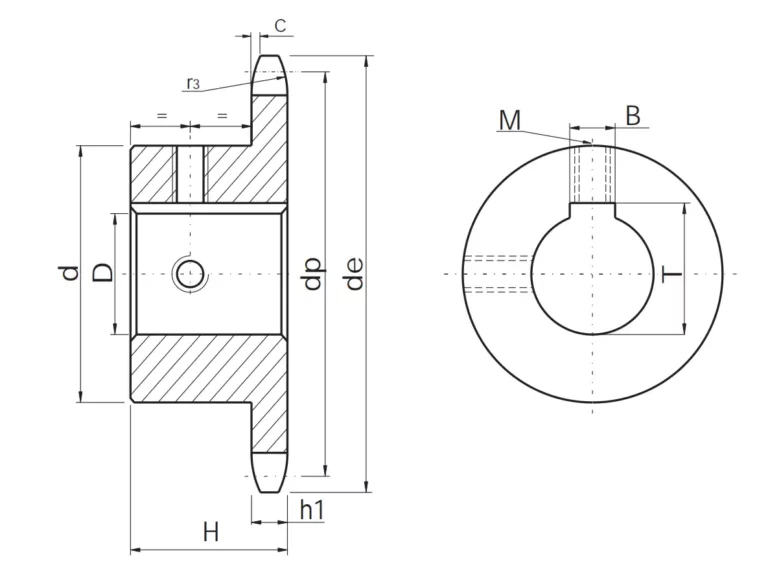

Finished Bore Sprocket

Non-hardened teeth sprocket

These sprockets feature teeth that are not heat-treated or hardened, making them ideal for applications where moderate load capacity and less intense wear are expected. Non-hardened sprockets are typically used in applications with lower-speed operations or environments where wear is not a significant concern.

Hardened Teeth Sprockets

Hardened teeth sprockets are designed with heat-treated teeth for enhanced strength, durability, and wear resistance. The hardened teeth make these sprockets suitable for high-load, high-speed applications or environments where durability and performance are critical. These sprockets are commonly used in more demanding industrial applications, offering longer service life and reliable performance under tough conditions.

Features of Finished Bore Sprocket

- Pre-processed Bore:

The center bore of the sprocket is precisely machined to the required diameter, often including keyways and set screw holes for added convenience during installation. - Shaft Compatibility:

Designed to fit standard shaft sizes, finished bore sprockets minimize the need for additional machining or modifications, ensuring a hassle-free integration into your system. - Keyway:

A keyway is pre-machined into the sprocket to accommodate a key, ensuring reliable torque transfer between the sprocket and shaft, preventing slippage.

- Set Screw Holes:

Pre-drilled set screw holes allow for secure attachment of the sprocket to the shaft, ensuring stable and reliable operation in demanding applications. - Material Options:

Finished bore sprockets are available in a variety of materials, including steel, stainless steel, and plastic, to meet the specific requirements of your application. - Easy Installation:

With pre-machined holes, finished bore sprockets simplify the installation process, eliminating the need for custom bore processing and reducing installation time.

For applications that require quick and direct mounting to a shaft, finished bore sprockets offer a convenient and efficient solution with no additional machining required.