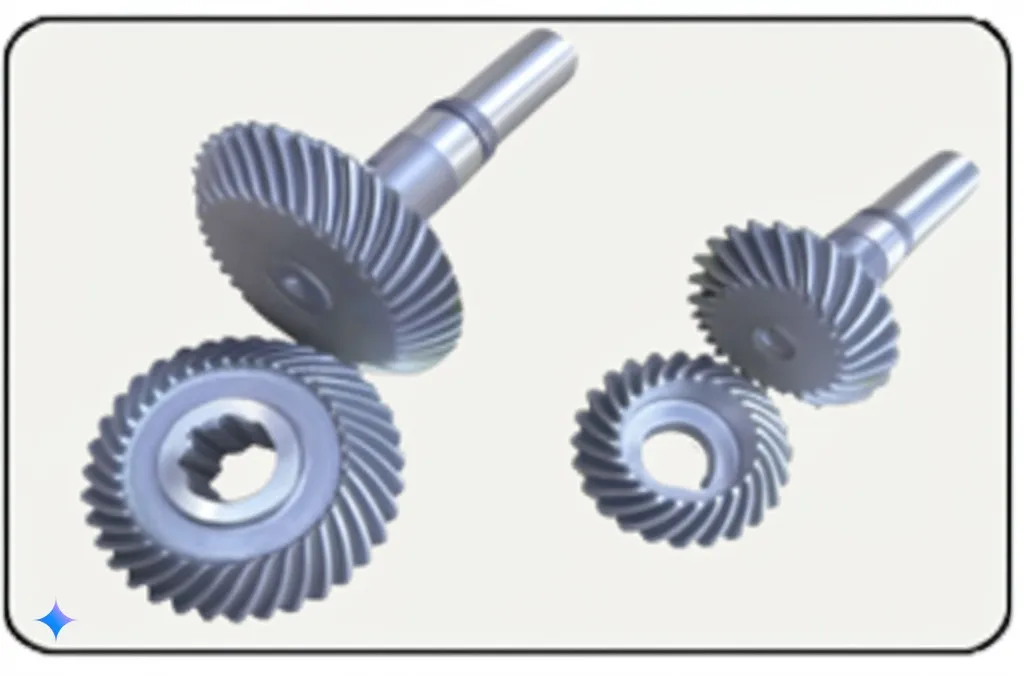

Spiral Bevel Gears (Helical Bevel Gears) are advanced, high-performance gears featuring curved, helical teeth that ensure smoother and quieter operation while efficiently transmitting power between intersecting shafts, making them ideal for demanding applications like automotive, aerospace, and industrial machinery. At FMP Company, we specialize in producing a diverse range of Spiral Bevel Gears (Helical Bevel Gears), crafted to meet various specifications, and we also offer custom manufacturing to suit your unique requirements. If the specific model you need isn’t listed in our product catalog, don’t worry—it’s likely just awaiting upload; simply email us with your desired specifications, and our expert engineers will get back to you within 24 hours with tailored solutions.

Spiral Bevel gears gearbox Spiral Bevel gears gearbox |

|

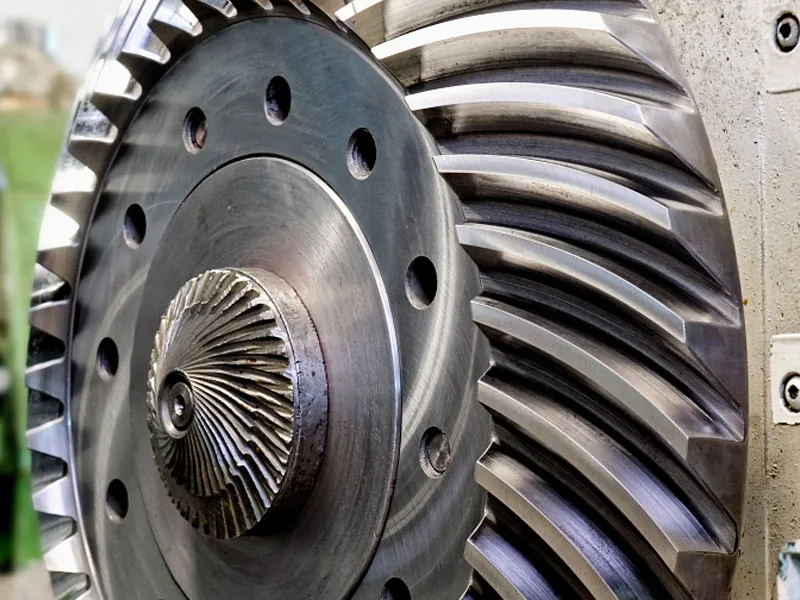

Spiral bevel gears machinery Spiral bevel gears machinery |

Spiral bevel gears Speed reducers Spiral bevel gears Speed reducers |

Spiral Bevel Gears VS Hypoid Gear

| Spiral Bevel Gears | Hypoid Gear |

|

|

Spiral Bevel Gear Application

Bevel gears find applications across diverse industries, from aerospace (high-speed straight and spiral bevel gears, specialized steels, air pre-heaters, etc.) to mining operations (stacker and scoop actuators, wheeled excavators, dredges, conveyor systems, mill actuators, etc.).

They are commonly found in sand mixers, conical mills, cooling towers, forklifts, ship actuators and propellers, pharmaceutical packaging equipment, high-speed offset printing machines, polyethylene sheet manufacturing, automotive components, and railway transmissions.

In robotics, angled bevel gears are ideal for compact spaces, while in ferrous metallurgy, they support vertical rolling mill structures.

In food processing, bevel gears are vital for food production, packaging, and can-making tools.

For low-speed, low-load scenarios, bevel gears efficiently transfer power and motion between two shafts.

Hypoid bevel gears are employed in automotive systems, such as vehicle differential drives.

Bevel gears are also critical in the mechanism of hand drills.

In sewing machines, spiral bevel gears are a key component.

|

|

|

|

|

|

|

|

|

Packaging & Food Processing

|

Railways

|

Printing

|

Mining:

|

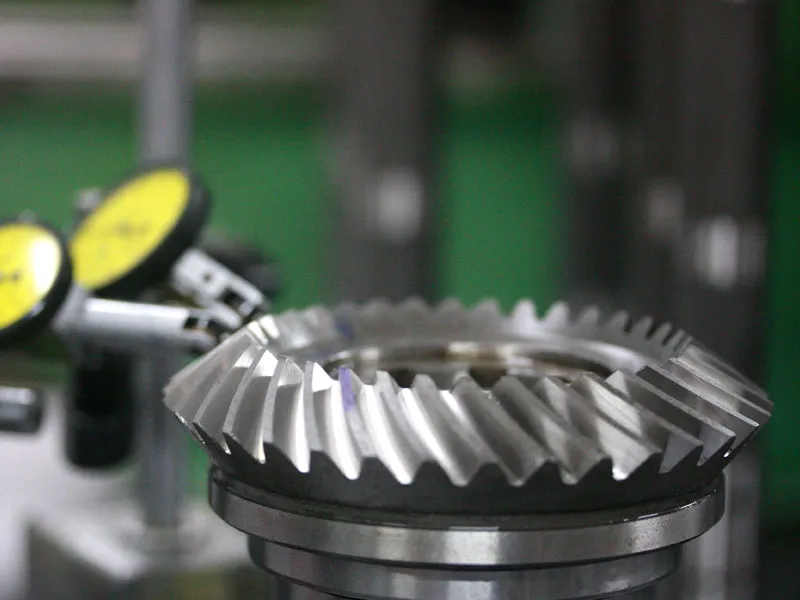

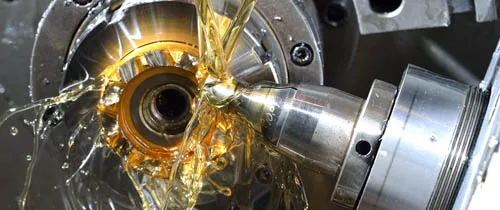

The Manufacturing Process of Spiral Bevel Gears

The manufacturing of bevel gears begins with pre-forming a blank, either with or without teeth, followed by annealing if the material is cast or forged steel, to soften it for further processing. The blank is then machined to precise dimensions, shaping the teeth or refining pre-formed ones as needed.

Next, the gear’s teeth may undergo surface or full hardening to boost durability, depending on its intended use. After hardening, the teeth are finished using grinding or shaving to ensure smoothness and accuracy.

Lastly, the finished bevel gear is carefully inspected to confirm it meets all design and performance standards, ensuring its quality and reliability for practical applications.

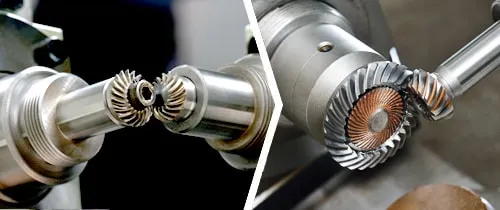

| Spiral Bevel Gear Cutting | Spiral Bevel Gear Grinding |

|

|

| Spiral Bevel Gear Milling | Spiral Bevel Gear Testing |

|

|

Spiral Bevel Gears trucks

Spiral Bevel Gears trucks