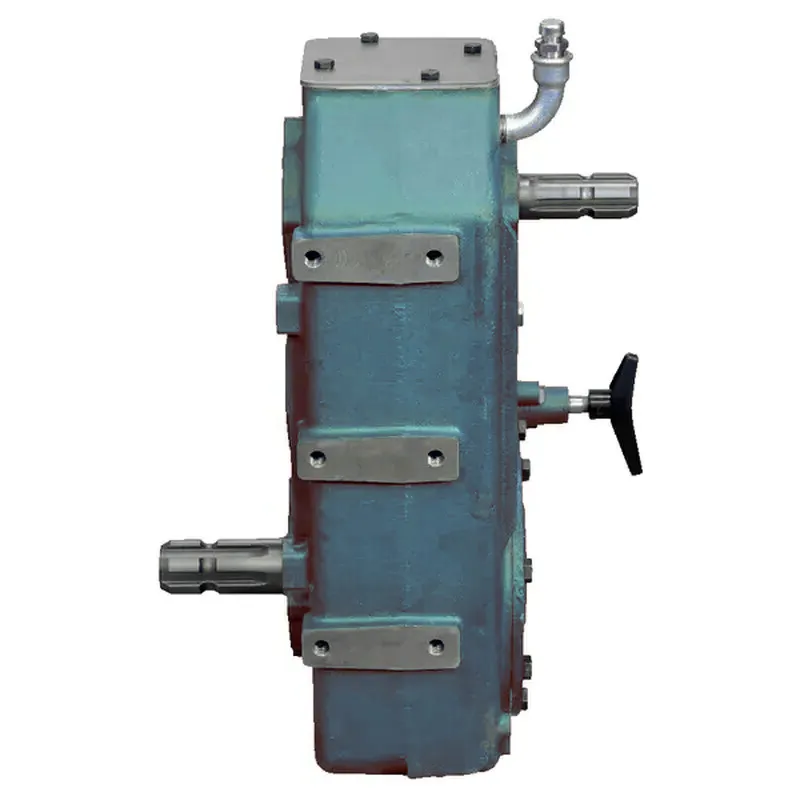

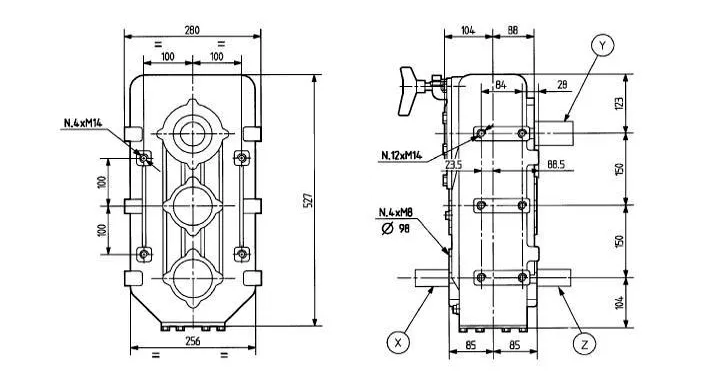

Horizontal Feed Mixer Gearbox D732A Dimensions

Product Specifications:

| Product Description |

Horizontal Feed Mixer Gearbox-Replacement of Comer D732A Gearbox

|

|---|---|

| Product details |

|

| Application range |

Mixing wagon

|

| Consists of |

|

| Max. input power |

59 kW

|

| Max. output power |

80 HP

|

| Connection 1 outside diameter |

1-3/8 Inch

|

| Connection 1 number of splines |

6

|

| Connection 2 outside diameter |

1-3/4 Inch

|

| Connection 2 number of splines |

6

|

| Contains oil |

No

|

| Max. oil capacity |

5,6 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| وزن |

63 kg

|

Advantages of Using the Horizontal Feed Mixer Gearbox D732A

- Enhanced Mixing Efficiency

The Horizontal Feed Mixer Gearbox D732A is specifically designed to provide excellent mixing performance. With its high torque and efficient power transmission, it ensures a consistent and uniform blend of feed ingredients. This leads to more effective mixing, improving the overall quality and nutritional value of the feed. - Durable and Reliable Construction

The gearbox is built with high-strength materials that can withstand the tough working conditions of feed mixing. Its rugged design ensures long-term durability, even in heavy-duty operations, reducing the need for frequent maintenance or part replacements, and increasing the overall lifespan of the equipment. - Energy Efficiency

The D732A gearbox is designed to optimize power consumption, ensuring efficient use of energy while maintaining high output. This energy-efficient design helps reduce operating costs, making it a cost-effective choice for businesses that rely on continuous feed mixing operations. - Smooth Operation and Low Vibration

Thanks to its advanced engineering, the D732A gearbox ensures smooth operation with minimal vibration, providing stable performance. This not only enhances the reliability of the mixer but also contributes to the comfort and safety of operators, reducing the risk of mechanical failures and improving operational efficiency. - Versatility in Applications

The D732A gearbox is suitable for a wide range of feed mixing applications. Whether it’s for agricultural, livestock, or industrial feed production, this gearbox offers the flexibility to meet diverse operational needs. Its adaptability to different mixing systems makes it an ideal choice for various feed manufacturing processes.

These advantages make the Horizontal Feed Mixer Gearbox D732A a valuable asset for businesses in the agricultural sector, ensuring optimal performance, durability, and efficiency in feed production.

Key Components of Tractor PTO Driven Horizontal Feed Mixer Gearbox

- PTO Shaft Input

The PTO (Power Take-Off) shaft input is the key connection point between the tractor and the feed mixer gearbox. It transfers mechanical power from the tractor’s engine to the gearbox, enabling the mixing operation. The PTO shaft ensures smooth energy transmission, allowing the gearbox to operate efficiently. - Helical Gears

The horizontal feed mixer gearbox typically incorporates helical gears, which provide a smoother and quieter operation compared to other types of gears. These gears are designed to handle high torque loads and ensure efficient power transmission, reducing wear and tear during continuous operation. - Housing

ال gearbox housing is the outer casing that contains all the internal components, such as gears, shafts, and bearings. It is usually made from durable materials like cast iron or high-strength steel, ensuring the gearbox is robust and able to withstand the tough conditions in agricultural settings. - Bearings

Bearings are critical components that support the rotating shafts and reduce friction within the gearbox. They ensure smooth operation and minimize wear, enabling the gearbox to function reliably over long periods without excessive maintenance. - Output Shaft

ال output shaft is connected to the mixing auger or other components of the feed mixer. It transmits the power from the gearbox to the mixing mechanism, enabling the feed ingredients to be blended efficiently. The output shaft must be designed to handle the torque and rotational speed required for optimal mixing performance.

These key components work together to ensure the tractor PTO driven horizontal feed mixer gearbox operates smoothly, efficiently, and reliably, providing optimal performance in agricultural mixing applications.

Working Principle of Feed Mixer Machines Gearboxes

Feed mixer machines are critical for blending different types of animal feed to ensure uniform consistency and nutritional value. The gearbox plays a key role in powering the feed mixing mechanism. Below is the working principle of feed mixer machine gearboxes:

1. Power Transmission from Tractor or Motor to Gearbox

- The gearbox is powered either by a tractor’s PTO shaft or an electric motor, depending on the design of the feed mixer.

- For PTO-driven mixers, the PTO shaft connected to the tractor transfers rotational power from the tractor’s engine to the gearbox.

- For electric motor-driven systems, the motor drives the gearbox directly through a coupling.

2. Speed Reduction and Torque Amplification

- The gearbox serves to reduce the speed of the incoming rotational power while simultaneously increasing the torque. This is essential for driving the heavy mixing blades or augers inside the feed mixer.

- The gear mechanism, typically composed of helical gears, bevel gears, or planetary gears, reduces the rotational speed from the power source and delivers the optimal output speed required for mixing.

3. Rotation of the Augers or Mixing Blades

- The output shaft of the gearbox connects to the mixing auger or blades, which are the core components responsible for moving and blending the feed ingredients.

- As the gearbox delivers power to the auger or blades, the mixing mechanism begins to rotate, lifting and tumbling the feed materials to ensure even distribution and thorough mixing.

- The rotational movement of the augers or blades creates a shearing effect that breaks up clumps of feed ingredients, ensuring a uniform blend.

4. Efficient Material Handling

- The gearbox ensures that the rotational speed of the augers or blades is consistent and manageable, allowing for efficient material handling.

- The design of the gearbox enables the feed materials to be mixed thoroughly without excessive strain or overloading of the motor or PTO shaft.

5. Continuous Power Flow

- A feed mixer gearbox ensures continuous power flow from the input (PTO shaft or motor) to the output (mixing mechanism) during operation.

- Depending on the design, the gearbox may include features such as overload protection, ensuring that any excessive strain or blockage in the system doesn’t damage the gearbox.

In summary, the working principle of feed mixer machine gearboxes involves power transmission from the tractor or motor to the gearbox, which reduces the speed and amplifies the torque to drive the mixing augers or blades. The gearbox ensures efficient and consistent mixing by powering the blades or augers, ensuring that feed ingredients are uniformly mixed to the desired consistency. Proper lubrication and cooling mechanisms also contribute to the smooth operation of the gearbox throughout the process.

حول FMP

FMP، التي يقع مقرها الرئيسي في إيطاليا، شركة رائدة في مجال التصنيع، تشتهر بخبرتها في تصميم وتطوير وإنتاج علب التروس عالية الأداء، مع تركيز خاص على قطاع الآلات الزراعية. بفضل سمعتها المتميزة في الهندسة الدقيقة والحلول المبتكرة والموثوقية العالية، أصبحت FMP شريكًا موثوقًا به في تلبية الاحتياجات المتغيرة للقطاعين الزراعي والصناعي. تشمل مجموعتنا المتنوعة من المنتجات علب تروس متخصصة لجزازات العشب، وأعمدة نقل الحركة، ومكونات أساسية أخرى، جميعها مصممة بدقة متناهية لتوفير حلول مخصصة لمجموعة واسعة من التطبيقات.

في FMP، ندرك أن لكل عميل متطلباته وتحدياته الخاصة. ولذلك، نتخصص في تقديم حلول مصممة خصيصًا، سواءً للمكونات الفردية أو الأنظمة المتكاملة. ونتعاون بشكل وثيق مع عملائنا لضمان فعالية كل حل، ليس فقط بل وكفاءته أيضًا، مما يُحسّن الأداء والقيمة. ويضمن التزامنا بتقديم ردود سريعة واحترافية، إلى جانب توجيهات الخبراء، التعامل مع كل استفسار بأقصى درجات العناية والدقة، مما يؤدي إلى أفضل النتائج الممكنة.

نولي أهمية كبيرة للتواصل المفتوح والمستمر طوال عملية تطوير المنتج. يعمل فريقنا المتخصص مباشرةً مع عملائنا لفهم احتياجاتهم الخاصة بشكل كامل، مقدمًا لهم رؤى وتوصيات قيّمة لضمان حلول مثالية. سواءً عند تصميم منتجات مبتكرة أو تلبية طلبات مستمرة، تلتزم FMP بتقديم حلول عالية الجودة ومصممة بدقة وفي الوقت المحدد وفي كل مرة. هدفنا هو تزويد عملائنا بأفضل خدمة ونتائج، متجاوزين توقعاتهم في كل مشروع.

الجودة هي حجر الأساس في عمليات FMP. نلتزم بأعلى معايير التصنيع، ونطبق إجراءات صارمة لمراقبة الجودة لضمان أن كل منتج لا يفي بمعايير الصناعة فحسب، بل يتجاوزها. هذا الالتزام الراسخ بالجودة، إلى جانب قيمنا الأساسية المتمثلة في النزاهة والعمل الجماعي والمثابرة، مكّننا من بناء علاقات طويلة الأمد قائمة على الثقة مع عملائنا في حوالي 30 دولة حول العالم.

تحرص FMP دائمًا على تعزيز الشراكات العالمية، وتلتزم بتقديم استشارات متخصصة وحلول مُخصصة تُلبي احتياجات عملائنا المتنوعة. لا يقتصر عملنا على توريد المنتجات فحسب، بل نهدف إلى بناء علاقات متينة تُسهم في نجاح كل مشروع. سواءً كنتم بحاجة إلى حلول مبتكرة لمبادرة جديدة أو دعم مستمر لنظام قائم، فإن FMP هنا لمساعدتكم في مواجهة تحدياتكم التقنية وضمان استمرار نجاحكم.

المؤلف: CX