The 10019 Effective Double Acting Stainless Steel Hydraulic Cylinder is designed for superior performance and durability in demanding environments. This hydraulic cylinder combines advanced engineering with high-quality materials, making it an essential component for various industrial and agricultural applications.

الميزات الرئيسية:

- Double Acting Design:

The double acting mechanism allows for efficient operation in both extension and retraction, providing smooth and controlled movement. This enhances precision in tasks such as lifting, pushing, and pulling, making it ideal for a range of applications. - Stainless Steel Construction:

Constructed from high-grade stainless steel, the 10019 hydraulic cylinder offers exceptional resistance to corrosion and wear. This durability ensures reliable performance even in harsh conditions, making it suitable for outdoor and industrial use. - High Load Capacity:

Engineered to handle substantial loads, this hydraulic cylinder delivers powerful lifting and pushing capabilities. Its high load capacity enhances productivity and efficiency in various operations, from construction to agricultural tasks. - Versatile Applications:

The 10019 hydraulic cylinder is suitable for a wide array of applications, including material handling, agricultural machinery, and industrial equipment. Its versatility makes it a valuable tool for professionals in multiple sectors. - Compact and Lightweight:

The cylinder’s compact design allows for easy installation in tight spaces without compromising performance. Its lightweight nature facilitates maneuverability, making it suitable for various equipment setups.

Technical Specifications:

| مواصفة | وصف |

|---|---|

| حجم التجويف | Customizable |

| Stroke Length | Various options available |

| Maximum Pressure | Up to 3000 PSI |

| مادة | High-quality stainless steel |

| Connection Type | Flanged or threaded |

Working Principle:

The 10019 Double Acting Stainless Steel Hydraulic Cylinder operates on the principle of hydraulic fluid pressure. When hydraulic fluid is pumped into the cylinder, it exerts force on the piston, generating linear motion in both directions. This effective power transfer enables precise control over various tasks, enhancing operational efficiency.

In summary, the 10019 Effective Double Acting Stainless Steel Hydraulic Cylinder is a reliable and efficient solution for demanding applications. Its durable construction, high load capacity, and versatility make it an essential tool for professionals seeking to improve productivity and performance in their operations.

مزايا أسطوانة نوع تي الملحومة

-

- زيادة القوة: تتميز أسطوانات "تي" الملحومة بمتانتها العالية، مما يجعلها مناسبة للتطبيقات التي تتطلب رفعًا ثقيلًا. تضمن عملية اللحام المستخدمة أثناء تصنيع هذه الأسطوانات خلوها من نقاط الضعف وقدرتها على تحمل الضغط والإجهاد العاليين.

عند الضغط على الأسطوانة، يتوزع الضغط بالتساوي على كامل سطحها، مما يجعلها مقاومة للتشوه. تضمن هذه الميزة حفاظ الأسطوانة على شكلها وسلامتها الهيكلية حتى في الظروف القاسية.

-

- منع التسرب: صُممت أسطوانات اللحام على شكل حرف T لمنع التسرب. تضمن عملية اللحام المستخدمة أثناء التصنيع إحكام إغلاق الأسطوانة تمامًا وخلوها من أي تسربات محتملة. هذه الميزة تجعلها مناسبة للاستخدام في التطبيقات التي قد يُسبب فيها التسرب أضرارًا أو إصابات جسيمة.

تكون المفاصل الملحومة ناعمة، ولا تحتوي على أي شقوق أو أخاديد يمكن أن تتراكم فيها الحطام أو الأوساخ، مما يقلل من خطر التآكل والتلف للأسطوانة.

-

- قابلة للتخصيص: يمكن تخصيص أسطوانات اللحام على شكل حرف T لتناسب تطبيقات محددة. تتوفر الأسطوانات بأحجام وأشكال مختلفة، ويمكن تصنيعها لتلبية المتطلبات الخاصة بكل تطبيق.

تتيح عملية التخصيص تحسين أداء الأسطوانة، مما يضمن ملاءمتها للتطبيق المطلوب. هذه الميزة تجعل أسطوانات "تي" الملحومة مثالية للاستخدام في مختلف التطبيقات الصناعية، بما في ذلك البناء والتعدين ومناولة المواد.

-

- فعّالة من حيث التكلفة: تُعد أسطوانات "تي" الملحومة اقتصادية مقارنةً بأنواع الأسطوانات الأخرى. فعملية التصنيع بسيطة، مما يجعلها أقل تكلفة من أنواع الأسطوانات الأخرى.

علاوة على ذلك، تُقلل قوة ومتانة أسطوانات اللحام ذات الشكل الثلاثي من الحاجة إلى الإصلاحات والاستبدالات المتكررة، مما يوفر تكاليف الصيانة. هذه الميزة تجعلها خيارًا شائعًا للعديد من الصناعات، وخاصةً ذات الميزانيات المحدودة.

-

- زيادة الكفاءة: تتميز أسطوانات "تي" الملحومة بكفاءة وفعالية عاليتين. يضمن تصميم الأسطوانة نقل القوة المطبقة مباشرةً إلى الحمل، مما يقلل من هدر الطاقة ويزيد من الكفاءة.

تتميز الوصلات الملحومة بالقوة والمتانة، مما يقلل من الانحراف ويضمن حفاظ الأسطوانة على شكلها وسلامتها الهيكلية حتى في الظروف القاسية. هذه الميزة تجعل أسطوانات "تي" الملحومة مثالية للاستخدام في التطبيقات التي تتطلب كفاءة وموثوقية عاليتين.

تطبيق أسطوانة من النوع تي الملحومة

مقدمة

Welded tee type cylinder is a type of hydraulic cylinder that is commonly used in industrial applications. It is designed to provide high force output in a compact and cost-effective package. This type of cylinder consists of a welded tee and a piston rod that is attached to the tee. The tee is connected to the barrel of the cylinder and contains a piston that moves back and forth inside the barrel to generate force.

مزايا أسطوانة نوع تي الملحومة

There are several advantages to using a welded tee type cylinder in industrial applications:

- Compact design: Welded tee type cylinders are designed to be compact, which makes them ideal for use in applications where space is limited.

- High efficiency: Welded tee type cylinders are highly efficient, which means that they can generate a large amount of force with minimal energy input.

- Durable: Welded tee type cylinders are designed to be highly durable, which means that they can withstand harsh operating conditions and last for a long time.

- Cost-effective: Welded tee type cylinders are cost-effective, which means that they provide good value for money.

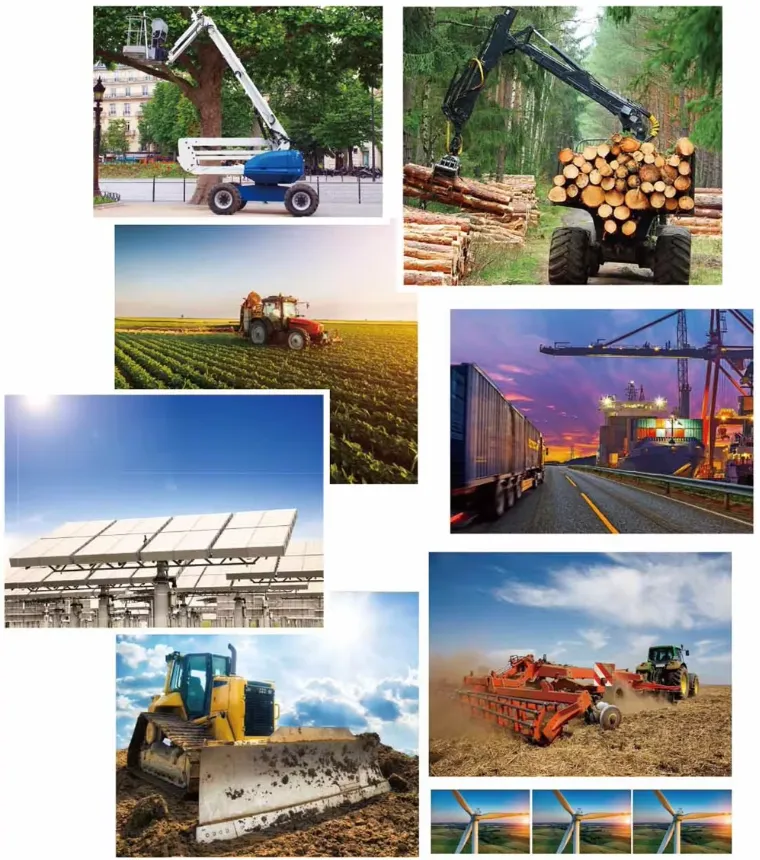

Applications of Welded Tee Type Cylinder

There are many applications for welded tee type cylinders in various industries, including:

- Manufacturing: Welded tee type cylinders are used in manufacturing to operate machinery, move heavy loads, and shape metal parts.

- Agriculture: Welded tee type cylinders are used in agriculture to operate hydraulic systems on tractors, harvesters, and other farm equipment.

- بناء: Welded tee type cylinders are used in construction to operate machinery such as cranes, excavators, and backhoes.

- Mining: Welded tee type cylinders are used in mining to operate hydraulic systems on heavy equipment such as bulldozers, loaders, and rock drills.

- Transportation: Welded tee type cylinders are used in transportation to operate hydraulic systems on trucks, buses, and other vehicles.

In conclusion, welded tee type cylinders are an important component in many industrial applications. They are designed to be compact, efficient, durable, and cost-effective, making them an ideal choice for a wide range of applications. Whether you are operating machinery in a manufacturing plant, farming equipment on a farm, or heavy equipment in a mine, welded tee type cylinders can help you get the job done efficiently and effectively.

حول FMP

FMP, with over 30 years of establishment in Italy, is a leading manufacturer and supplier of Hydraulic Cylinders. Equipped with more than 100 advanced machines including automatic gas shielded welding machines, deep hole boring machines, and CNC lathes, we ensure precision and efficiency in our production process. Our commitment to quality is reflected in our rigorous processing and inspection procedures, guaranteeing superior products for our valued customers.

1) Design Service: Our experienced design team specializes in universal shaft product design and development. Whether you require new products or improvements to existing ones, we are here to support you.

2) Product Service: From raw materials to cutting, rough processing, testing, cleaning, assembly, packaging, and transportation, we oversee every step to ensure the highest quality standards are met.

3) Sample Process: We offer sample development according to your specific requirements. Our dedicated team constantly modifies samples to meet your needs, guaranteeing product excellence.

4) R&D: As the market evolves, we stay at the forefront of innovation. We study new market demands and develop new models to meet the ever-changing needs of our customers.

5) Customization: At FMP, we understand that each customer is unique. We offer customized hydraulic cylinders tailored to your exact specifications, ensuring optimal performance and customer satisfaction.

المؤلف:CX