bores. Keyway not available. |

| Entry Power at 540 rpm | 8 kW |

| Lubrication | Grease. Not included. |

| N1[rpm] | P1[kW] | M2[Nm] | Shaft Type | Input | |

| X | Z | ||||

| 540 | 8.0 | 137 | Φ25 | 1” 3/8 Z6 | Z |

| 540 | 8.0 | 137 | Φ25 | Φ25 | Z |

| 540 | 8.0 | 137 | Φ3/4” | Φ3/4” | Z |

PTO Shafts for Fertilizer Spreader Gearbox

PTO shafts for fertilizer spreader gearboxes play a crucial role in transferring power from the tractor to the gearbox, ensuring efficient operation of the spreader. Designed for high-performance applications, these shafts are built to withstand the rigorous demands of spreading fertilizers across agricultural fields. With robust construction and precision engineering, PTO shafts deliver reliable power transmission, contributing to the smooth and consistent operation of the fertilizer spreader.

The design of PTO shafts for fertilizer spreader gearboxes includes features that enhance durability and ease of use. These shafts are equipped with universal joints that allow for flexibility and smooth rotational movement, accommodating varying angles and movement between the tractor and the spreader. The shafts are also designed to handle the torque and stress generated during heavy-duty operation, ensuring long-term reliability even under tough conditions.

FMP’s PTO shafts for fertilizer spreader gearboxes are available in various configurations to suit different models and machinery requirements. Whether you need standard shafts or customized solutions, FMP provides PTO shafts that are compatible with a wide range of agricultural equipment. These shafts are engineered for seamless integration with fertilizer spreader gearboxes, ensuring optimal performance and minimizing downtime during field operations.

Safety and ease of maintenance are also key considerations in the design of these PTO shafts. Each shaft is built with features that make it easy to install, replace, and maintain, reducing the amount of time required for maintenance and repairs. Additionally, the shafts are equipped with safety features, such as shields and guards, to protect operators from potential hazards during operation.

In summary, PTO shafts for fertilizer spreader gearboxes are essential components that ensure the effective transfer of power from the tractor to the fertilizer spreader. FMP’s PTO shafts offer exceptional performance, durability, and ease of use, helping agricultural operators achieve consistent and efficient fertilizer spreading, which is critical for optimal crop growth and farm productivity.

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX