|

|

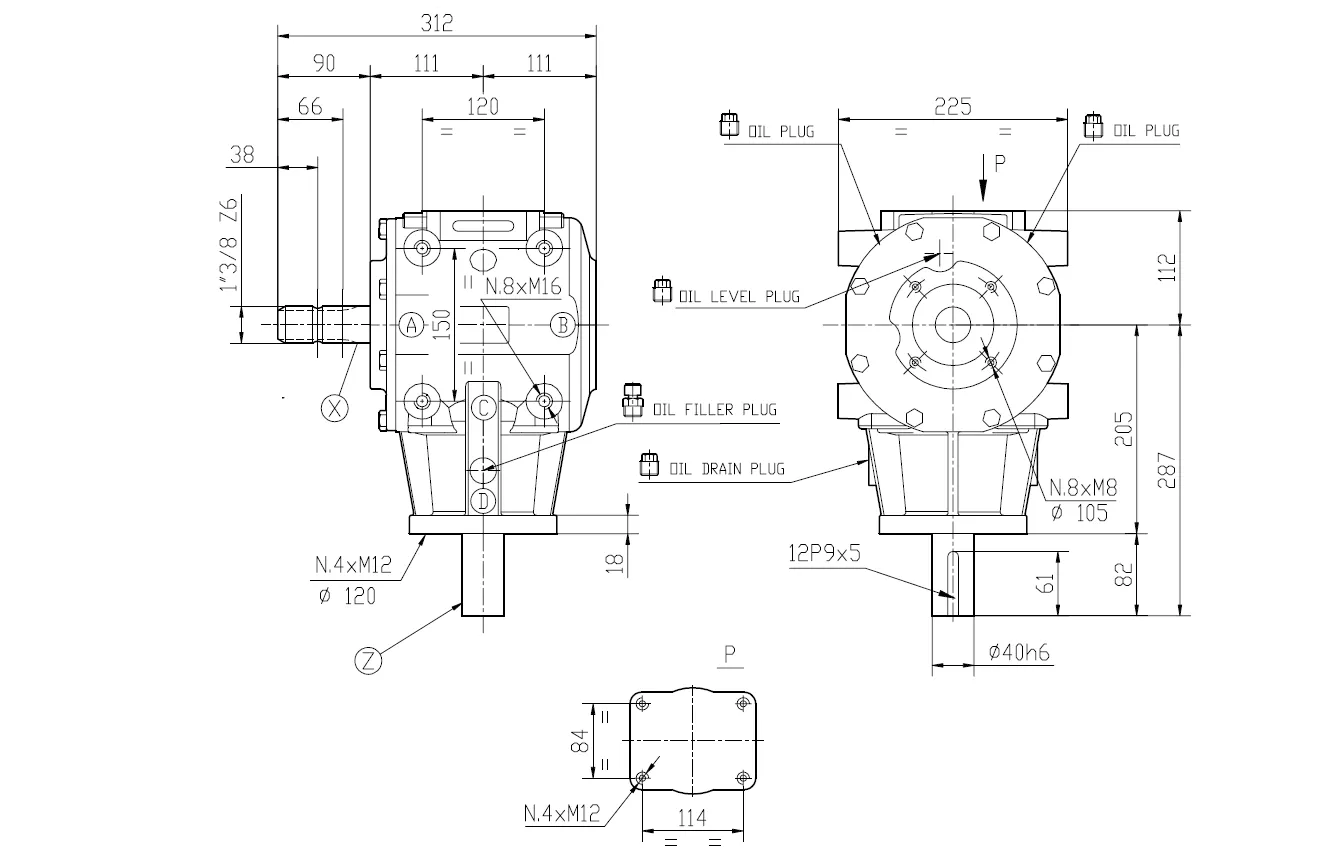

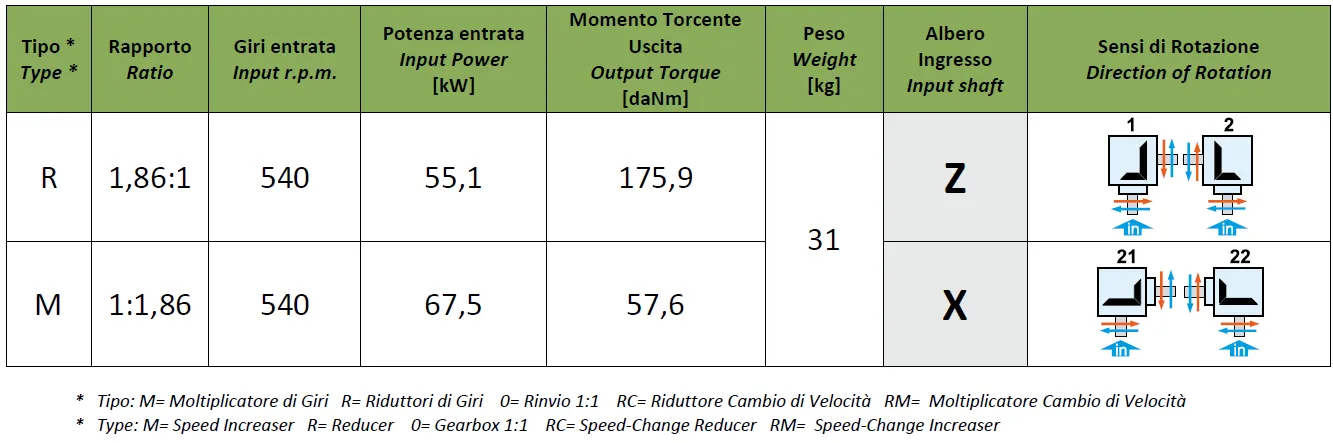

Specifications of Flail Mower Gearbox T-290A (1:1.86)

| وصف |

Flail Mower Gearboxes – Replacement of Comer Gearbox T-290A 1:1.86

|

|---|---|

| طلب |

|

| Consists of |

|

| Technical information |

|

| Max. output torque |

175.9 daNm

|

| Contains oil |

No

|

| Max. oil capacity |

2.3 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| وزن |

30 kg

|

| Gear arrangement Increasing |

25 – 26

|

| Gear arrangement Reducing |

5 – 6

|

| Input power kW / HP Increasing |

62.5 / 85 kW/HP

|

| Input shaft Increasing |

X

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

55.1 / 75 kW/HP

|

| Output Torque DaNm Increasing |

57.6 daNm

|

| Ratio Increasing |

1:1.86

|

| Ratio Reducing |

1.86:1

|

| Shaft X |

1 3/8″ (6) (A)

|

| Shaft Y |

1 3/8″ (6) (A)

|

| Shaft Z |

1 3/8″ (6) (B)

|

Benefits of Flail Mower Gearbox T-290A (1:1.86)

The Flail Mower Gearbox T-290A (1:1.86) is designed for optimal performance, durability, and efficiency in agricultural and landscaping applications. Below are the key benefits of using the T-290A gearbox with a 1:1.86 gear ratio:

Balanced Gear Ratio for Versatile Performance

The 1:1.86 gear ratio of the T-290A gearbox strikes an ideal balance between speed and torque. This ratio provides sufficient torque for cutting thicker vegetation, such as tall grass and light brush, while maintaining a fast enough blade rotation for efficient cutting. This makes it versatile enough for a range of applications, from regular lawn maintenance to tougher mowing tasks in more rugged terrain.

Improved Power Transmission Efficiency

The T-290A gearbox is designed to minimize power loss during the transfer from the PTO shaft to the mower blades. The high-quality gearing system ensures efficient energy transfer, making the mower more energy-efficient and reducing fuel consumption in the long run. This helps maximize the power output from the tractor and improves the overall performance of the flail mower.

Durable and Heavy-Duty Construction

Constructed from high-strength steel and premium materials, the T-290A gearbox is built to withstand harsh agricultural environments and tough field conditions. Its reinforced gears and robust bearings ensure that the gearbox operates reliably, even under heavy workloads. Whether you are working in dry, rocky terrain or wet, muddy fields, this gearbox can handle the stress, offering a long lifespan and consistent performance.

Reduced Maintenance and Longevity

With proper maintenance, the T-290A gearbox offers low maintenance requirements. The durable construction and sealed bearings reduce the likelihood of dirt and moisture entering the system, minimizing wear and tear. Regular lubrication and inspection are all that’s needed to keep the gearbox running smoothly. This results in fewer breakdowns, reduced repair costs, and a longer service life for both the gearbox and your mower.

Enhanced Cutting Efficiency

The gearbox is engineered to deliver steady and reliable torque to the mower blades, ensuring an even and consistent cut. The 1:1.86 gear ratio allows for optimal blade speed, resulting in clean, precise cutting of grass, weeds, and small brush. Whether you are maintaining pastures, roadsides, or commercial landscapes, the T-290A gearbox enhances the mower’s ability to handle a variety of cutting tasks with ease.

The Flail Mower Gearbox T-290A (1:1.86) offers a combination of efficiency, durability, and versatility. Its balanced gear ratio optimizes performance for a range of cutting tasks, while the robust construction ensures long-lasting reliability in demanding environments. With low maintenance requirements, enhanced cutting efficiency, and built-in safety features, the T-290A gearbox is an excellent choice for anyone looking to maximize the performance of their flail mower.

|

|

How Does the Flail Mower Gearbox Work?

The flail mower gearbox is a critical component in converting power from the tractor’s PTO (Power Take-Off) system to the mower blades. It controls the rotational speed and torque applied to the flail blades, enabling them to cut grass, weeds, and brush efficiently. Here’s a step-by-step explanation of how it works:

Power Transfer from the Tractor’s PTO Shaft

The PTO shaft from the tractor connects to the input side of the flail mower gearbox. The PTO system is driven by the tractor’s engine and provides mechanical power to various implements, including the flail mower. The rotating PTO shaft transmits power through a series of gears inside the gearbox. This power is essential for driving the mower blades.

Gearbox Transmits Power and Adjusts Torque

Inside the gearbox, a series of gears, shafts, and bearings work together to adjust the speed and torque of the power being received from the PTO shaft. The gear ratio within the gearbox determines the output speed and the amount of torque applied to the mower blades.

- High gear ratios (e.g., 1:2.91) increase torque, providing more power for tougher cutting conditions, such as thicker vegetation or rough terrain.

- Lower gear ratios (e.g., 1:1.6) increase blade speed, ideal for lighter grass mowing where a faster blade rotation is required for an even cut.

The gearbox effectively adapts the PTO’s high speed and moderate torque to a slower, higher-torque output suitable for mowing.

Power Transfer to the Output Shaft

After the power is adjusted inside the gearbox, it is transferred to the output shaft, which is connected to the mower blades. The output shaft is often connected to a set of pulleys or direct drive links that transfer the rotational power directly to the flail mower blades.

This mechanism allows the flail blades to rotate at the correct speed and torque to efficiently cut through the vegetation. In flail mowers, the blades are mounted on a drum or shaft, which rotates and impacts the grass or brush in a chopping action.

Blade Rotation and Cutting Action

Once the power reaches the flail blades, the blades rotate at high speed. Flail blades are typically arranged on a drum or shaft in a way that allows them to rotate vertically or horizontally to chop vegetation. As the blades spin, they strike the vegetation with force, cutting or shredding it into smaller pieces. The power and rotational speed provided by the gearbox ensure that the blades maintain a consistent cutting performance across various vegetation types.

- Speed and torque are balanced by the gearbox to ensure the blades don’t spin too quickly (which could lead to ineffective cutting) or too slowly (which could cause the mower to bog down or struggle in thicker material).

The gearbox’s role is critical in maintaining the correct balance of power for optimal mowing efficiency.

Continuous Operation with Minimal Interruption

The flail mower gearbox is designed to operate continuously while the tractor is in motion. Because the gearbox is enclosed and typically filled with oil for lubrication, it runs smoothly with minimal maintenance needs during regular operation. The use of sealed bearings and high-quality gears ensures that the gearbox remains reliable even under heavy or prolonged use, providing efficient operation throughout the mowing process.

In summary, the flail mower gearbox plays a crucial role in transmitting and adjusting the power from the tractor’s PTO system to the mower blades. By converting high-speed, low-torque input power into slower, higher-torque output, the gearbox ensures that the flail blades operate efficiently to cut grass, weeds, and brush. The gearbox’s ability to adjust speed and torque according to the specific requirements of the cutting task helps maximize both performance and durability, making it a vital component of the flail mower system.

حول FMP

FMP، التي يقع مقرها الرئيسي في إيطاليا، شركة رائدة في مجال التصنيع، تشتهر بخبرتها في تصميم وتطوير وإنتاج علب التروس عالية الأداء، مع تركيز خاص على قطاع الآلات الزراعية. بفضل سمعتها المتميزة في الهندسة الدقيقة والحلول المبتكرة والموثوقية العالية، أصبحت FMP شريكًا موثوقًا به في تلبية الاحتياجات المتغيرة للقطاعين الزراعي والصناعي. تشمل مجموعتنا المتنوعة من المنتجات علب تروس متخصصة لجزازات العشب، وأعمدة نقل الحركة، ومكونات أساسية أخرى، جميعها مصممة بدقة متناهية لتوفير حلول مخصصة لمجموعة واسعة من التطبيقات.

في FMP، ندرك أن لكل عميل متطلباته وتحدياته الخاصة. ولذلك، نتخصص في تقديم حلول مصممة خصيصًا، سواءً للمكونات الفردية أو الأنظمة المتكاملة. ونتعاون بشكل وثيق مع عملائنا لضمان فعالية كل حل، ليس فقط بل وكفاءته أيضًا، مما يُحسّن الأداء والقيمة. ويضمن التزامنا بتقديم ردود سريعة واحترافية، إلى جانب توجيهات الخبراء، التعامل مع كل استفسار بأقصى درجات العناية والدقة، مما يؤدي إلى أفضل النتائج الممكنة.

نولي أهمية كبيرة للتواصل المفتوح والمستمر طوال عملية تطوير المنتج. يعمل فريقنا المتخصص مباشرةً مع عملائنا لفهم احتياجاتهم الخاصة بشكل كامل، مقدمًا لهم رؤى وتوصيات قيّمة لضمان حلول مثالية. سواءً عند تصميم منتجات مبتكرة أو تلبية طلبات مستمرة، تلتزم FMP بتقديم حلول عالية الجودة ومصممة بدقة وفي الوقت المحدد وفي كل مرة. هدفنا هو تزويد عملائنا بأفضل خدمة ونتائج، متجاوزين توقعاتهم في كل مشروع.

الجودة هي حجر الأساس في عمليات FMP. نلتزم بأعلى معايير التصنيع، ونطبق إجراءات صارمة لمراقبة الجودة لضمان أن كل منتج لا يفي بمعايير الصناعة فحسب، بل يتجاوزها. هذا الالتزام الراسخ بالجودة، إلى جانب قيمنا الأساسية المتمثلة في النزاهة والعمل الجماعي والمثابرة، مكّننا من بناء علاقات طويلة الأمد قائمة على الثقة مع عملائنا في حوالي 30 دولة حول العالم.

تحرص FMP دائمًا على تعزيز الشراكات العالمية، وتلتزم بتقديم استشارات متخصصة وحلول مُخصصة تُلبي احتياجات عملائنا المتنوعة. لا يقتصر عملنا على توريد المنتجات فحسب، بل نهدف إلى بناء علاقات متينة تُسهم في نجاح كل مشروع. سواءً كنتم بحاجة إلى حلول مبتكرة لمبادرة جديدة أو دعم مستمر لنظام قائم، فإن FMP هنا لمساعدتكم في مواجهة تحدياتكم التقنية وضمان استمرار نجاحكم.

المؤلف: CX